As mining grows bigger and smarter, Xinhai's KYF series Large Circular Flotation Machine steps up with fresh designs and clever upgrades. We've reworked the tank structure, drive systems, key parts, production methods, installation process, and smart controls to deliver equipment that's efficient, dependable, and user-friendly.

This article walks you through the standout features of Xinhai's Large Circular Flotation Machine, showing how it tackles your mineral processing headaches and boosts flotation performance. Let's dive in!

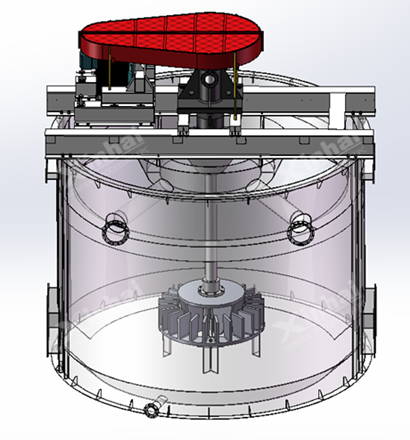

Xinhai's Large Circular Flotation Machine brings a new approach to tank design, making slurry flow smoother, air spread better, and froth collection easier. It solves common issues like sand buildup and uneven stress that plague older flotation machines.

1. Circular Tank with Cone Bottom: The tank's round shape and cone-shaped bottom spread air evenly and keep slurry moving. This prevents sand from settling at the bottom, a frequent problem in older setups. As a result, it lifts recovery rates, ensuring more valuable minerals are captured.

2. Dual Circular Froth Launders and Froth Cone: Each tank has two round froth launders and a froth cone. These cut down the distance froth travels to reach the collection point. They also stop froth from pooling in one spot, which can mess up the process. This setup ensures smooth froth flow and improves the quality of the concentrate.

3. Uniform Stress Distribution: The circular tank spreads stress evenly across its surface. Unlike older designs, it avoids weak spots where stress piles up. This lets us use less material, making the machine lighter and longer-lasting, saving you maintenance costs down the road.

4. Easy Installation & Eco-Friendly Construction: We do all the welding in our factory, so on-site work is just bolting parts together. This cuts installation time and reduces worker effort. It also keeps the site clean, with no welding fumes or mess harming the environment. If repairs are needed later, taking things apart is a breeze

The heart of Xinhai's Large Circular Flotation Machine lies in its beefed-up parts, built to last and perform under tough conditions.

1. Main Shaft Design: The main shaft, where it touches the slurry, is wrapped in a 5mm-thick rubber sleeve. This sleeve resists acid and oil, keeping the shaft safe from wear. It lasts way longer than unprotected shafts, cutting down on replacement costs.

2. Main Bearing: We use top-notch bearings from brands like SKF, TIMKEN, and FAG. These handle heavy loads without breaking a sweat, keeping the machine running smoothly even in demanding mining setups.

3. Impeller & Stator: The impeller has backward-angled blades and a high-speed centrifugal design. It moves a lot of slurry with low pressure, saving energy. The stator, with its low-damping, straight-suspension setup, opens up more space for slurry to flow. This reduces resistance and lowers power use, making the machine more efficient.

4. Mid/Tailings Box: The mid and tailings boxes use a dual-cone valve and a pneumatic control device. These make liquid level adjustments super precise and reliable, so the flotation process stays steady.

5. Pulley: We use taper bush pulleys, which are easy to check and swap out on-site. This saves time during maintenance, keeping your operation running with less downtime.

Xinhai uses cutting-edge tools and methods to build the Large Circular Flotation Machine, ensuring top quality and fixing issues like sloppy machining or installation errors.

1. Fully Automatic CNC Laser Cutting. We cut tank plates and connection holes with automatic CNC laser machines. The cuts are smooth and precise, with almost no warping. This ensures tight fits between the tank, feed box, intermediate box, and tailings box, with gaps no bigger than 3mm.

2. Automatic Welding & Calibration. Our dedicated welding platforms and automatic welding gear shape the tanks perfectly. After welding, we use an infrared level calibrator to check the tank's alignment. The overflow weir's parallelism stays within ±5mm per meter, ensuring the machine runs smoothly and consistently.

Xinhai's Large Circular Flotation Machine isn't just about tough hardware—it's packed with smart tech to make mineral processing easier and more efficient. These tools replace guesswork with real-time data and automation.

1. Slurry Level & Aeration Control

Each flotation bank comes with a slurry level control system. It includes a detection device, a pneumatic discharge actuator, and a PLC control box. Our "cooperative optimization" approach uses feedforward control to quickly handle disruptions. This keeps liquid levels steady, improving the flotation process's reliability.

2. Froth Image Analyzer

This tool uses computer vision to study froth in real-time. It tracks things like froth speed, color, size, texture, and overflow height. Unlike old-school manual checks, which can be inconsistent, this gives accurate data fast, helping you fine-tune the flotation process.

3. Online Slurry Grade Analyzer

Using X-ray fluorescence (XRF) tech, this analyzer checks the slurry's element content in real-time, from 0.001% to 100%, with an error of just 0.5% to 10%. It guides processes like flash flotation, roughing, cleaning, and scavenging, boosting recovery rates and ensuring high-quality concentrates.

4. Intelligent Reagent Feeder

This feeder delivers reagents with pinpoint accuracy (1:1000 range, ±0.5% error). It provides steady output without surges and alerts you to issues like clogged pipes or broken diaphragms. This cuts reagent waste and improves flotation results, saving money and boosting performance.

5. Flotation Optimization Control System

This system ties together the froth analyzer, grade analyzer, level control, and reagent feeder. It builds smart models to set the best levels for liquid, air, and reagents. The DCS system makes these adjustments automatically, leading to better flotation outcomes with less effort.

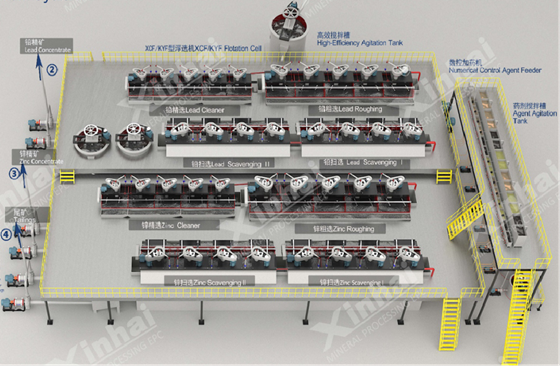

Large-scale and smart solutions are the future of mining. With over 20 years in the mineral processing game, Xinhai has a crack team of flotation experts and the ability to build big equipment. Our Large Circular Flotation Machine has worked wonders in mines worldwide, delivering real value.

Take our recent project in Zambia, for example. We teamed up again with a copper mine processing 3.5 million tons per year. They needed reliable equipment to handle tough ore and boost efficiency. Xinhai supplied 17 KYFⅡ-130 Large Circular Flotation Machines, 3 XCF-40 Flotation Machines, 4 KYF-40 Flotation Machines, 2 φ6500×6500 High-Efficiency Agitators, and a full-on automated control system. The mine saw higher recovery rates, lower energy costs, and smoother operations, proving our gear can handle real-world challenges.

Xinhai's Large Circular Flotation Machine shines with its smart tank design, sturdy parts, precise manufacturing, clever tech, and easy setup. It tackles big mining problems like low recovery, high energy use, and tricky maintenance, all while being kind to the environment.

Looking for a flotation solution that's efficient, reliable, and smart? Reach out to Xinhai's engineering team! We're ready to tailor a plan for your mine, whether you're dealing with complex ores or aiming to cut costs. Call us to get started. Let's make your mineral processing operation a success!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.