Lead and zinc in lead-zinc ores often appear in ore bodies with similar chemical characteristics and occurrence methods, usually with the presence of lead sulfide minerals (such as galena PbS) and zinc sulfide minerals (such as sphalerite ZnS) feature. The metals lead and zinc are used in various industries, for example lead is commonly used in batteries, construction materials and ammunition manufacturing, while zinc is used in galvanized steel, alloy manufacturing and as a corrosion resistant coating. Therefore, lead-zinc ore is an important source of these metals.

The beneficiation process for extraction of lead zinc ore usually includes processes such as crushing, grinding, flotation and dehydration. The resulting concentrate is further processed to obtain pure lead and zinc products through processes such as smelting and refining. Because the specific geology and mineral composition of each deposit may vary, so will the beneficiation methods used for extraction of lead zinc minerals. This article will introduce several lead-zinc ore beneficiation methods and the equipment used.

For the processing of lead-zinc ore, a variety of beneficiation methods can be used to separate and concentrate valuable lead and zinc minerals from the ore. Some common beneficiation methods for lead-zinc ore extraction include:

1. Lead-zinc ore flotation method:

Flotation is a widely used method for the selective separation of lead and zinc minerals. It relies on differences in the surface properties of minerals. By adding chemicals, buoyant bubbles are formed on the surface of the slurry, so that valuable minerals are attached to the bubbles and brought to the bubbles layer, while waste rock minerals sink.

2. Gravity separation of lead-zinc ore:

Using gravity separation methods, such as jig, shaking table and spiral chute, can separate according to the density difference of lead and zinc minerals. This method is very effective for coarse-grained ores or where there are significant density differences between minerals.

3. Magnetic separation of lead-zinc ore:

Magnetic separation is used to separate magnetic minerals from non-magnetic waste rock minerals. If there are magnetic minerals in the lead-zinc ore, they can be recovered by magnetic separation techniques such as high-intensity magnetic separation or low-intensity magnetic separation.

4. Separation of heavy media for lead-zinc ore:

Dense media separation suspends lead-zinc ore in a heavy medium, such as a suspension of ferrosilicate or magnetite. The difference in density between valuable minerals and waste rock allows their separation by sinking and floating.

5. Gravity or magnetic separation after flotation:

In some cases, flotation followed by gravity or magnetic separation can be combined to further increase separation efficiency. This method is particularly useful for complex lead-zinc ores with multiple minerals and fine particle size distributions.

The choice of a particular beneficiation method depends on the characteristics of the ore, including mineralogy, grade and cleavage size. According to the specific ore conditions, different methods can be combined to realize the separation and concentration of lead-zinc minerals.

During the beneficiation process of lead-zinc ore, various ore beneficiation equipment will be used to separate lead and zinc minerals. Some of the equipment commonly used in lead-zinc ore beneficiation include:

1. Crushing equipment: Crushing equipment is used to break large rocks into smaller, more manageable sizes. These devices are used to reduce the size of ore before further processing.

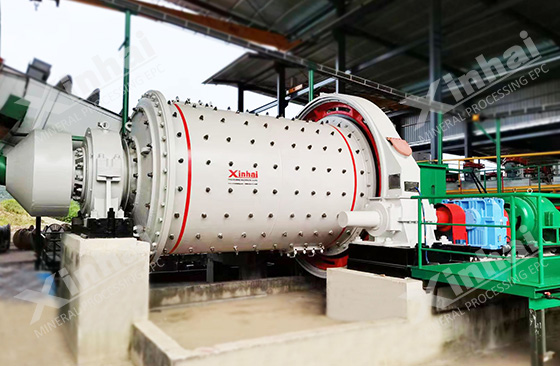

2. Grinding equipment: Grinding equipment, such as ball mill and rod mill, are used to grind ore into fine powder. The grinding process helps liberate valuable minerals from waste rock and prepares it for subsequent beneficiation steps.

3. Flotation equipment: Flotation equipment is the key equipment in the flotation process of lead-zinc ore, and is widely used in lead-zinc ore concentrators. These devices help separate valuable minerals from waste rock by agitating the slurry to create air bubbles.

4. Gravity separation equipment: Gravity separation equipment, such as jigs, spiral chutes and shakers, are used for gravity separation. They use density differences to separate heavy minerals, including lead and zinc minerals, from lighter waste rock.

5. Magnetic separation equipment: Magnetic separation equipment uses magnetism to separate magnetic minerals from non-magnetic waste rock minerals. If magnetic minerals are present in lead-zinc ore, magnetic separators can be used to recover them.

6. Concentration and filtration equipment: Concentration and filtration equipment, such as thickeners, filters and centrifuges, are used to remove water and concentrate valuable minerals after flotation or other beneficiation processes.

7. Smelting and refining equipment: Smelting and refining equipment, such as smelting furnaces and electrolytic cells, are used to process concentrated lead and zinc minerals into metal products.

The selection of specific equipment and processes depends on the characteristics of the ore, the expected results of the beneficiation process and the scale of operation. Different combinations of equipment can be used to achieve efficient lead-zinc ore processing and maximize the recovery of valuable minerals. Xinhai Mining recommends ore beneficiation testanalysis to optimize the beneficiation process for extraction of lead zinc ore. Xinhai Mining can provide you with one-stop service for lead-zinc ore beneficiation, including ore composition analysis, beneficiation scheme design, and complete equipment production manufacturing, equipment delivery, equipment installation and commissioning, welcome to leave a message for consultation.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.