Scheelite deposits are mostly skarn-type, with finer grains, often associated or symbiotic with a variety of sulfide minerals such as molybdenum and bismuth. Scheelite can be divided into two types according to the type of ore: scheelite-quartz (or silicate mineral) type and scheelite-calcite-fluorite type. The former is easier to recover, while the latter is more difficult to beneficiate because of its more complex ore properties. This is mainly because the floatability of scheelite and its symbiotic calcium-containing gangue minerals is similar, and tungsten ore is brittle. Therefore, flotation is often used as the main method for ore dressing.

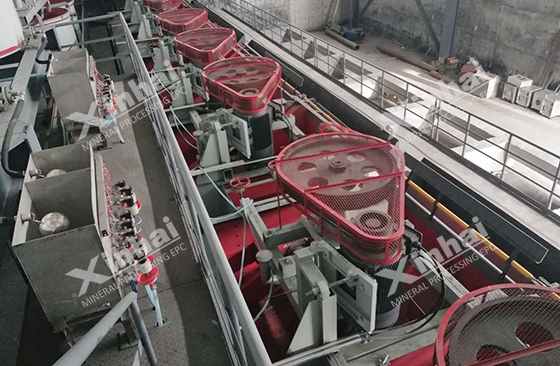

The flotation of scheelite is roughly divided into two parts: roughing and concentrating. The roughing stage is mainly to maximize the recovery rate of scheelite, while concentrating is the key to obtaining qualified tungsten concentrate. Therefore, in order to obtain qualified tungsten concentrate, the roughing and concentrating processes require strict process flow, and often multiple concentrating processes are required to achieve the desired effect.

The roughing of scheelite is to recover scheelite to the maximum extent. In the roughing stage, lime flotation and sodium carbonate methods are commonly used. Although both are pH adjusters, their principles are different.

Sodium carbonate method: Na2CO3 can be used as a pH adjuster and a dispersant for slurry. It can also precipitate metal ions in the slurry that have an adverse effect on flotation, thereby improving the flotation index of tungsten ore.

Lime method: The role of lime is mainly to use the adsorption of Ca2+ on the surface of gangue minerals to change the potential of the surface of gangue minerals, and then add inhibitors such as water glass to inhibit the gangue minerals, thereby achieving the separation of tungsten ore and gangue minerals.

The key to scheelite concentration is to separate tungsten ore from gangue minerals to the greatest extent and improve the grade of tungsten concentrate. The main concentrating processes for scheelite after roughing are heating method and normal temperature method.

Heating flotation of scheelite concentrate: mostly suitable for mines with high calcium mineral content and low tungsten content. The method mainly refers to the concentration of the concentrate from roughing, the concentration of the concentrated ore pulp is between 60%-70%, and then a large amount of water glass is added to it, stirred at high temperature, and finally the ore pulp is diluted and floated at room temperature. In this process, different mineral surfaces have different collector film decomposition speeds, so the inhibition of minerals is also different, thereby achieving mineral separation. However, since this method requires heating, its working environment temperature is high, the environment is relatively poor, the cost is also high, and its process is relatively complicated and difficult to operate.

Room temperature flotation of scheelite concentrate: commonly used in quartz vein mine flotation, often with alkaline medium (sodium hydroxide, sodium carbonate) to adjust the pulp, metal salt as activator, water glass as depressant, and mixed collector to complete flotation; in addition, water glass can be used in combination with macromolecular organic depressants such as baked glue and tannin as combined depressors, and mixed collectors to achieve flotation.

The above is an introduction to the two methods of roughing and concentrating in scheelite. In actual ore dressing plants, due to the complex ore properties of scheelite, the processing conditions of each process are different. Therefore, it is recommended to conduct ore dressing tests, and design suitable scheelite ore dressing process plans through experimental analysis to improve its ore dressing efficiency.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.