Since its establishment 20 years, Xinhai has been committed to the Research and development of extraction of gold, including gold extraction technology and equipment, after the constant study of Xinhai research technicians, Xinhai has formed a set of efficient, environmental, energy-saving and economic Xinhai CIL gold processing.

Recommend Xinhai gold flotation process for small gold plant.

Leaching Pulp Preparation

Leaching Pulp Preparation

Cyaniding Leaching and Carbon Adsorption

Cyaniding Leaching and Carbon Adsorption

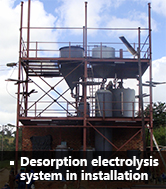

Gold Loaded Carbon Desorption

Gold Loaded Carbon Desorption

Pregnant Solution Electrodeposit

Pregnant Solution Electrodeposit

Carbon Acid Regeneration

Carbon Acid Regeneration

Leaching Pulp

Leaching Pulp

If you have any questions, please contact us by the following ways, and we will provide you with better help!

Add the gold ore slurry into 9 leaching agitation tanks, pour in cyanide solution in first 2 tanks, activate carbon in the following 7 tanks for the reverse-absorption process (the number of tanks depend on the capacity size).

Xinhai special coconut shell activated carbon

Xinhai special coconut shell activated carbon is featured with small hole, high reaction activity, wear-resistance and renewability, the adsorption speed increases 30%.

Xinhia Global CIL Gold Processing Plants Collection

Xinhia Global CIL Gold Processing Plants Collection

If you have any questions, please contact us by the following ways, and we will provide you with better help!

In January 2015, Xinhai undertook Tanzania 1200tpd CIL gold processing plant of a mining company, the project adopted Xinhai gold CIL process, after construction design and installation, it has been put into production now, the recovery rate of gold production line reached expected goal, the final gold leaching rate was 91.5%, which brought large amount of economic benefits for clients and obtained high praise from clients.

In March 2015, Xinhai took charge of African Zimbabwe Huangzhi 700tpd CIL gold processing plant, the plant is mainly quartzite gold mine, most is oxidized ore or primary ore with low sulfur ore, so Xinhai chose gravity separation + all-sliming CIL process, which achieved efficient extraction of gold, save 15% cost. Equipment still operate smoothly after put into production one year, customer are very satisfied with this result.

Xinhai has make Class B design Qualification, set up mine design institute and mineral processing research institute, more than 200 professionals provide the technical support service for the extraction of gold, Since its establishment 20 years, Xinhai has been committed to the development and innovation of process and equipment used in the extraction of gold, and has formed the complete extraction of gold system. Xinhai concentrates on providing the Turnkey Solution for Mineral Processing Plant that is research and design- complete equipment manufacturing and procurement- commissioning and delivery”, striving for building the international leading enterprise in the extraction of gold.

"Create a global brand, based on global gold markets " has been one of the strategic thought of Xinhai, depending on its professional gold processing service, Xinhai has got the EU certification, and ISO9001:2015quality management system certification, Xinhai is classified as the assured brand with advanced products and standard quality!

Xinhai currently has many patents technologies, the extraction of gold plants spread among China, Southeast Asia, South America, Africa, Russia, Mongolia, North Korea and other places, and Xinhai has established offices around the world.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.