products

[Introduction]: A bar flotation cell with self-air suction and mechanical agitation

[Capacity]: 1.5~4 m³/min

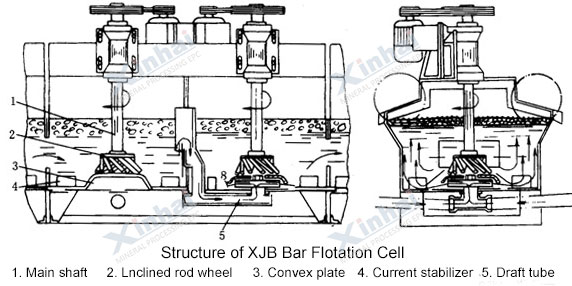

[Improvement]: There is a convex bench and an arc-shaped steady flow plate. The convex bench works as the guide groove, which makes the mixture of air and slurry rush to the bottom of tank. And then with the steady flow plate the mixture spreads in the tank uniformly, moving in the shape of W.

The bar flotation cell has air inflation agitation group consisting of oblique rod wheel, convex plate, arc stabilizer, etc. The impeller is consisted of a disc and 12 bevel cone bars. The rotating speed of bevel cone bar gets faster and faster while downing and agitation force gets stronger accordingly.

The negative pressure generated by the revolving impeller or rod wheel is used to suck the air from the hollow shaft, and then the flotation wheel divides it to form tiny bubbles, and then the impeller or rod wheel strongly stirs and throws it, so that the slurry and air are fully mixed, and under the action of the slanting rod of the flotation wheel, the useful mineral particles, which are treated with flotation reagents (collectors), are selectively attached to the bubbles and float to the pulp surface, and then scraped into the concentrate tank by the scraper, thus completing the separation.

| Model | Tank Type | Effective Volume(m3) | Capacity(m3/min) | Impeller Diameter(mm) | Impeller Rotation Speed(r.p.m) | Motor Power for Agitation(kw) | Motor Power for Scraper(kw) | 4 Tank Weight(kg) |

| XJB-1 | Suction Tank | 1 | 1.5-1.7 | 400 | 440 | 5.5 | 1.5 | 5344 |

| XJB-1 | Direct Flow Cell | 1 | 1.5-1.7 | 410 | 410 | 4 | 0.8 | 5344 |

| XJB-1D | Suction Tank | 1 | 1.5-1.7 | 400 | 440 | 5.5 | 1.5 | 5479 |

| XJB-1D | Direct Flow Cell | 1 | 1.5-1.7 | 410 | 410 | 4 | 0.8 | 5479 |

| XJB-2 | Suction Tank | 2 | 1.5-1.4 | 450 | 360 | 15 | 1.1 | 9071 |

| XJB-2 | Direct Flow Cell | 2 | 1.5-1.4 | 540 | 360 | 11 | 1.1 | 9071 |

| XJB-2D | Suction Tank | 2 | 1.5-1.4 | 450 | 360 | 15 | 1.1 | 9320 |

| XJB-2D | Direct Flow Cell | 2 | 1.5-1.4 | 540 | 360 | 11 | 1.1 | 9320 |

| XJB-4 | Suction Tank | 4 | 2.0-4 | 700 | 280 | 18.5 | 1.1 | 16325 |

| XJB-4 | Direct Flow Cell | 4 | 2.0-4 | 510 | 280 | 18.5 | 1.1 | 16325 |

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.