Graphite, as a crystalline carbonaceous mineral, is widely used in the fields of machinery, metallurgy, petrochemical industry, light industry, electronics, electrical appliances, national defense, military industry and aerospace. As the uses of graphite continue to expand, its mineral processing technology and equipment have also made significant progress. The graphite mineral beneficiation process mainly includes three core stages: crushing, grinding and separation. Each stage will use corresponding equipment according to the specific type and properties of graphite ore.

Graphite mineral is usually of moderate hardness or medium-hard but soft, which makes the crushing process design of the beneficiation plant relatively simple. For graphite ores with a raw ore grade of 2% to 10%, three-stage open circuit, two-stage open circuit or one-stage open circuit crushing processes can be selected. Some new beneficiation plants also use a three-stage one-closed circuit crushing process. For small graphite ores with a high degree of weathering, grinding can be carried out directly without crushing.

In the selection of crushing equipment, jaw crusher is often used as the first coarse crushing equipment of graphite ore due to its high production capacity, large crushing ratio and high crushing efficiency. It can effectively reduce the particle size of graphite ore and lay the foundation for subsequent grinding operations. The second and third stage crushing mostly use cone crusher for medium and fine crushing to further refine the graphite ore to meet the requirements of the subsequent grinding process. After crushing, a circular vibrating screen is usually used for fine screening to ensure the effective separation of graphite ores of different particle sizes.

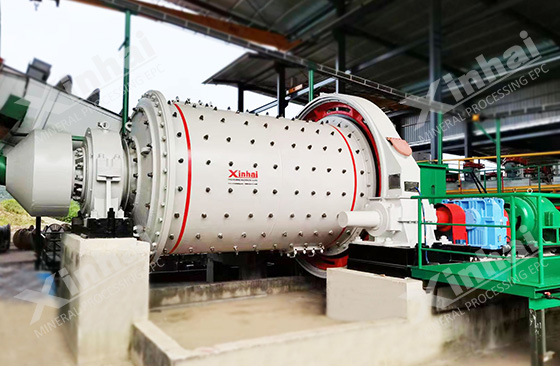

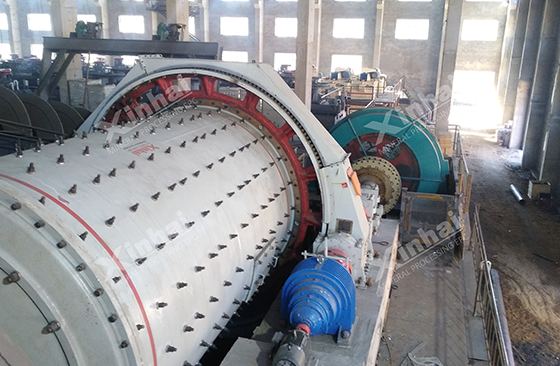

Due to the flake structure of graphite mineral, it is necessary to ensure that the graphite concentrate has as many large flakes as possible during the grinding stage to increase the large flake rate of the concentrate. At this stage, the shape of the grinding media and the type of mill have a great influence on the large flake rate of the graphite concentrate. Commonly used grinding equipment includes rod mills and vertical stirred mills.

Rod mills use the full length of the steel rod to grind the material, with uniform force, uniform product particle size, less over-crushing, and help maintain the integrity of large flakes. Vertical stirred mill is a device specially developed for the characteristics of graphite ore, with the combined advantages of tower mills, flaking machines and sand mills. Graphite vertical mills can effectively grind materials to 10 microns or finer, with low energy consumption, which can save more than 50% energy compared with ordinary horizontal ball mills. The product particle size of this equipment is adjustable, and it can be produced intermittently, cyclically, and continuously; it runs smoothly and reliably, with low vibration and noise below 85 decibels; it has a simple structure, is easy to operate and maintain, occupies a small area, and has low infrastructure investment.

According to the characteristics of graphite mineral, flotation is the main separation method for crystalline graphite. Graphite ore itself has good floatability, so flotation can effectively recover graphite. Commonly used equipment in the flotation process includes mechanical agitation flotation machine and aeration agitation flotation machine.

Mechanical agitation flotation machine

Mechanical agitation flotation machines generate bubbles and stir the pulp through impellers and stators. This type of equipment can be self-aspirating, that is, air is sucked near the mechanical stirring device at the bottom of the flotation cell. Common mechanical agitation flotation machines include SF, JJF and BF flotation machines. The impeller of the BF flotation machine is composed of a closed double truncated cone, which can produce strong pulp circulation, with large air suction and low power consumption. Each flotation cell has the triple functions of air suction, pulp suction and flotation, and forms a flotation circuit without any auxiliary equipment. It is horizontally configured for easy process adjustment.

Aerated agitator flotation machine

Aerated flotation machine is a highly efficient flotation equipment that mainly relies on external air compressors to provide air. Common aerated flotation machines include KYF, XCF, GF and CLF coarse-grained flotation machines. CLF flotation machine is suitable for processing materials with high pulp density and high concentration, and can effectively improve the recovery rate of coarse and heavy graphite ore. KYF and XCF are suitable for flotation of fine-grained graphite ore, without the need for foam pumps, with simple configuration and saving infrastructure costs.

In actual ore dressing plants, the selection of graphite mineral dressing process methods and graphite ore production line equipment should be based on the properties of graphite ore. First, ore dressing tests should be carried out, and then suitable graphite ore dressing processes and complete sets of graphite mineral dressing equipment should be designed according to actual conditions through test analysis, so as to obtain more ideal graphite concentrate.

1. Heilongjiang 3000tpd Graphite Ore Concentrator Project

2. Vietnam 800tpd Graphite Ore Concentrator Project

3. Shanxi 300,000tpa Quartz Sand Concentrator Project

4. Zimbabwe 2 million tpa Spodumene Ore Concentrator Project

5. Uganda 720tpd Phosphate Ore Concentrator Project

6. Mongolia 800tpd Fluorite Concentrator Project

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.