solutions

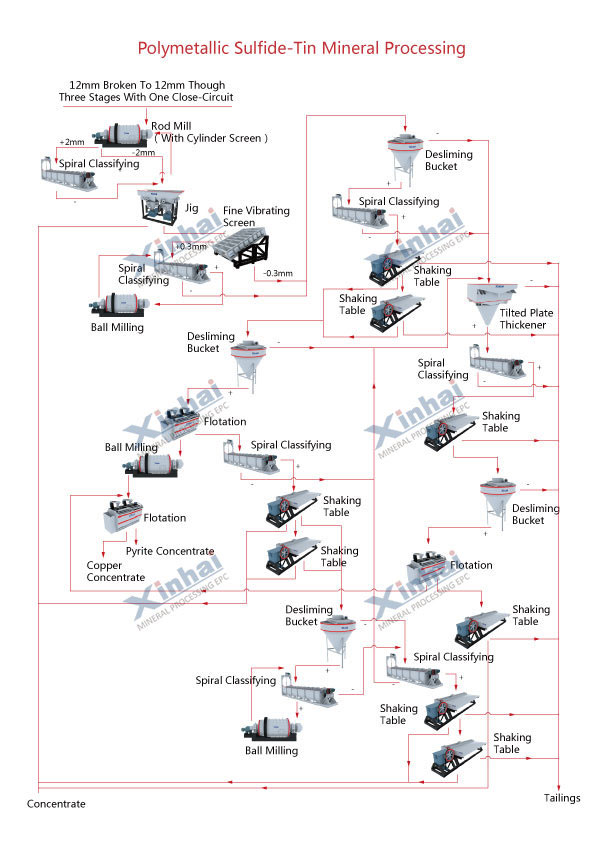

[Introduction]: The density of tin ore is larger than the paragenetic mineral, so the mining process of tin ore is gravity separation. However, all kinds of iron oxides exist in those ore, like magnetite, hematite, etc., which cannot be well separated by using gravity or flotation separation. Herein, magnetic separation and flotation separation will be used.

[Improvement]: Gravity separation is the traditional method for tungsten, tin and gold, especially placer gold and placer tin. It is also common in the application of rare metal placer ores(niobium, tantalum, titanium, zirconium and so on). It is also used for weak magnetic iron ore, manganese ore and chrome ore.

Crush the raw ore to 20mm, then screen it into two particle sizes, (20mm~4mm) and (4mm~0mm).

Put the 20~4mm ore into heavy medium cyclone to be selected. Then the ore will enter into the rod mill. After that, it will be preselected in jig. The tailings over 2mm will be abandoned, and the ore below 2mm will be put into shaking table.

The concentration from jig and shaking board will be separately selected by bulk flotation. The tailings will enter the shaking board to get qualified tin concentrates.

After the bulk flotation, the concentrate will be fine grinded, then will be do the flotation separation of lead zinc ore. After that Lead antimony concentrates and zinc concentrates will be produced.

The tin pulp enter into Φ300mm hydrocyclone, then overflow to Φ125mm and Φ75mm hydrocyclone group to remove the fine mud. The sand setting will enter into the process of thickening, desulphurization by flotation, and then cassiterite flotation.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.