Based on 20 years of experience in mineral processing industry, Xinhai has been committed to the development and innovation of froth flotation process, aiming at providing professional flotation cell and comprehensive service, including from previous beneficiation test analysis, middle flotation process design and equipment selection, and later installation and debugging. Currently, Xinhai has provided the advanced professional Xinhai froth flotation process for many mineral processing projects at home and abroad.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

If you have any questions, please contact us by the following ways, and we will provide you with better help!

Strengthening mineral hydrophobic, floatability and adsorbability

Such as: xanthate and aerofloat

Promote or inhibit mineral buoyancy; Adjust pulp PH and ion composition

Such as: inhibitor, activator and acid-base regulator

Promote pulp form stable foam

Such as: pine oil, cresol, fatty alcohol

Compared with common flotation reagents, Xinhai special flotation reagents not only enhances the mineral surface hydrophobicity, mineral adhesive fastness and selectivity on the bubble, but also improves more 25% mineral flotation separation speed, which plays a very important role in flotation separation efficiency and flotation index.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

In May 2016, Iranian client commissioned Xinhai Mine Research Institute to conduct beneficiation test after collected 50kg samples in the site. After tested the ore properties of sample ore, Xinhai lab concluded that the ore was gold-bearing quartz vein deposit, the metal mineral were pyrite, limonite and natural gold. The ore grade is 5.61g/t.

Xinhai mineral processing plan: After finished the test in July, Xinhai Mine Research Institute carried on the preliminary exploration of its processing conditions. After compared froth flotation process with cyanide leaching process, Xinhaia Mine Research Institute found that the gold recovery rate in froth flotation process was far higher than in cyanide leaching process. Therefore, after consulting with the client, Xinhai decided to adopt two-stage closed circuit crushing, one-stage grinding and single froth flotation process to get the gold concentrate. After the grinding, then one roughing, three scavenging, three concentration, the process got 87.16% recovery rate of gold concentrate.

According to the beneficiation test and froth flotation process requirements, Iran 300tpd gold froth floatation plant needed the following flotation cell model:

| Equipment Name | Type | Unit Quantity | Power (KW) | Voltage (V) |

| Flotation cell | SF-8 | 3 | 3*30 | 380 |

| Flotation cell | JJF-8 | 7 | 7*22 | 380 |

| Flotation cell | SF-4 | 3 | 3*15 | 380 |

| Flotation cell | JJF-4 | 9 | 9*11 | 380 |

| Flotation cell | SF-2.8 | 33 | 33*11 | 380 |

If you have any questions, please contact us by the following ways, and we will provide you with better help!

In August 2016, Xinhai sent professional engineers to the site to learn about the mineral resources and construction conditions. Considered its location, mineral characteristics, the project needs to solve the following problems:

1) The project was located in the Iranian plateau, which was about 2,000 meters above sea level. The weather was cold in the winter, which needed to take into consideration;

2) The investment fund was limited, so the project needed to be completed as soon as possible.

1) Adopted reasonable and compact layout. Makes full use of the high difference to complete self-flow layout in the workshop design, meanwhile, makes the industrial plants as compact and warm as possible, which is easy to produce in winter.

2) Optimized froth flotation process, improved efficiency. According to ore characteristics, Xinhai timely controlled the dosage of flotation reagents, especially the dosage of xanthate, strictly controlled concentration density, and greatly improved the gold concentrate grade. At the same time, in order to complete the project construction fast and efficient, Xinhai personnel decisively abandoned home holiday arrangement, worked hard in the first line, so completed the construction of plant workshop 15 days in advance.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

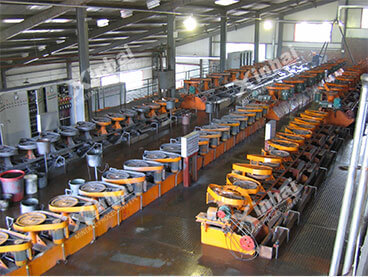

Xinhai production plant was producing flotation cell of this project. The flotation cell of this project was finished in Xinhai manufacturing plant, and was prepared for packaging.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

After manufactured and purchased the flotation cell, Xinhai installation and commissioning technicians started equipment installation and commissioning.

To help Iranian workers to operate as soon as possible, Xinhai technicians showed on-site training for plant workers, explained equipment operation notes, helped customers quickly establish own technical team, laid foundation for later stable operation.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

In Iran 300 tpd gold froth flotation project, the ore grade was 5.61 g/t, gold concentrate grade was 78.85 g/t, flotation recovery rate was as high as 87.16%, the final recovery rate was up to 87.16%,the customers gave high praise for these results. From the beneficiation test, mine design, equipment manufacture, installation and debugging to the worker training and standard reached, Xinhai provided a series of froth flotation process service.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

If you have any questions, please contact us by the following ways, and we will provide you with better help!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.