products

[Introduction]: Hydraulic cone crusher is a kind of crushing equipment with a hydraulic system to adjust the mine outlet, and used for overload protection.

[Capacity]: 5~750t/h

[Improvement]: The supports at both ends of the cone crusher main shaft, scientific design of crushing chamber, double insurance control of hydraulic and lubricating system.

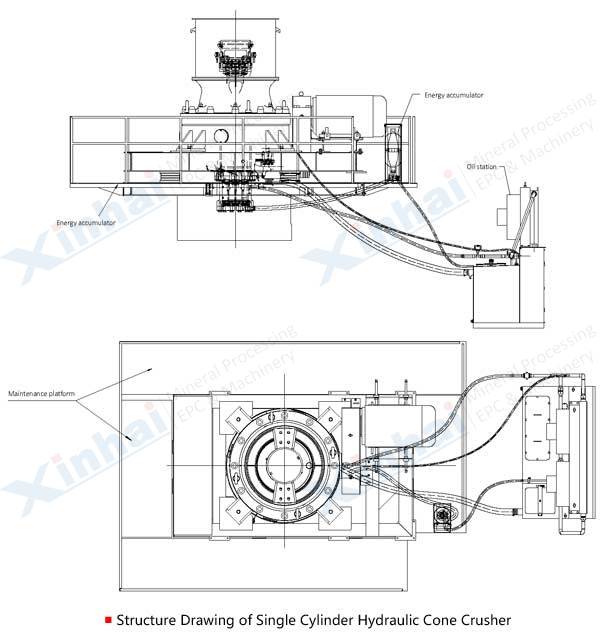

Hydraulic cone crusher consists of the frame, transmission, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs and hydraulic pressure station for adjusting discharge opening. During operation, the motor drives eccentric shaft shell to rotate through a horizontal axle and a pair of bevel gear. The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crushing wall is close to the roll mortar wall from time to time. In this way, the ores and rocks will be pressed and crooked and crushed.

| Model | Cavity | Inlet Dimension (mm) | Max. Feed Size (mm) | Min. Outlet Dimension (mm) | Max. Feed Dimension (mm) | Power (kW) | Weight (t) | ||||

| Stroke | Stroke | Stroke | Stroke | Stroke | Stroke | ||||||

| PYY100 | 16 | 22 | 16 | 22 | 90 | 6 | |||||

| A | 150 | 120 | 12 | 15 | 39 | 37 | |||||

| B | 130 | 105 | 10 | 11 | 33 | 31 | |||||

| C | 100 | 85 | 7 | 9 | 33 | 30 | |||||

| D | 40 | 32 | 5 | 6 | 31 | 29 | |||||

| PYY200 | 18 | 25 | 18 | 25 | 160 | 10.6 | |||||

| A | 220 | 180 | 18 | 22 | 35 | 30 | |||||

| B | 150 | 120 | 15 | 19 | 35 | 30 | |||||

| C | 80 | 60 | 9 | 12 | 35 | 30 | |||||

| D | 40 | 32 | 6 | 8 | 35 | 30 | |||||

| PYY300 | 25 | 32 | 25 | 32 | 250 | 18.5 | |||||

| A | 230 | 190 | 20 | 25 | 45 | 40 | |||||

| B | 150 | 125 | 17 | 20 | 45 | 40 | |||||

| C | 80 | 60 | 10 | 13 | 40 | 35 | |||||

| D | 40 | 32 | 6 | 8 | 40 | 35 | |||||

| PYY500 | 25 | 32 | 40 | 25 | 32 | 40 | 315 | 22.5 | |||

| A | 230 | 180 | 22 | 26 | 30 | 50 | 45 | 40 | |||

| B | 150 | 125 | 19 | 22 | 26 | 48 | 43 | 38 | |||

| C | 100 | 80 | 12 | 14 | 16 | 40 | 35 | 30 | |||

| D | 50 | 40 | 8 | 10 | 12 | 30 | 25 | 20 | |||

| Model | Stroke | Tight Selvedge Outlet (mm) and Corresponding Production Capacity (t/h) | ||||||||

| 8 | 12 | 16 | 20 | 25 | 30 | 35 | 40 | 45 | ||

| PYY100 | 16 | 35~40 | 45~55 | 55~65 | 65~75 | 75~85 | 90~100 | 105~115 | ||

| 22 | 45~50 | 55~65 | 65~75 | 75~90 | 85~105 | 100~125 | 115~135 | |||

| PYY200 | 18 | 65~75 | 75~90 | 85~105 | 100~125 | 135~150 | 160~175 | 170~190 | ||

| 25 | 90~110 | 110~130 | 125~155 | 160~180 | 185~210 | |||||

| PYY300 | 25 | 100~120 | 110~135 | 130~160 | 150~180 | 170~200 | 200~230 | 230~260 | 250~290 | 270~310 |

| 32 | 110~135 | 130~150 | 160~200 | 180~220 | 200~250 | 230~280 | 260~310 | 280~320 | 300~340 | |

| PYY500 | 25 | 100~120 | 120~150 | 140~170 | 160~190 | 190~220 | 220~250 | 250~280 | 280~310 | 330~370 |

| 32 | 150~170 | 170~200 | 200~230 | 250~270 | 280~300 | 310~340 | 370~420 | 430~500 | ||

| 40 | 180~200 | 210~240 | 250~280 | 300~330 | 330~380 | 370~420 | 430~500 | |||

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.