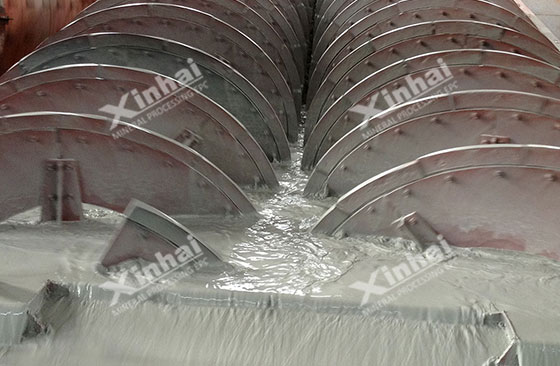

The spiral classifier is one of the important mineral processing equipment, whose working principle is to classify the materials by using the difference in the settling speed of solid particles in the liquid. The classifying effect of the spiral classifier will directly affect the content of the qualified product in the returned sand, thus affecting the grinding efficiency of the grinding mill.

In the classifying process, the factors that affect the classifying effect of the spiral classifier mainly include the following three aspects: the feeding of the spiral classifier, the structure of the spiral classifier and the operation mode of the spiral classifier. Below, we will specifically analyze how these three factors affect the classifying effect of spiral classifier.

There are mainly two factors that affect the classifying effect of the spiral classifier in the aspect of feeding, one is the mud content of feeding, another is the composition of particle size.

The larger mud content or the finer particle sizes in the feed are, the stronger slurry viscosity is, and the slower settling speed of ore particles in the slurry will be, thus the particle size of overflow products is coarse.

In this case, in order to obtain the required overflow fineness, the supplementary water can be appropriately increased to reduce the pulp concentration. If the amount of mud in the feed is small or the slurry has been deslimed, the slurry concentration should be increased appropriately to reduce the number of fine particles in the returned sand.

There are three main factors that affect the classifying efficiency of the spiral classifiers: the inclination angle of the groove, the height of the overflow dam and the rotation speed of the spiral.

The inclination angle of the groove affects the settling area of the classifier. But because the groove of the spiral classifier is fixed after the installation, the inclination angle of the groove should be adjusted to an appropriate angle. The installation angle of classifier equipment is generally between 16-18° is appropriate.

If the inclination angle is too large, the settlement area decreases, and the coarse material is easy to slide, the overflow particle size will be coarser, but the fine material in the returned sand will decrease accordingly. On the contrary, if the inclination angle is too small, the settlement area is large and the overflow particle size is fine, so the fine material in the returned sand will increase. Therefore, the inclination angle should be determined comprehensively according to the nature of materials, classifying fineness and other factors.

The common spiral classifiers mainly include spiral classifier and submerged spiral classifier. The spiral classifier is suitable for the classification of the coarse particle, and the particle size of classifying overflow is generally larger than 0.15mm. The submerged spiral classifier is suitable for the classification of fine particle, and the particle size of classifying overflow is generally less than 0.15mm. The common feature of both is that the height of overflow dam will affect the subsidence area. When the overflow dam is increased, the subsidence area is increased, the volume of the classifier is increased, but the overflow particle size is decreased. In general, the height of overflow dam is rarely changed once it is adjusted at the beginning of production. For spiral classifiers, the height range of overflow dam is usually controlled in the range of 400-800mm, while the height range of overflow dam is generally between 930-2000mm for the submerged spiral classifiers.

In addition, the rotating speed of the spiral will directly affect the agitation degree of the liquid surface and the capacity of conveying sand return. In the production, the overflow fineness and the productivity of sand return must meet the requirements. The faster the rotating speed is, the higher the capacity of returning sand is, but the increasing agitation effect will make the coarse particle sizes in the overflow increase. In general, the rotating speed of the spiral should be controlled within the range of 1.5-10r/min.

The operation mode of the spiral classifier mainly refers to the pulp concentration and the uniformity of ore feeding.

The pulp concentration is an important regulating factor, which has a great influence on the overflow fineness of spiral classifiers in actual production. Decreasing the pulp concentration, the overflow particle size becomes smaller, and the concentration increases, the overflow particle size also becomes coarser. Therefore, keeping a certain overflow particle size under an appropriate concentration can obtain the ideal production index. The suitable concentration of critical separation size can be determined by the mineral processing test.

The feeding amount of the spiral classifier should keep even and stable, otherwise, it is easy to cause the unstable classifying concentration. The classifying fineness fluctuates frequently, which can affect the production index of the next operation.

To sum up, the classifying effect of the spiral classifier involves many aspects, including the feeding of the spiral classifier, the structure of the spiral classifier and the operation mode of the spiral classifier. The mineral processing equipment technical experts suggest: first, please choose the formal mineral processing equipment manufacturers to buy the spiral classifiers, which can ensure the quality of equipment; In addition, in the daily production, the spiral classifier operators must pay more attention to the running state of the spiral classifier, take appropriate measures after analyzing the abnormal situation for ensuring the smooth operation of the spiral classifiers and obtaining the good classifying effect.

1. Vietnam 800tpd graphite ore dressing project

2. Morocco 500tpd silver ore dressing project

3. Russia 500tpd gold ore dressing project

4. Sudan 240tpd gold ore dressing project

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.