Various types of crushers are widely used in the sand and gravel aggregate production industry, typically following the blasting and mining process. While their core function is to break large rocks into smaller particles, they are used in different stages of crushing—primary, secondary, tertiary, and even quaternary—depending on the material and end-product requirements.

This article explains how crushers work and the six common types of crushers, along with their respective crushing stages, to help you select the right equipment and save time and money.

A crusher is a mechanical device designed to break large rocks, ores, or other solid materials into smaller, more manageable pieces. It is widely used in various industries, including mining, construction, aggregate production, recycling, and mineral processing.

Crusher breaks materials by applying mechanical forces such as compression, impact, or abrasion. The specific method depends on the type of crusher and the nature of the material being processed.

Based on their operating principles, crushers can be divided into two main categories:

Compression crushing: Material is crushed by continuous pressure between two crushing surfaces. This principle is widely used in jaw crushers, cone crushers, gyratory crushers, and roller crushers. Characterized by a high crushing ratio and angular, well-defined finished particles, it is suitable for coarse and medium crushing of medium- to high-hardness materials.

Impact crushing: In this method, high-speed moving parts strike the material, breaking it using kinetic energy. Typical equipment includes impact crushers, hammer crushers, sand-making machines, and vertical compound crushers. This crushing method is particularly suitable for processing brittle materials, resulting in rounded finished particles. It is often used in aggregate shaping and sand production.

The following introduces six common types of crushers and their key advantages:

1. Jaw Crusher

A jaw crusher crushes materials through periodic compression between fixed and movable jaw plates. It boasts a simple structure, high crushing ratio, strong adaptability, and easy maintenance. It is typically used in the initial stage of the crushing process—the coarse crushing stage—and is suitable for processing large, hard ores.

2. Cone Crusher

A cone crusher utilizes a rotating cone, driven by an eccentric sleeve, to oscillate, crushing the material through interparticle compression. It offers advantages such as high crushing efficiency, high output, uniform product size, and strong wear resistance. It is typically used in the secondary and tertiary stages of the crushing process and is suitable for processing ores and stones with medium to high hardness, such as iron ore, copper ore, and quartz stone.

3. Hammer Crusher

A hammer crusher uses high-speed rotating hammers to strike the material, crushing it under the impact force. It combines impact, shearing, and grinding actions. It has several advantages, including a simple structure, one-step crushing, adjustable output particle size, and suitability for materials with high moisture content. It is typically used in the primary or secondary crushing stages of the process and is suitable for processing medium- to low-hardness, brittle materials, such as limestone and shale.

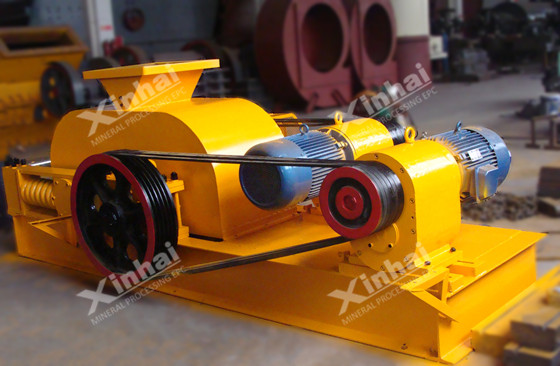

4. Roller Crusher

A roller crusher uses a pair of rotating rollers to crush the material. Material is fed into the gap between the rollers, where it is compressed and crushed as the rollers rotate. It is commonly used as a tertiary crushing device for medium- to low-hardness and brittle materials. It is particularly well-suited for materials with a certain degree of stickiness or a high moisture content (up to 30%), such as coal, limestone, and clay.

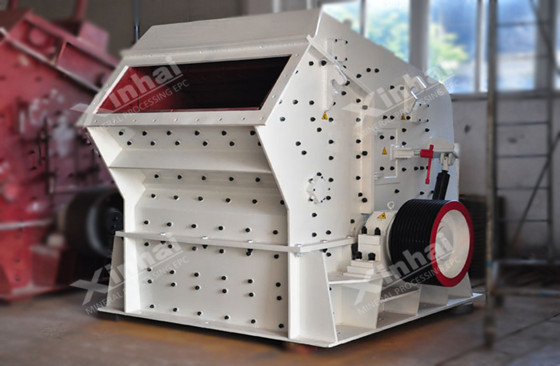

5. Impact Crusher

Impact crushers include vertical shaft impact crushers (VSI) and horizontal shaft impact crushers (HSI). They are best suited for less abrasive rock types, such as limestone. These crushers use the impact force of high-speed rotating components (such as the impact plate and blow bars) to break the material.

6. Mobile Crusher

Mobile crushers, often referred to as "mobile crushing plants," are track-mounted crushing equipment. Their mobility maximizes productivity and reduces operating costs, while also improving safety and minimizing environmental impact.

Choosing the right crusher is crucial to ensuring smooth project execution and achieving the desired production efficiency and product quality. The following are 5 key factors to help you make the best choice:

1. Identify the Ore Properties

Hardness: For high-hardness ores like quartzite and iron ore, a jaw crusher + cone crusher combination is generally used; for soft or brittle materials, a hammer crusher or impact crusher can be considered.

Moisture Content: For materials with high moisture content, choose equipment with high moisture tolerance, such as a roller crusher or hammer crusher.

Abrasiveness: For highly abrasive ores (such as silicate ores), equipment with long-life wear parts, such as a hydraulic cone crusher, is recommended.

2. Processing Capacity

Determine the required hourly production capacity. For large production lines, choose a gyratory or cone crusher; for small and medium-sized production lines, choose a jaw or impact crusher.

3. Target Product Particle Size

Primary Crushing: Jaw crushers, gyratory crushers, and hammer crushers are used to reduce large lumps to medium sizes.

Secondary Crushing: Cone crushers or impact crushers are used to reduce the material to smaller particles further.

Fine Crushing: Tertiary crushing is performed using a sand maker, roller crusher, fine crusher, or compound crusher to produce fine sand or powder.

4. Application

Stationary crushers are not suitable for projects requiring frequent site changes. However, due to their robust structure, high processing capacity, and low maintenance costs, they are well-suited for mining and large-scale construction projects.

Mobile crushers and wheeled crushers are ideal for projects that require site flexibility and mobility. They are easy to install, highly maneuverable, versatile, and can be quickly deployed.

5. Operation and Maintenance Costs

Hammer crushers and impact crushers are suitable for low-abrasive materials and have low operating costs, but they require frequent replacement of wear parts.

Cone crushers have a higher initial investment, but they offer high wear resistance and long maintenance intervals, making them suitable for long-term operation.

Conclusion

Finally, selecting the optimal equipment requires a comprehensive analysis of your project, including material properties (such as hardness, strength, and moisture content), site location, and a thorough cost analysis. Different operating conditions require different solutions.

If you require a more detailed analysis and customization tailored to your specific crushing needs, or a comprehensive mining, beneficiation, and processing solution for a particular mineral type, please contact us. Xinhai Mining, with over 30 years of design and practical experience, can help you make the best choice.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.