products

[Introduction]: A feeder with periodic reciprocating motion for fine particles

[Capacity]: 4.5~25t/h

[Improvement]: Adopt the worm gear reducer, compact structure, and equipped with reliable sealing device.

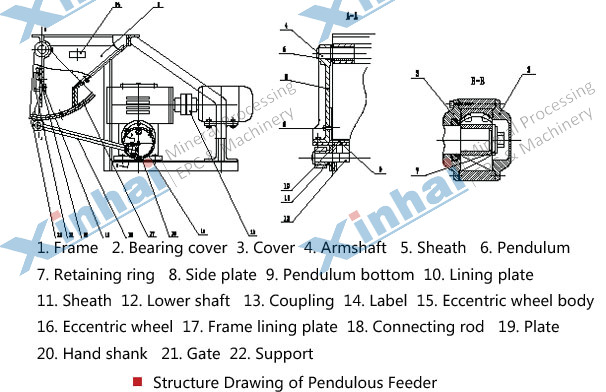

The machine is installed beneath the discharging opening of ore bin. Minerals fall in the ore feeding box from ore bin. When it works, via coupler, electric motor drive turbine reducer to operate; the pendulum plate of chute begin the reciprocal movement through eccentric wheel on the output shaft of turbine reducer. So, the mineral feeding process is finished. The mineral feeding quantity can be controlled by adjusting eccentric wheel or regulating the revolving speed of motor.

| Model | Inlet (LXW) (mm) | Outlet (LXW) (mm) | Stroke of Eccentric Wheel (mm) | Frequency (n/min) | Max. Feed Size (mm) | Feed Capacity (t/h) | Motor Model | Motor Power (kW) | Rotating Speed of Motor (r/min) | Weight (kg) |

| BG250X250 | 250X250 | 250 X (30~125) | 0~90 | 46 | 25 | 4.5 | Y80L-4 | 0.55 | 1390 | 130 |

| BG300X300 | 300 X300 | 300 X (30~125) | 46 | 30 | 6.5 | Y802-4 | 0.75 | 1390 | 272 | |

| BG400X400 | 400 X400 | 400 X (50~130) | 0~170 | 45.5 | 35 | 12 | Y90S-4 | 1.1 | 1410 | 558 |

| BG600X600 | 600 X600 | 600 X (50~150) | 0 ~157 | 48 | 50 | 40 ~80 | Y100L-4 | 1.5 | 940 | 613 |

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.