From the start of civil construction of the Bikita 2 million TPA spodumene processing project in Zimbabwe in July 2022 to the official completion and production of the project in July 2023, it took a total of 364 days. This project has become a model for Chinese-funded overseas mining projects! Xinhai Mining provided EPC+M+O service for this project, including mineral processing design and research, equipment manufacturing and procurement, processing plant civil engineering and installation, mine construction management, and mine operations!

The Bikita 2 million TPA spodumene processing project in Zimbabwe adopts an overall intelligent dressing plant solution and an intelligent control system for the entire mineral processing process to achieve all-round optimization and improvement of management level, production quality, production efficiency, production cost, etc.!

Xinhai Mining has strong capabilities in R&D, design, processing and manufacturing of automated products. The Zimbabwe Bikita 2 million TPA spodumene processing project team customized automated equipment for the project, including cone crushers, ball mills, cyclones, and flotation machines, automatic lubricating machine, automatic dosing machine, automatic ball adding machine, automatic sampling machine, thickener, filter press, etc., to achieve the deep integration of "intelligent +" and equipment manufacturing. The intelligent equipment can improve the operating capacity and efficiency of each process in the dressing plant, reduce production costs and labor intensity, and improve the working environment.

Crusher

Xinhai Mining Cone Crusher can monitor the operation of the equipment in real time (operating status, current, frequency, material level in the cavity, hydraulic station pressure, temperature, alarm, etc.), and the personnel on duty can remotely adjust the crusher operating frequency according to the material level, and perform the equipment starts and stops.

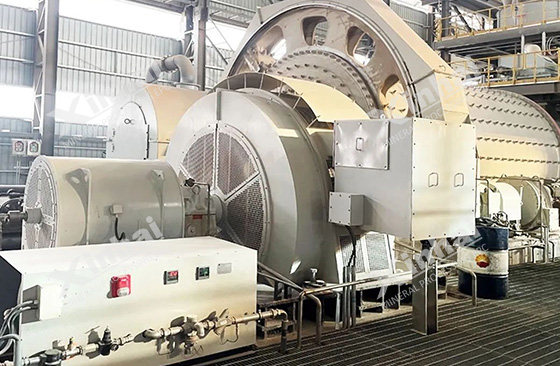

Ball mill

Xinhai Mining ball mill has the control, protection and interlocking functions of lubrication station, jet lubrication station (including air compressor system), and slow drive system; it can detect temperature signals, oil pressure signals, oil flow signals, and vibration measurement signals to achieve intelligent real time monitoring.

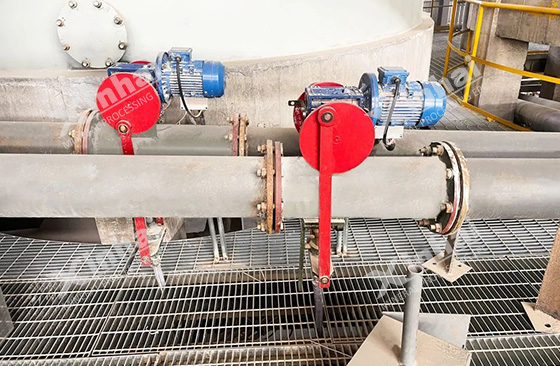

Cyclone

Xinhai Mining Cyclone Group installs pneumatic valves in the inlet pipes of each cyclone to replace manual operation. The valve switch detection can be displayed on the touch screen; at the same time, the standby switching of the cyclone can also be operated on the touch screen to improve the level of safe production.

Flotation machine

Xinhai Mining is equipped with a flotation level control device for each flotation unit, which can set the slurry level (or foam layer thickness) of the flotation tank according to the process; when the slurry volume fluctuates, the slurry level of the flotation tank ( When the foam layer thickness) changes, the automatic control device can automatically adjust to stabilize the slurry level.

Automatic lubrication dispenser

Xinhai Mining's automatic lubrication oil dispenser can supply oil at a fixed time, at a fixed point, and in a quantitative manner, saving grease; refueling without stopping the machine reduces workload and reduces the occurrence of safety accidents, making it safe and efficient.

Automatic dosing machine

Xinhai Mining Automatic Dosing Machine can set the dosing amount, continue to add steadily, and ensure stable flow.

Automatic ball adding machine

Xinhai Mining Automatic Ball Adding Machine can add steel balls quantitatively and evenly; it optimizes the steel ball adding mechanism to improve the grinding effect.

Automatic sampling machine

Xinhai Mining Automatic Sampling Machine can set the sampling machine running speed and sampling time interval. Manual sampling requires climbing the pump box and sampling at the mouth of the slurry outlet pipe. After the automatic sampler is put into use, the number of personnel and labor intensity of the position are effectively reduced, and the production efficiency is further improved.

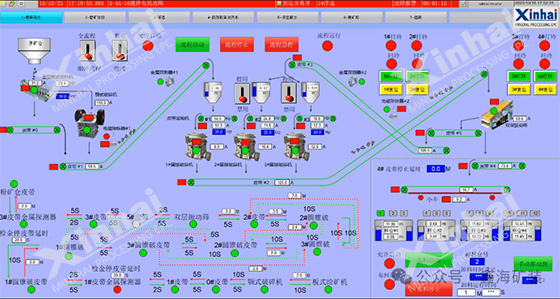

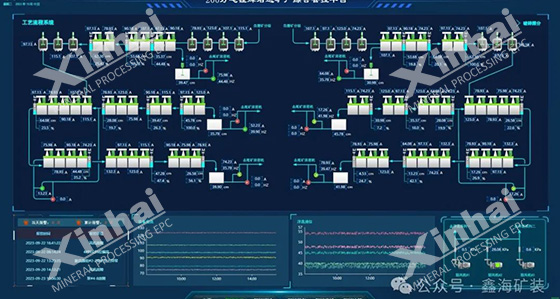

Xinhai Mining carried out coordinated optimization and control of all aspects of the mineral processing process of the Bikita 2 million TPA spodumene processing project in Zimbabwe, integrating the crushing and screening automation system, the grinding and classification automation system, the flotation automation system, the pharmaceutical preparation automation system, and the dehydration automation system. The system, concentrate warehouse automation system and the Internet of Things cloud platform are connected to realize the automation of the entire process of the mineral processing plant.

Crushing and screening automation system

Crushing and screening adopts a three-stage, one-closed-circuit process. The automated management and control system can realize functions such as one-click chain start and stop, fault chain control, equipment safety protection, and cone crushing and feeding optimization control for the entire process. The software platform monitors the real-time operating status, signal curves, fault alarms and warehousing information of each equipment in the process, which is easy to operate and highly intelligent.

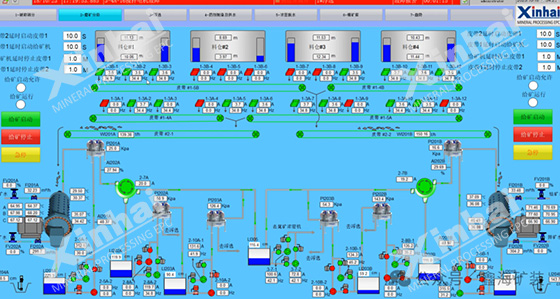

Grinding and classifying automation system

The grinding and classifying process includes a closed-loop ball mill and cyclone, magnetic separation and desliming processes. The automated management and control system implements ore volume, water volume, pressure, concentration, particle size, liquid level and circulating load on the basis of ensuring the stable operation of the equipment. Automatic control of other indicators, the collected data information is displayed in the form of trend curves and reports, making it convenient for operators to review and analyze.

Flotation automation system

The automated system effectively improves the flotation process indicators by intelligently adjusting the liquid level, aeration volume and dosage of the flotation tank. The flotation tank liquid level control system uses pneumatic and electric actuators, and each group of flotation tanks is controlled collaboratively to achieve good adjustment effects. The flotation automatic dosing machine adopts a digital dosing pump, which can accurately control and measure the dosage of each dosing point.

The video surveillance system designed by Xinhai Mining can cover all equipment, important entrances and exits, weighing rooms, new water return pools, etc. of the Bikita 2 million TPA spodumene project in Zimbabwe. The large-screen splicing system is used to display video surveillance images and process flow images, etc. It is set up in the control room to conduct centralized monitoring of the entire processing plant. The screen can be freely exchanged, with functions such as single-screen display, full-screen display, arbitrary segmentation, image capture, and network capture, making the operation flexible and changeable.

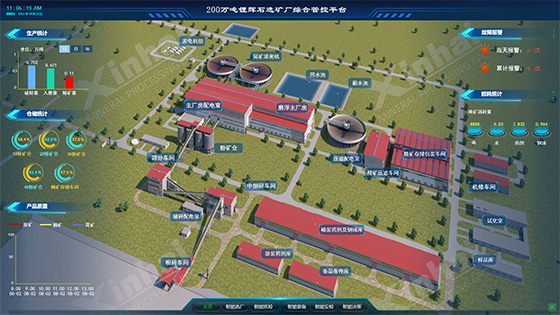

Xinhai Mining has built a smart mine management and control platform for the Bikita 2 million TPA spodumene project in Zimbabwe, which can realize all-mine data collection, transmission, integrated use, big data analysis and processing, etc., and control the company's personnel, equipment, materials, energy, logistics, etc. are intelligently managed and controlled to achieve smart models and goals of safe and efficient production and green mines.

In recent years, Xinhai Mining has continuously accelerated its research and development process, driven intelligent transformation with innovative technologies, and combined the automation, informatization, and intelligent professional technical services required for mine construction with Xinhai Mining EPC +M+O service integrate with each other to form an overall solution for smart mines to build a modern smart mine and promote the green and high-quality development of the mining industry!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.