At present, the grade of raw tungsten ore in the world is decreasing year by year. There are less and less easy-to-mining wolframite, while refractory scheelite and wolframite-scheelite intergrowth ore gradually occupy the main position. Therefore, Xinhai Mining strengthens the research on tungsten extraction process, and customizes the ideal tungsten extraction equipment according to the different types of tungsten ore, strives to improve the tungsten extraction efficiency and reduce the production costs.

Key: Obtain the tungsten concentrate with high recovery and high quality

√ In coarse grinding stage, Xinhai adds xanthophyll collector to float various sulfides first;

√ In the gravity separation stage, Xinhai adopts the shaking table to get some or all qualified tungsten concentrate.

√ For the tailings after the gravity separation stage, Xinhai floats the scheelite with oleic acid collector, and get 10%-25% gross concentrate, which is sent to wet metallurgical processing.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

Key: Roughing stage and concentrating stage

Roughing stage---Maximize the grade of the coarse concentrate;

Concentrating stage---Separate the calcium gangue minerals from scheelite to obtain the qualified tungsten concentrate.

√ Xinhai uses the sodium sulfide, cyanide and chromate to inhibit the associated sulfide minerals, and adopts the sodium silicate, tannin, sodium polyphosphate, chromate to inhibit the gangue minerals. Then, using the sodium silicate or sodium carbonate to adjust the pH value of the pulp to 9.5-10, and 11-12 for cleaning stage.

√ “Lime – flotation” process. Xinhai mixes the pulp with the lime, then adds the sodium carbonate and sodium silicate, finally collects by the oleic acid and naphthenic acid.

√ Xinhai adopts sodium silicate heating method, which means adding a certain amount of sodium silicate to low-grade coarse concentrate, heating up, cooking, stirring, dehydration and slurry mixing, then concentrating repeatedly. Finally, the high-grade tungsten concentrate can be obtained.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

Key: Using the jig to recover early, and shaking table to discard tailings

√ Roughing: In the first stage of fine-grained roughing, Xinhai adopts jig to separate, then directly enters into the concentrating stage.

√ Gravity separation: Xinhai adopts multi-stage jigging, multi-stage shaking table, middling regrinding and gravity separation process.

That is, the jigging gross sand is produced when the qualified ore is sent to multi-stage jigging after the vibrating screen. The coarse-grained jig tailings are sent to grinding mill for re-grinding, and the fine-grained jig tailings enter into multi-stage shaking table after the classifier, then the shaking table gross sand is produced. The shaking table tailings are sent to the tailings pond, and the middlings are returned for regrinding and re-separating, and the gross sand of jig and shaking table is sent to concentrating stage.

√ Concentrating: Xinhai adopts flotation-gravity separation combined process or flotation-gravity separation-magnetic separation combined process, and recovers the associated elements in the concentrating stage.

Through the coarse and fine-grained table flotation (flotation -shaking table combined method) and flotation to remove the sulphide ore, the sulphide ore of table flotation and flotation merges into the sulfide ore flotation separation. And the wolframite after table flotation and flotation becomes the wolframite concentrate by the gravity separation process. If there are scheelite and cassiterite in the wolframite concentrate, gravity separation-flotation or gravity separation-flotation-magnetic separation combined process can be adopted to separate wolframite concentrate, scheelite concentrate and tin concentrate.

√ Fine sludge treatment: Xinhai usually carries out desulfurization first, and then adopts gravity separation, flotation, magnetic separation, electric separation or combined process to recycle the tungsten ore according to the properties of fine sludge, and utilize the associated metal minerals at the same time.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

For the extraction of tungsten from wolframite-scheelite intergrowth ore, especially the fine-grained wolframite-scheelite intergrowth polymetallic ore, Xinhai usually adopts the bulk flotation process.

Key:Separate the scheelite and wolframite from the symbiotic polymetallic ores

√ Bulk flotation of sulfide ore - bulk flotation of wolframite and scheelite - heating and separation of scheelite - strong magnetic separation of scheelite tailings - gravity separation of wolframite;

√ Bulk flotation of sulfide ore - strong magnetic separation to separate wolframite and scheelite - scheelite flotation - wolframite flotation.

Spiral Classifier

Magnetic Separator

SF Flotation Cell

BF Flotation Cell

If you have any questions, please contact us by the following ways, and we will provide you with better help!

Ore property: uneven distribution of mineral dissemination particle sizes, and serious mineral mud.

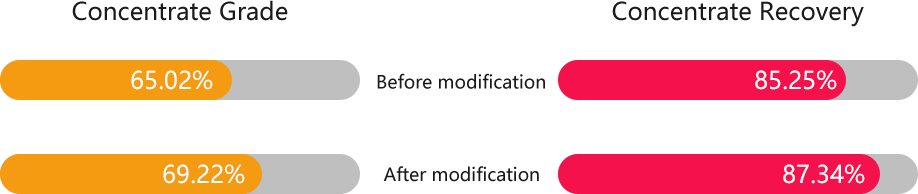

Before: The original plant adopted crushing pre-separation-gravity separation-concentrating process, which resulted in the loss of a large amount of fine-grained tungsten minerals, high mineral processing cost and poor mineral processing indexes.

After: After making the careful research on the ore properties and processing technology, Xinhai decided to optimize the wolframite process, add fine slime processing technology, and finally get the better mineral processing indexes.

Project result: Comparison between before and after:

After the modification, the recovery of fine-grained wolframite was strengthened obviously, and the influence of fine slime on the wolframite separation was reduced, which obviously improved the recovery indexes and the economic benefit of the plant.

If you have any questions, please contact us by the following ways, and we will provide you with better help!

Xinhai has make class B design qualification, and set up mine design institute and mineral processing research institute. More than 200 professionals provide the technical support service for 70 kinds of ore.

Depending on its professional mineral processing EPC+M+O service, Xinhai has got the EU certification, and ISO9001:2015 quality management system certification, who is classified as the assured brand with advanced products and standard quality!

Xinhai has multiple patents technologies, more than 500 mineral processing plants spread among China, Southeast Asia, South America, Africa, Iran, Russia, Mongolia, North Korea and other places, and Xinhai has established multiple overseas offices around the world.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.