Potassic feldspar is an important industrial ore, widely used in ceramics, glass, building materials, chemical industry, electronics, metallurgy and other industries. The development and utilization of potassium feldspar resources is of great significance to the development of the national economy. In the process of potassic feldspar beneficiation, iron removal is a necessary part. The existence of iron impurities will seriously affect the quality of potassium feldspar concentrate. The following will introduce the necessity of potassic feldspar iron removal and potassium feldspar iron removal methods.

When beneficiating potassium feldspar, iron removal is an important part of the process. The following will illustrate the necessity of potassium feldspar iron removal from 5 aspects.

Iron impurities in potassium feldspar can affect the quality and characteristics of the final product. Iron oxides or hydroxides can give potassium feldspar an undesirable color and reduce its commercial value. By removing iron impurities, the resulting potassium feldspar concentrate can be of higher purity and meet the required quality standards.

Iron impurities can give potassium feldspar a yellow or brown hue, which is undesirable in many applications. Removal of iron impurities helps to obtain potassium feldspar that is visually appealing and consistent in color, making it more suitable for applications in ceramics, glass and other industries.

Iron-bearing minerals in the ore can interfere with the beneficiation process, hampering the efficiency of subsequent processing steps. For example, iron minerals may compete with K-feldspar particles for collector attachment during flotation, resulting in lower K-feldspar recovery. By removing iron impurities, the overall efficiency of the beneficiation process can be improved and a higher purity potassium feldspar concentrate can be obtained.

Many end users of potassium feldspar have strict requirements on the iron content in their products. Industries such as ceramics, glass, and electronics generally require potassium feldspar to have as low an iron impurity as possible in order to achieve the desired performance and appearance. By removing iron impurities, potassium feldspar becomes more market-competitive and can meet the specific needs of various industries.

Iron impurities in the ore will cause damage to processing equipment such as crushing equipment, grinding equipment, and magnetic separation equipment. These impurities increase wear and tear on equipment, resulting in higher maintenance costs and shortened equipment life. Removing iron impurities helps protect processing equipment and maintain its operating efficiency.

The iron removal process in the beneficiation process of potassium feldspar usually includes the following steps:

1. Crushing and grinding: the potassium feldspar ore is sent to the crusher to be crushed into small particles and ground into fine powder. This step is designed to increase the surface area of the ore for efficient iron removal in subsequent processing stages.

2. Magnetic separation: Magnetic separation is often used to remove iron-containing minerals from potassium feldspar ore. In this process, the finely ground ore passes through a magnetic separator, which uses magnetism to separate magnetic minerals, including iron-bearing minerals, from the non-magnetic fraction. The magnetic separation process helps to remove iron impurities and improve the quality of the final potassium feldspar concentrate.

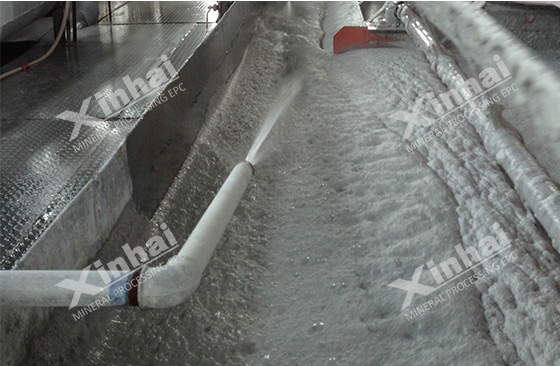

3. Froth flotation: Froth flotation is one of the commonly used iron removal methods in potassium feldspar beneficiation. In this process, frothers, specific collectors and conditioners are added to the finely ground pulp. The foaming agent forms foam on the surface of the slurry, while the collecting agent selectively attaches to the iron-bearing minerals, making them hydrophobic and floating to the liquid surface. The froth of iron-bearing minerals is then removed, leaving a pure concentrate of potassium feldspar.

4. Gravity separation: When the density of iron-containing minerals is higher than that of potassium feldspar, gravity separation technology can be used to remove iron. In gravity sorting, ore is scoured by water currents, causing denser iron-bearing minerals to settle at the bottom, while lighter-density potassium feldspar particles float to the top. This allows iron impurities to be separated from the potassium feldspar concentrate.

5. Dehydration and drying: After the iron removal process, the potassium feldspar concentrate is dehydrated to remove excess water, and then dried to reach the specified moisture content. Dehydration and drying help to obtain the final product with the desired moisture content and suitable for subsequent handling or transportation.

The above are the necessary and iron removal steps for potassic feldspar ore. It should be noted that the iron removal process of potassium feldspar ore may vary due to ore characteristics, impurity content and final product quality requirements. Therefore, Xinhai Mining suggested to conduct potassic feldspar ore beneficiation test and customize potassium feldspar beneficiation process to achieve efficient iron removal process.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.