solutions

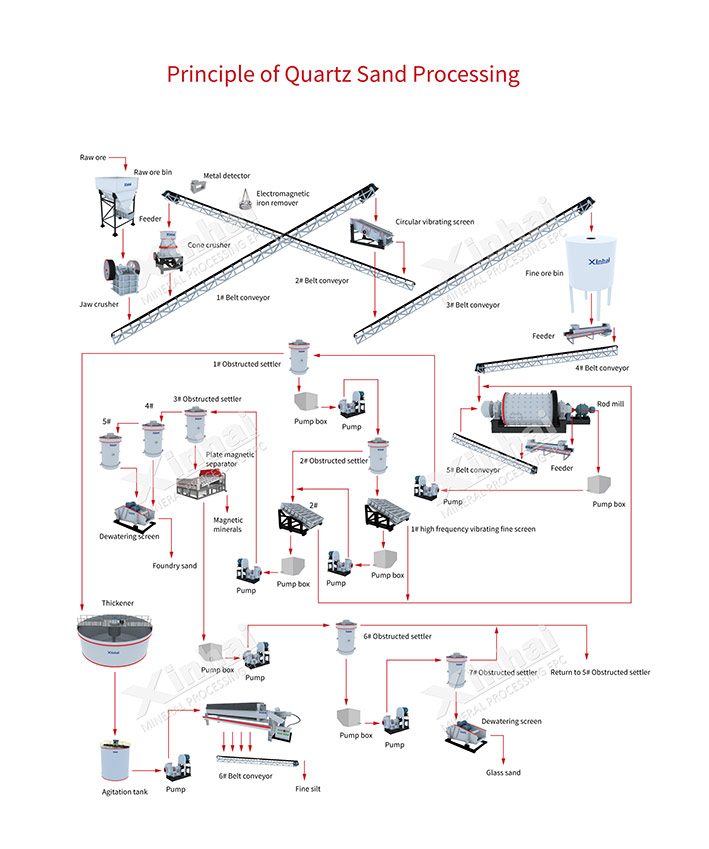

[Introduction]: Quartz sand purification is removal of a small amount of impurities and the high difficulty separation technique to obtain refined quartz sand or high purity quartz sand. The purification technologies of quartz sand at home and abroad are washing, classifying and desliming, scrubbing, magnetic separation, flotation, acid leaching, microbial leaching, etc.

[Improvement]: Quartz sand dressing Production Line is suitable for quartz sand containing iron or mica.

The SiO2 grade in quartz sand decreases by quartz sand size becoming finer, so washing and desliming of crude quartz sand is necessary before next step.

Scrubbing is the way to remove film iron and impurity minerals on the surface of quartz by mechanical force and crush these mineral aggregate. The quartz sand gets further purification by classification. There are two kinds of methods, including rod scrubbing and mechanical scrubbing.

The separation of mica and quartz is difficult, but there are two effective methods: anionic collector in acid condition and anionic - cationic collector in alkaline condition. The purification of quartz sand can reach 99% after scrubbing, desliming, magnetic separation and flotation.

Dilute acid had a significant effect on removing iron and aluminum, and concentrated acid for the removal of titanium and chromium, and mixed acid for mineral impurity. Control various factors of acid leaching should be based on quartz final grade requirements, and as far as possible reduce the acid concentration, temperature and dosage to achieve quartz purification.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.