Xinhai's integrated mining solutions are oriented toward the full life cycle of mines, covering the complete process from mining test research, mine design and planning, mining engineering construction, to operational management. Leveraging the technical expertise of our Mining Research Institute and extensive EPC experience, we integrate scientific design, intelligent equipment, green construction, and lean operation to deliver safe, efficient, and sustainable end-to-end mining solutions.

Xinhai provides a full suite of testing services for both open-pit and underground mines:

We evaluate slope angles and stability through sample collection and mechanical analysis, providing comprehensive analysis reports.

Includes studies on backfill material properties, slurry transport, settling and thickening, forming a systematic database and design basis for underground backfill system construction.

Validate explosive usage, blasting parameters, and process rationality. Combined with vibration monitoring and safety assessments, we optimize blasting plans to improve crushing efficiency and reduce environmental impact.

Relying on the capabilities of Xinhai Mine Design Institute, which holds Class B metallurgical design qualifications, our design services include:

Comprehensive evaluation of resources, mining conditions, infrastructure, and market outlook, forming conceptual plans and cost estimates to support investment and approval.

Ensure efficient resource utilization and ecological protection, while assisting with permitting and regulatory approvals.

Deliver detailed design documents covering civil, electrical, water supply, drainage, and steel structures, in compliance with international standards for direct construction execution.

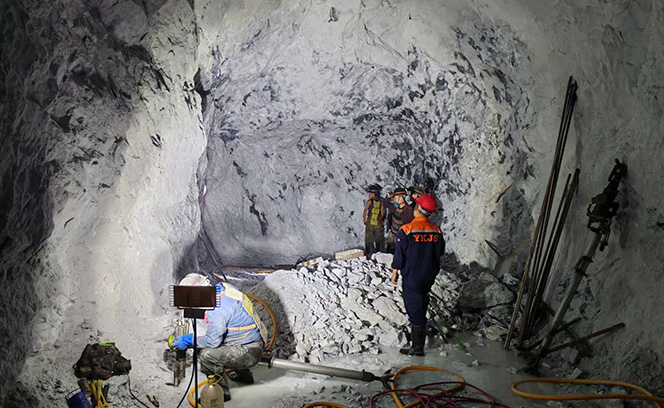

Xinhai's construction services are highly mechanized and automated. They covering mine infrastructure development, equipment procurement, and supporting system installation, ensuring safe, efficient, and compliant project execution.

Shafts, inclines, adits, ramps, etc.

Electrical, water supply and drainage, HVAC, dust removal, etc.

Underground haulage systems, power and communication networks

Monitoring and surveillance, personnel positioning, emergency refuge, self-rescue, and communication systems

Xinhai offers full-lifecycle contracting and operation services:

Drilling and blasting management, mine planning, and production organization

Ore haulage, ventilation and drainage, power supply, ground control, equipment operation and maintenance, personnel management

Safety and emergency management, environmental protection and waste treatment, cost control and benefit analysis, with support for digitalization and innovative mining applications

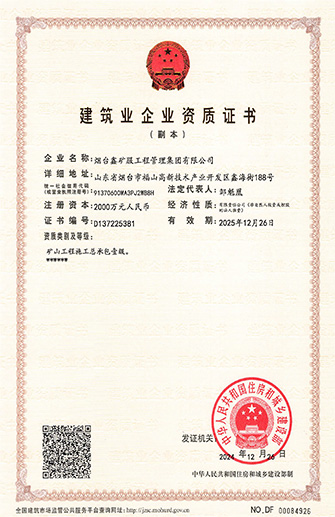

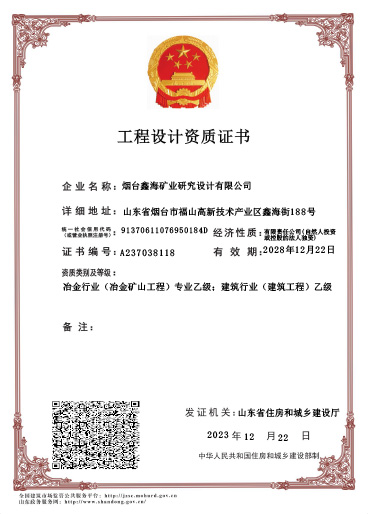

Holding Class I General Contracting and Class B Design certifications, with expertise across geology, mining, civil, electrical, ventilation, and more.

Both surface and underground projects adopt mechanization, applying automation to key processes, enabling intelligent mine construction.

Certified professionals and experienced crews work seamlessly together to ensure safe and efficient project execution.

Powered by "Three Institutes and Five Centers," with 500+ experts covering beneficiation, mining, tailings, and automation.

Following the "one mine, one solution" principle, avoiding standardized templates and ensuring optimal investment efficiency.

In 2024, Xinhai signed a 3-year fixed-price contract for a 500,000 t/a wollastonite project in Jiangxi, worth nearly RMB 100 million. Mining and tunnel works started quickly, combining production with infrastructure to ensure safe and sustainable operation.

Xinhai serves as EPC contractor for a 4,000 t/d molybdenum project in Hebei. Covering both underground and open-pit mining, the project applies efficient blasting methods and ensures smooth transition from construction to production with on-time delivery.