Chaihulanzi 100tpd gold processing project was designed by Beijing Central Engineering Institute for Non-ferrous Metallurgical Industry in 1984, then put into production in 1986.

1. Ore properties: The mineral belonged to the medium temperature hydrothermal filling gold-bearing quartz vein-type deposit. The ore was sericite altered rock sulfide-barren gold-bearing quartz vein with deep oxidized and more mud. The main metallic minerals were limonite, followed by pyrite, hematite and natural gold. The gangue minerals were mainly quartz, followed by feldspar, chlorite, mica and calcite.

Natural gold associated with gangue minerals. Gold dissemination size was fine and uneven, and the general particle size was 0.037 mm. Mineral density was 2.65 t /㎥.

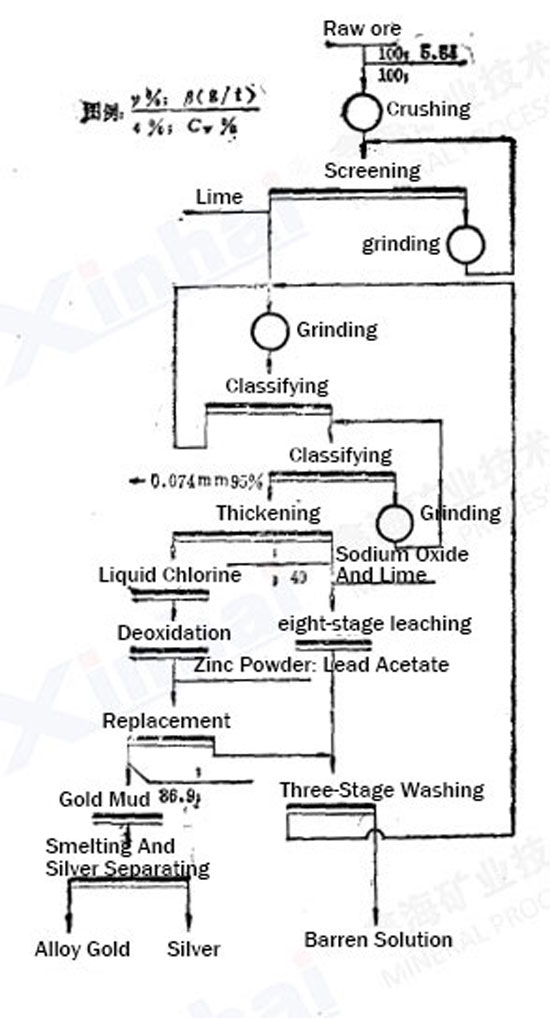

2. Process: Xinhai decided to adopt direct cyanidation, countercurrent washing and zinc powder replacement process. The final product was alloy gold and silver, as follows.

Ore cyanide is commonly known as all-slime cyanidation, which is seldom used in Chinese gold processing plant due to ore properties. At present, this process has been used in some gold plants in Tuanjiegou, Chiweigou and Chaihulanzi. However, this process occupies a leading position in foreign gold processing plants. All-slime cyanidation process is more suitable to deal with refractory oxidized ore. The leaching equipment used in this plant adopted a new type of axial-flow energy saving agitation tank with less energy consumption and higher efficiency.

Table 14.11-9 Process Indexes

| Item | Unit | Index | Note |

| Ore Grade | g/t | 5.64 | trial production index |

| Leaching Rate | % | 92.39 | |

| Washing Rate | % | 94.06 | |

| Replacement Rate | % | 94.79 (barren solution returns to leaching) | |

| Cyanide Recovery Rate | % | 86.90 |

Table14.11-10 Unit Consumption Index

| Name | Water | Electricity | Steel Ball | Sodium Cyanide | Flocculant | Zinc Powder | Lead Acetate | Liquid Chlorine |

| Unit | ㎥/t | kW·h/t | kg/t | kg/t | kg/t | kg/t | kg/t | kg/t |

| Quantity | 5 | 1.28 | 0.051 | 0.31 | 0.038 | 1.28 |

Table14.11-11 Main Equipment

| No | Name and Specification | Quantity |

| 1 | 250×400 Jaw Crusher | 1 |

| 2 | SZZz900×1800 Vibrating Screen | 1 |

| 3 | PEX150×750 Jaw Crusher | 1 |

| 4 | MQY1500×3000 Overflow Ball Mill | 1 |

| 5 | FLG-1200 Single-spiral Classifier | 1 |

| 6 | φ150 Hydrocyclone | 4 |

| 7 | TNZ-15 Thickener | 1 |

| 8 | φ3000×5000 Axial-flow Agitation Tank | 8 |

| 9 | φ9000 Thickener | 2 |

| 10 | 2100×2100×22 Blade Purification Tank | 2 |

| 11 | φ1500×3600 Deoxygenation Tower | 1 |

| 12 | BMS20/635-25 Press Filter | 2 |

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.