The customer of the Laos 2000TPD gold ore dressing plant project selected Xinhai Mining after multiple inspections and comparisons. During the design process of the dressing plant, Xinhai Mining appropriately added new equipment and processes based on the original flotation dressing plant to make full use of the existing factory buildings, equipment and foundation, as well as the scientific and reasonable design of the dressing plant, ensured the smooth flow of the entire dressing plant, and the normal operation of new and old equipment. It not only achieved the expected recovery rate, but also saved investment costs. The final gold mine recovery rate was 87 %-95%, customers are very satisfied with the results of the dressing plant transformation.

The Henan 3000TPD gold ore dressing plant project is a transformation project undertaken by Xinhai Mining. Xinhai Mining customized a complete set of equipment in the gold mine flotation production line for the project, mainly including ball mill, flotation machine, thickener, agitation tank and other equipment and accessories. Technical personnel improved the mineral processing equipment based on the original dressing plant conditions to make it consistent with the process flow and dressing plant foundation to ensure smooth operation of the project site.

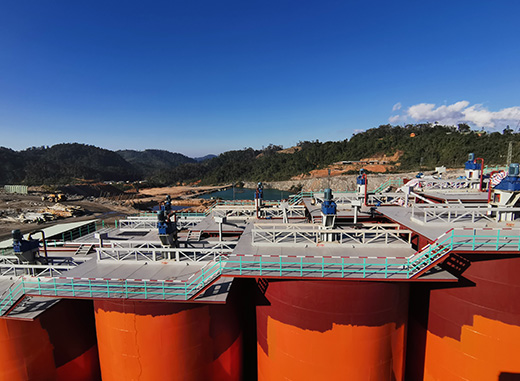

In 2018, the customer initially entrusted Xinhai Mining to provide full industry chain services for its 4000tpd gold ore dressing plant. The comprehensive gold recovery rate of the plant was about 90%. Later, it expanded to 6000tpd on the original basis and entrusted Xinhai again. Mining Equipment provides one-stop, customized mining industry chain services (EPCM+O) for its 6,000tpd gold ore dressing plant project. It was officially put into production in just 8 months, achieving considerable economic benefits.

More details >>

Xinhai Mining provides customized EPCM+O Service for the Mongolian 2 million TPA gold concentrator project, and provides gold smelting construction engineering design according to customer needs, including process expertise, civil engineering Professional design in all aspects including electricity, water supply and drainage, and heating. Under the influence of the epidemic environment, the Xinhai Mining Installation and Debugging Team overcame difficulties and arrived at the gold mine project site as soon as possible to participate in and manage the equipment installation and commissioning of the project and provided professional maintenance and training services.

More details >>Gold mine heap leaching-adsorption-desorption electrolysis-activated carbon pickling and regeneration-smelting process plan.

This project is another cooperation between Xinhai Mining and the project customer. According to the needs of customers, Xinhai Mining designs and layouts the cyanide leaching system, pharmaceutical preparation system, desorption electrolysis system, smelting system, etc. In order to complete the project and put it into production as soon as possible, Xinhai Mining worked overtime to produce and ship equipment within the limited construction period, overcoming numerous difficulties, completing the project production tasks ahead of schedule, and effectively advancing the project progress.

Gold all-sliming cyanidation process.

Entrusted by the project company, Xinhai Mining provided EPCM+O Service, including engineering, procurement, construction,management and operation for the Iranian 500TPD gold ore dressing plant project. After the project was put into operation, it achieved good recycling benefits and the customer was very satisfied with it.

According to the commissioning requirements of the Guinea 3000TPD gold mine project, Xinhai Mining has built a new 3000t/d gold mine carbon slurry plant for the project. It uses advanced and reliable process technology and large-scale and efficient mineral processing equipment to save investment as much as possible. After debugging, it has been Achieve standards and production and meet customer expectations.

Local gold deposits are divided into two industrial types, one is surface laterite type ore, and the other is quartz vein type ore in weathered rock and semi-weathered original rock below the laterite layer. Laterite type ore body is an unconsolidated gold-bearing ore body. Laterite, consolidated calcareous rock, calcareous conglomerate, 80% of the ore is powdery clay ore, containing granular gold, gold is the only recoverable element.

More details >>one stage of open circuit crushing - one section of closed circuit grinding and classification - leaching and adsorption - desorption and electrolysis

Xinhai Mining provides services including mine design and equipment customization for the Myanmar 500TPD gold mine project. According to the project characteristics and actual conditions, Xinhai Mining designs and customizes gold concentrator equipment. The metal minerals in the ore mainly include pyrite, sphalerite, pyrrhotite, ilmenite, chalcopyrite, with a small amount of natural gold, trace tellurite, etc. Non-metallic minerals mainly include quartz, plagioclase, chlorite, mica, dolomite, calcite, and a small amount of amphibole. Among the useful minerals, the main one is natural gold. The gold mine project was successfully put into production after commissioning and commissioning, and achieved good mineral processing indicators.

Two-stage and one-half closed-circuit crushing and screening-two-stage grinding and classification-leaching adsorption-desorption electrolysis

According to customer needs, Xinhai Mining has technical communication with customers and provides a complete gravity separation process design. The processing capacity can reach 600-800t/d, meeting customer expected needs. After the equipment arrives locally, Xinhai Installation Team arrived at the project site to provide installation guidance, and the recovery rate met expectations.

The 3 million TPA gold heap leaching project undertaken by Xinhai Mining was successfully put into operation. The project adopted Xinhai Mining EPCM+O service. After the complete set of equipment for the gold mine project was manufactured, Xinhai Mining used a complete packaging and shipping management system to safely deliver all equipment to the project site. Due to the harsh climate of the Mongolian Plateau and the severe cold and long winters, the complete set of gold mining equipment manufactured by Xinhai Mining Equipment can work all day long at a temperature of minus 35°C, providing a strong guarantee for improving the quality and efficiency of the gold mining project!

More details >>Crushing-heap leaching-desorption electrolysis-smelting

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.