solutions

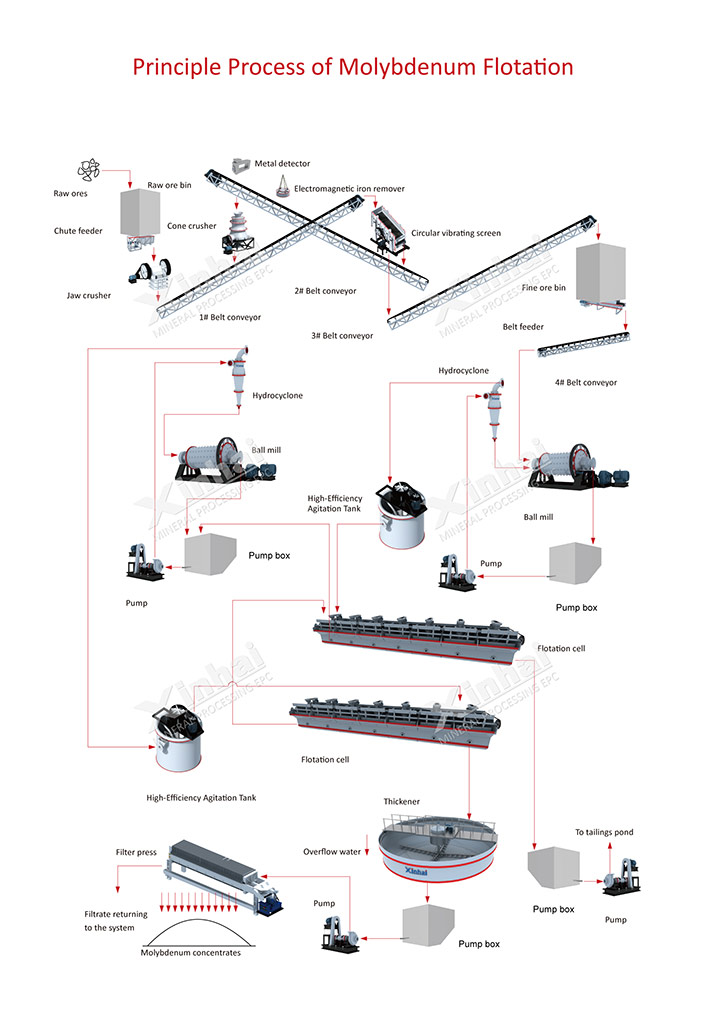

[Introduction]: Coarse concentrate regrinding and re-separating improves the concentrate index; Determine concentrate regrinding and re-separating process according to the ore properties; To reduce energy consumption by 30%, recovery rate is increased by more than 10%.

[Improvement]: Molybdenum dressing production line can be used for single or refractory molybdenum with complex properties, close sulfide minerals symbiosis and fine particle distribution

Mixed roughing after the coarse grinding, then regrinding the coarse concentrate and cleaning; the small quantity of regrinding crude concentrate makes monomer dissociation and save energy consumption while obtaining high grade concentrate and high recovery rate.

Strict implementation of agent system in roughing and control agent dosage to reduce the loss of many cycles; make full use of the twice enrichment of bubble; washing concentrate foam to reduce the impurity in foam flotation.

Stage-processing is appiled to recover valuable minerals in different particle sizes as possible to improve the concentrate indexes.

Xinhai can provide the whole set of equipment for the production line, guaranteeing the fitness of equipment and processing technology.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.