solutions

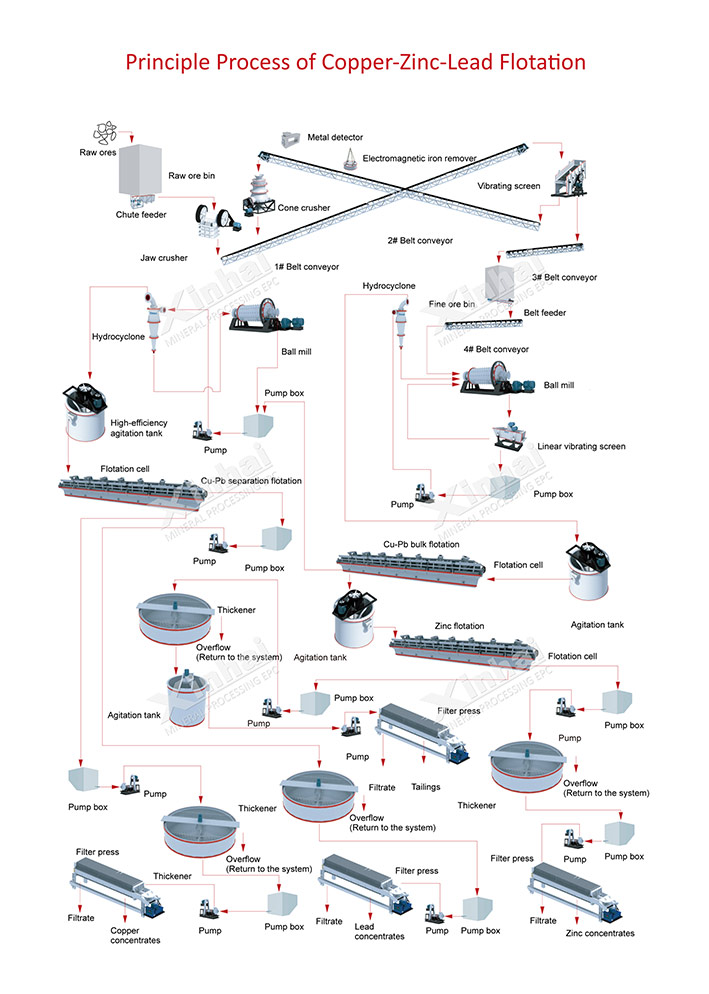

[Introduction]: Adopting mixed flotation-concentrate regrinding process can reduce the grinding cost, and be easy to manage. Application of new non-toxic flotation reagents is efficient and environmental protection.

[Improvement]: Mixed flotation-concentrate regrinding process is applied for Cu-Pb-Zn sulfide ore.

Cu-Pb mixed concentrate regrinding process saves the grinding cost without finely grinding all raw ore, and it makes further monomer dissociation to create favorable conditions for the separation of copper and lead.

In rough flotation, the reagent is carried out strictly to control the reagent amount, realizing early recovery as possible. Reduce multiple recycling and valueless loss. Make the best of foam secondary enrichment, and wash the concentrate foam to reduce the impurities in foams according to suitable water adding.

In flotation stage, the copper-lead mixed concentrates should be priority separated. After regrinding, the lead concentrates and copper concentrates are separated by flotation and respectively dewatering.

After copper-lead mixed flotation and mixing the slurry, zinc concentrates are separated by flotation from tailings. After dewatering, the zinc concentrate product is required.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.