Manganese ore beneficiation equipment is mainly determined according to the properties of manganese ore and manganese ore beneficiation process. There are flotation cell, gravity separator and magnetic separator. In addition, there are pre-selection equipment, post-selection dehydration equipment, etc. The specific equipment types are as follows:

Manganese ore flotation equipment is mainly suitable for processing fine-grained or fine-grained manganese ore. It is mainly to use the floatable properties of pharmaceuticals and minerals to separate them from gangue minerals. The main application of flotation cells are: SF, JJF, XCF, KYF and BF.

KYF: This type of flotation cell is suitable for roughing and selection in medium and large manganese ore dressing plants.

JJF /XCF : They are suitable for roughing and sweeping in medium and large manganese ore dressing plants.

BF: This flotation cell machine is suitable for roughing or selecting operations in medium and small concentrators.

Gravity separation equipment is mainly suitable for processing minerals containing silicon (such as SiO2) and coarse-grained manganese minerals in manganese ore (but most of them are combined with other industries. Such as: gravity-magnetic or gravity-flotation, etc.). The main application of gravity separation equipment are: jig, shaking table, cyclone and so on.

Jig machine: The jig machine is suitable for processing coarse-grained manganese minerals and has a better effect on desilication. At the same time can also remove part of the iron.

Shakers/Cyclones: This type of equipment is widely used to process fine-grained manganese minerals.

If manganese ore often contains iron (iron oxide) impurities, strong magnetic separation is often used to remove iron during beneficiation. The main application equipments are: wet high-grade magnetic separator, high-gradient magnetic separator and dry high-speed magnetic separator, etc.

Wet magnetic separator/high gradient magnetic separator: it is mostly used for iron removal of fine-grained ferromanganese minerals.

Dry magnetic separator: Dry magnetic separator is suitable for removing iron from coarse-grained manganese iron ore.

The main purpose of the manganese ore pre-separation equipment is to crush the manganese ore to a certain particle size, which is convenient for the later selection. Its equipment is mainly crushing equipment, screening equipment, grinding equipment and grading equipment.

Crushing equipment: jaw crusher is mainly used for coarse crushing, and cone crusher is mainly used for fine crushing.

Screening equipment: self-determined center vibrating screen can be used for fine particle screening, and circular vibrating screen can be used for coarse particle screening.

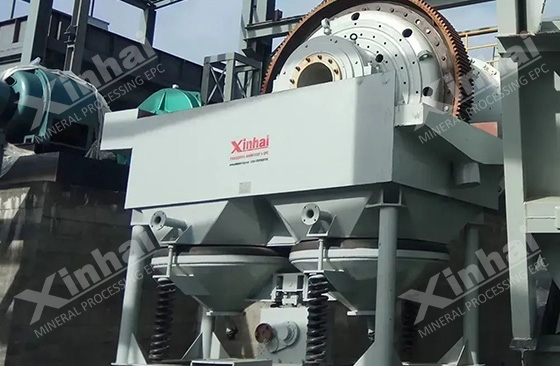

Grinding equipment: grid type ball mill is used for rough grinding operation, and overflow type ball mill is used for fine grinding operation.

Classification equipment: Spiral classifier and grid ball mill can be used for coarse particle classification. Hydrocyclone (group) with overflow type can be used for fine grinding and classification.

Manganese ore dehydration equipment can be divided into two categories, one is manganese concentrate dehydration, and the other is manganese tailings dehydration. According to its dehydration requirements, there are several commonly used concentrators, dehydration screens, cyclones, filter presses and filters.

Thickener: It is mainly suitable for concentrate/tailings dewatering. One more stage of dehydration is performed in the concentrate, and the second stage of dehydration is performed in the tailings, and the underflow concentration is 60~70%.

Dewatering screen: Dewatering screen is mostly used for tailings dewatering. It is used for three-stage dewatering operation, so that the final moisture content of tailings is 12~15%.

Cyclone: The hydrocyclone is used for the first stage of dehydration in tailings dewatering, and the water content of the underflow is 40-30%.

Filter presses/filters: They can be used for dewatering of fines/tailings, mostly in the final stage. The moisture content of the pulp is lower than 9~12%.

The above are common manganese ore beneficiation equipment. The specific equipment model should be determined according to its processing capacity and demand. Xinhai can provide users with manganese ore beneficiation solutions and complete sets of manganese ore beneficiation equipment. Welcome to consult.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.