solutions

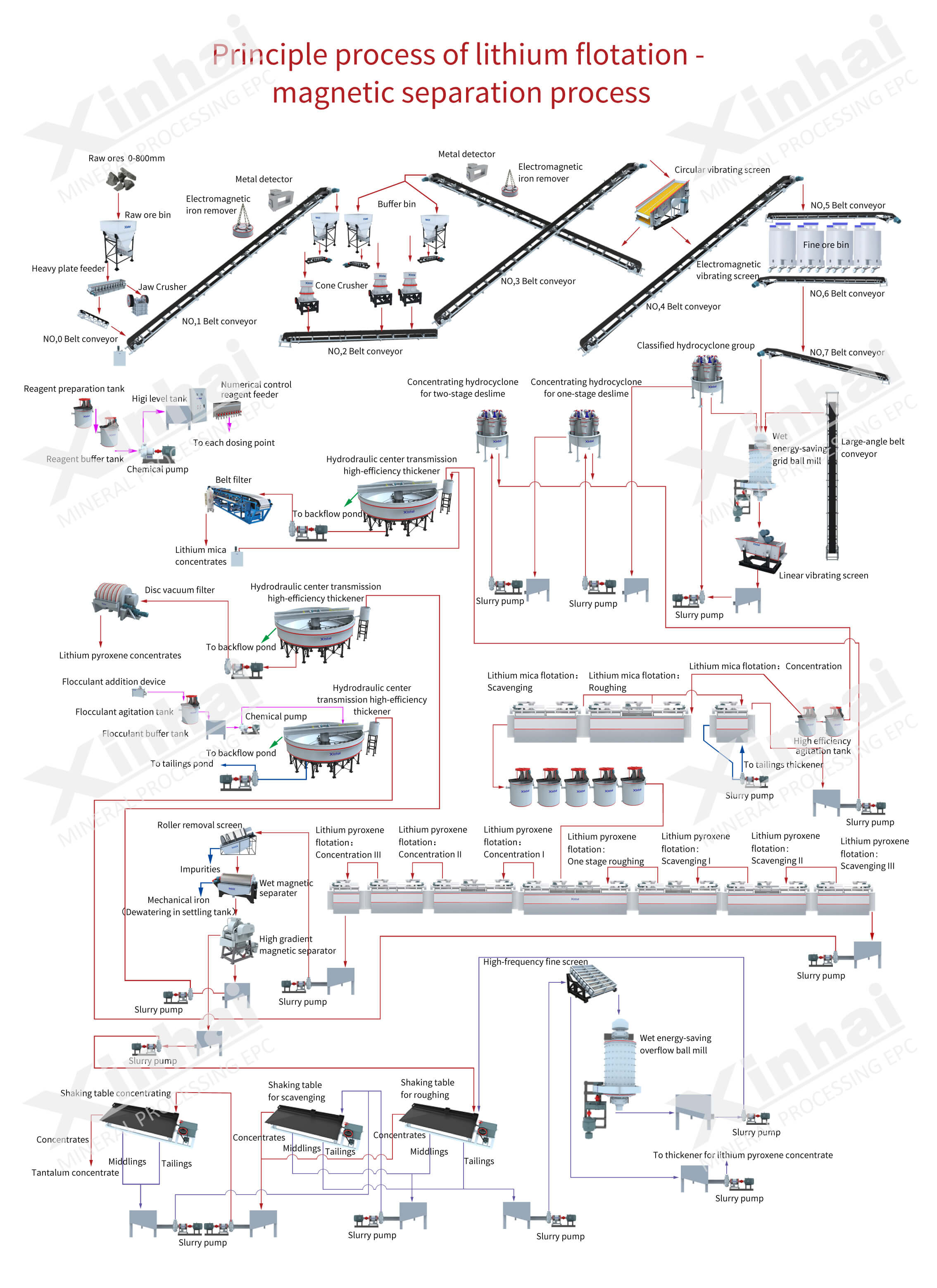

[Introduction]: Because different types of lithium ores have different properties, and the low content of lithium oxide in the minerals is low, and the mineral composition is different, the beneficiation processes of lithium ore are also different. At present, the main lithium ore beneficiation methods include:flotation separation method, magnetic separation method, heavy medium beneficiation method and combined beneficiation method.

[Improvement]: The lithium ore mineral beneficiation process designed by Xinhai Mining is mainly suitable for treating spodumene and lidumicite lithium minerals.

After lithium ores ground (avoid over-grinding as much as possible), add starches, dextrins and other reagents to discourage the upward movement of lithium ores. Strong stirring in highly concentrated alkaline media, then scrubbing and desliming several times. The lithium concentrates can be floated by oleic acid and its soap salt-trapping agents. The gangue minerals are left in flotation tank. The inhibitors are not additional required in this procedure.

It creates an alkaline environment with lime. Starch and dextrin are added to inhibit the float of lithium. At the same time, cationic trapping agents are added to float the silicate vein minerals. The products in flotation are lithium concentrates. If there are iron minerals in lithium ores, foaming agents(such as HF and resin acid salts) can be added to remove iron and other impurities furtherly.

Magnetic separation is commonly used to deal with iron impurities in lithiophane. These minerals are weakly magnetic. They can be removed by strong magnetic separation to require low-iron lithiophane concentrates.

For spodumene with a relatively coarse crystal size, the heavy-media beneficiation method can be applied to make lithium ore a heavy mineral product.Mix the lithium ore after washing and desliming with heavy-media (there are two types of heavy medium: heavy liquid and heavy suspension, here mainly refer to heavy suspension), and feed it into the heavy medium cyclone at a pressure of 0.05-0.20Mpa for separation. Heavy products and light products can be separated. The heavy products become lithium concentrates after being stripped through the stripping sieve.

Oxidized paraffin soap and naphthenic acid soap are used as a combined collector first, and NaOH is a pH regulator. The one-coarse and one-fine flotation process is used in the alkaline mineral slurry to obtain spodumene concentrate. Then, remove iron by strong magnetic separation to get concentrate with low iron content.

Ground materials after slurry adjustment are sent to gravity separation (remove tantalum, niobium and other products), gravity separation tailings after desliming by concentrator. Gravity separation tailings are concentrated and deslimed by thickener.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.