Hydraulic cone crusher, as a widely used medium and fine crushing equipment, is favored by more and more users for its high efficiency, stability, and easy operation. It can not only easily handle various hard ores and rocks, but is also equipped with hydraulic adjustment, overload protection, and other intelligent functions, which greatly improves working efficiency and safety. Whether it is used in a large gravel plant, or metal mine crushing production line, a hydraulic cone crusher is competent. So, what is the working principle of a hydraulic cone crusher? What are the main advantages? What should be considered when choosing hydraulic crushers? Please read on, after reading this article you will get the answer.

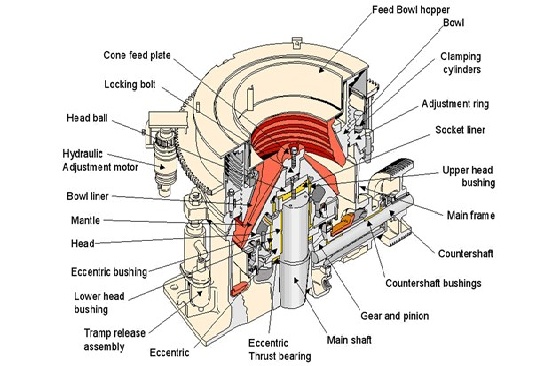

The hydraulic cone crusher system mainly consists of a frame, transmission device, hollow eccentric shaft, bowl-shaped bearing, crushing cone, spring, and a hydraulic station used for adjusting the discharge opening. During operation, the motor drives the eccentric sleeve to rotate through the horizontal shaft and bevel gears. Under the action of the rotating eccentric sleeve, the main shaft of the crushing cone performs an eccentric swinging motion, causing the crushing wall to approach or move away from the concave wall repeatedly. This motion achieves the extrusion, bending, and crushing of the ore. At the same time, the hydraulic system not only enables precise adjustment of the discharge opening but also features a rapid cavity clearing function, effectively ensuring stable product size, improved crushing efficiency, and safe and reliable operation of the equipment.

1. High Crushing Efficiency - Continuous rotation of the dynamic cone, large crushing ratio, high processing capacity;

2. Overload Protection - Double insurance of hydraulic and lubrication system ensures that the bearings of Hydro Cone Crusher are well lubricated when it is overloaded;

3. Improve Product Quality - A variety of crushing chamber types are available, by choosing the appropriate crushing chamber type and eccentric distance, to meet the production demand and realize high production capacity;

4. Easy Maintenance - Simplify the structure of the crusher, reduce the weight, all the maintenance and inspection can be completed in the crusher, maintenance is more convenient;

5. Low Operation Cost - The hydraulic adjustment of discharge opening can conveniently and timely adjust the discharge opening, so that the crusher machinery can be operated in the full feeding state, reducing the consumption of wearing parts and lowering the operation cost;

The materials that Hydraulic Crusher can process in the ore industry mainly include:

Metal ores: such as iron ore, copper ore, gold ore, lead-zinc ore, etc. It is suitable for crushing medium-hard to hard ores.

Hard rock: including granite, basalt, etc., for high intensity crushing operation.

Highly abrasive ores: such as pyroxene, etc. The equipment adopts wear-resistant materials to prolong service life.

Impurity-containing ores: with the hydraulic cavity clearing function, it effectively prevents clogging and ensures continuous and stable production.

1. Single Cylinder Hydraulic Cone Crusher (simple structure, flexible adjustment, suitable for small and medium-sized mines)

2. Multi-cylinder Hydraulic Cone Crusher (large capacity, suitable for large and medium-sized mines and aggregate plants)

3. Fully Hydraulic Cone Crusher (integration of adjustment, cavity clearing, and control, with a high degree of automation)

Material characteristics: Before selecting a hydraulic cone crusher, the characteristics of the material to be processed must be considered. Such as hardness, humidity, abrasiveness and so on;

Capacity requirements: Select the right model according to the actual processing capacity, including the required output size, capacity and production;

Finished product size: select the cavity type according to the particle size control needs, medium crushing (M medium cavity type), fine crushing (F fine cavity type), ultra-fine crushing (EF ultra-fine cavity type);

Cost and budget considerations: Operators should evaluate their budget and consider the total cost of ownership, including purchase price, operating costs and maintenance. This analysis will help ensure that the investment is cost-effective;

Service and support: Choosing a manufacturer that offers comprehensive maintenance and support services is critical to ensuring the long-term reliability of the cone crusher.

Regularly check the hydraulic oil level to ensure that the oil is clean and the oil level is appropriate, and check the oil pump and pneumatic hydraulic cylinder for leakage;

Do a good job of lubrication and maintenance, refuel on time, check the bearing lubrication to avoid overheating and wear;

Pay attention to the condition of wearing parts, often check the wear of crushing cone and liner plate, and replace them in time when they are found to be seriously worn;

Adjust the discharge opening, according to the production needs of regular adjustment, to ensure the stability of the finished product particle size;

Test the cavity clearing function to ensure that the hydraulic cavity clearing system can smoothly remove the blockage;

Check the equipment as a whole, check whether the fasteners and transmission devices are firm to prevent loosening and abnormalities;

Doing regular maintenance work will help to extend the life of the equipment and improve production efficiency.

Taken together, hydraulic cone crushers excel in performance, ease of operation and maintenance. If you are looking for a medium and fine crushing equipment with high efficiency, stable operation and controllable maintenance cost, you may want to consider XinHai Mineral Processing EPC, a manufacturer with mature technology and perfect support services. Its hydraulic cone crusher has passed ISO9001:2000 international quality management system certification and CNAS international certification, equipped with intelligent Internet of Things system to monitor the health status of the equipment in real time, to provide a global joint warranty service network and 48-hour rapid response mechanism. It can help to reduce the overall operating costs and enhance the long-term benefits of the equipment while meeting the production demands.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.