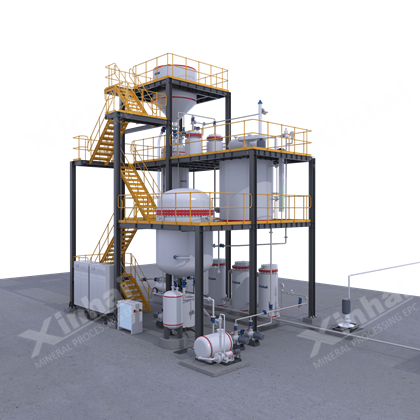

In modern gold production, the desorption electrolysis system is a key piece of equipment to recover solid gold from gold-loaded carbon. Based on the traditional two-layer system, Xinhai has developed the three-layer desorption electrolysis system. It maintains efficient and stable gold recovery performance while introducing structural optimization and design upgrades. The result is easier, safer, and more economical operation for mining clients.

The traditional two-layer desorption electrolysis system is widely used, but its platform design creates difficulties for plant operators. Workers often face inconvenient and unsafe conditions during operation. Xinhai's three-layer system solves this by upgrading the platform design from two layers to three. This small but critical change eliminates pain points and makes every operation easier and safer.

1. User-Friendly Valve Operation

In two-layer systems, the upper valve of the desorption column is set too high. Operators often need tools or elevated support to reach it, which is inconvenient and unsafe. The three-layer system positions the valve at a comfortable height on the operator's platform. Staff can complete valve operations directly and safely without any extra tools.

2. Easier Chemical Feeding

In traditional two-layer systems, the desorption liquid tank sits above the platform. Operators must lift chemicals up to the tank opening, which requires heavy physical effort and risks spillage. The three-layer system moves the desorption liquid tank below the platform. Operators standing on the platform can pour chemicals smoothly into the tank, making the process much easier and safer.

3. Key Component Upgrades

Beyond the structural innovation of the platform, Xinhai's three-layer desorption electrolysis system also upgrades critical components that previously caused failures and downtime. These improvements significantly enhance system stability and production efficiency.

Electromagnetic Heater Replacing Traditional Electric Heaters: Conventional electric heaters often fail under long-term high-temperature and high-pressure conditions. They may leak or break, leading to frequent maintenance, higher costs, and production interruptions. Xinhai replaces these with electromagnetic heaters.

★ High efficiency and energy saving: Converts electricity directly into heat with efficiency above 90%. This reduces energy loss and saves significant operating costs over time.

★ Fast heating and precise control: Quickly raises temperature and maintains stable heat, ensuring the desorption process always runs under optimal conditions. This improves gold recovery efficiency and quality.

★ Safe and durable: Uses non-contact induction heating, minimizing leakage risks. The ring-shaped cable structure does not generate heat itself and withstands up to 500℃. With a service life of 5–10 years, maintenance needs are minimal.

★ Desorption Liquid Tank: Xinhai removes the heating tubes. Combined with the high-performance electromagnetic heater, the tank still maintains the required temperature. This upgrade ensures stable operation and reduces downtime caused by failures.

Xinhai's three-layer desorption electrolysis system replaces the conventional horizontal electrolytic cell with a vertical design. This upgrade improves space utilization, boosts efficiency, and enhances environmental performance.

✦ Save floor space and reduce construction costs: The vertical structure requires much less horizontal space. No drainage pit is needed, cutting civil engineering costs and shortening construction time.

✦ Increase electrowinning efficiency and recovery rate: The design allows electrolytic solution to distribute evenly between electrode plates, improving efficiency. Insulation between the tank and plates prevents precious metals from plating on the tank. A dedicated settling zone and discharge pipe reduce metal loss caused by slurry overflow.

✦ Lower power consumption and O&M costs: The vertical design reduces short-circuiting between plates, lowering energy consumption. Its compact structure makes operation, cleaning, and maintenance much easier, reducing labor and costs.

✦ Flexible and eco-friendly: Adaptable to different production requirements and suitable for various metals. It reduces reagent consumption during electrowinning, minimizing environmental impact.

The three-layer desorption electrolysis system has been successfully applied in real projects:

May 15, 2025 – Gold mine project in Henan, China: The system delivered stable performance. The three-layer platform and electromagnetic heater greatly improved production efficiency and lowered maintenance costs.

June 11, 2025 – Gold mine project in Gansu, China: Xinhai upgraded the electrolytic cell from horizontal to vertical. This saved significant space and civil construction costs while boosting recovery rate and efficiency.

From improving operational convenience to innovating key components and upgrading electrolytic cell design, every feature of Xinhai's three-layer desorption electrolysis system stems from a deep understanding of client needs. Every improvement aims to solve real production challenges. We are committed to global gold mining with advanced technology, high-quality equipment, and comprehensive services. Feel free to contact us!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.