Gold ore beneficiation is a complex process involving a variety of physical and chemical methods, through which the valuable gold components present in the ore are extracted. Due to the variety of gold ore types (such as quartz vein type, sulfide ore type, oxide ore type, etc.), the gold ore beneficiation methods and dressing equipment required are also different. Therefore, the correct selection of suitable ore dressing equipment is crucial to improve the recovery rate and grade of gold ore. Let's take a look at what equipment is required for gold ore beneficiation plants!

Gravity separation technology is mostly suitable for processing ore containing coarse gold, such as alluvial gold, which often exists in the form of natural gold, with relatively large particle size and obvious density difference with sand and gravel. Ideal gold concentrate can be directly obtained by gravity separation. The gold ore beneficiation equipment required for this method mainly includes spiral chute, jig and shaking table.

Spiral chute: suitable for processing coarse gold ore, with high requirements for the particle size and density difference of the ore, and is often used in the primary separation of alluvial gold ore. The gold separation equipment has a simple structure, large processing capacity and low cost.

Jig: mainly suitable for processing medium and coarse gold ore, with strong adaptability to the particle size range of the feed, and is frequently used in the gravity separation of alluvial gold and vein gold mines. The equipment has good stratification effect, large processing capacity and high recovery rate.

Shaking table: mainly suitable for processing fine gold ore, requiring a stable working environment, and strict requirements for feed concentration and particle size. The equipment has high sorting accuracy and can obtain high-grade concentrate.

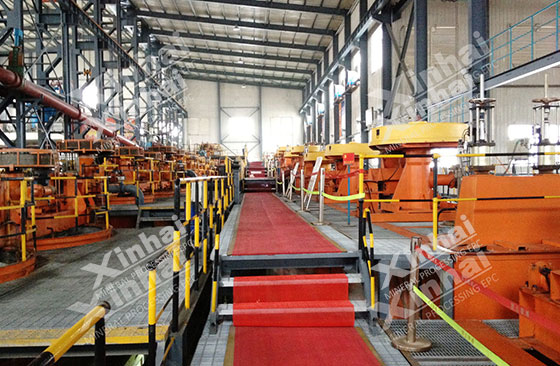

The process of gold flotation is based on the difference in the surface properties of minerals. By adding flotation agents (such as collectors, frothers, regulators, etc.), the affinity of gold minerals and bubbles is enhanced, so that they adhere to bubbles in the pulp and rise to the surface of the pulp to form a foam layer, thereby separating gold minerals from waste rocks. It is mostly suitable for processing gold ores containing sulfide minerals and natural gold particles. The gold ore beneficiation equipment required for this method is mainly flotation machines, and reagent stirring requires a reagent stirring tank or an ordinary stirring tank.

Floatation machine: The flotation machine equipment commonly used for gold beneficaiton is a mechanical stirring flotation machine, an aerated stirring flotation machine, and a flotation house (less used). Among them, the mechanical stirring flotation machine has a large stirring intensity and a large amount of aeration, which can make the pulp fully suspended and the bubbles dispersed evenly. It is suitable for gold ores of various particle sizes and floatability, and has a strong processing capacity for large-scale beneficiation plants; the aerated stirring flotation machine has a large aeration volume, low energy consumption, and relatively weak slurry stirring. It is more suitable for flotation operations that are easily oxidized gold ores and require a high amount of aeration; the flotation column has a small footprint and high flotation efficiency, especially for fine-grained gold ores. It is more suitable for processing fine-grained gold ores and is more sensitive to changes in pulp concentration and flow rate.

Agitation tank: It provides auxiliary operations for the flotation machine, used to dissolve and mix various reagents required for flotation to ensure uniform contact between the reagents and the pulp. Xinhai commonly uses three types of reagent agitating tanks, high-efficiency agitating tanks and ordinary agitating tanks.

Cyanide gold extraction is a method of dissolving gold from ore by utilizing the characteristics of gold that can react chemically with cyanide (such as sodium cyanide or potassium cyanide) solution to generate stable gold-cyanide complexes, and then recovering gold from the solution through further treatment. The gold ore beneficiation equipment required for this method mainly includes leaching tank, adsorption tower, activated carbon adsorption device, analytical electrolysis equipment, air lift, thickener, etc.

Leaching tank: mainly used for the cyanide leaching process of gold mines, which can ensure that gold and cyanide react fully. The equipment has strong adaptability to the concentration and particle size of the ore pulp, and the equipment has a large volume and uniform stirring.

Adsorption tower: used to treat low-concentration gold-containing solutions, it can effectively adsorb gold-cyanide complexes to achieve gold enrichment, but it has certain requirements for the flow rate and temperature of the solution.

Activated carbon adsorption device: activated carbon can adsorb gold ions in the cyanide solution of gold mines. The device has high adsorption efficiency and strong capacity; the equipment is compact, occupies a small area, is easy to maintain and manage, and has low operating costs; it can treat a variety of organic waste gases; it adopts an automated control operation design, which is easy and safe to operate; it is fully enclosed and can be used indoors and outdoors.

Analysis electrolysis equipment: It is used to parse out the gold in the gold-loaded carbon, usually by electrolysis. The characteristics of this equipment are high degree of automation, simple operation, and high analysis efficiency.

Air lift: It is a gold ore dressing equipment that uses compressed air as a transmission medium to transport slurry. The air lift has high efficiency and the carbon stringing time is about 0.5-1 hour each time; it is small in size and easy to install on the leaching stirring tank or adsorption tank, and it is easy to operate and maintain.

Thickener: In the cyanide beneficiation process, the thickener is used to concentrate the slurry and increase the concentration of gold ore. It can increase the content of solid particles in the slurry and reduce moisture, thereby improving the efficiency of subsequent treatment.

The above are the gold ore beneficiation equipment required by the gold ore beneficiation plant. In addition, there are some auxiliary equipment and pre-selection equipment, such as crushers, ball mills, classifiers, filter presses, slurry pumps, etc. When selecting equipment, multiple factors need to be considered comprehensively, including the nature of the gold ore, the scale of beneficiation, process requirements, equipment performance, operating costs, maintenance management, etc.

Xinhai Mining has very rich experience in gold ore beneficiation. It can not only provide beneficiation tests, but also carry out gold ore process design. Moreover, there are 29 innovative process technology solutions in gold ore beneficiation alone, such as granular gold or heavy mineral-rich, rich ore-containing gold beneficiation technology, gold oxide primary mixed ore gravity selection + flash flotation technology, easy-to-select gold ore flash flotation technology, easy-to-grind and difficult-to-grind mixed gold ore innovative beneficiation technology, etc.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.