The main component of quartz sand is silica, and the quartz sand is often accompanied by small or trace impurities. With the exhaustion of natural crystals, it has become an inevitable trend to extract high-purity quartz from ordinary quartz sand, so it is necessary to purify quartz sand, obtaining the refined quartz sand or high-purity quartz sand.

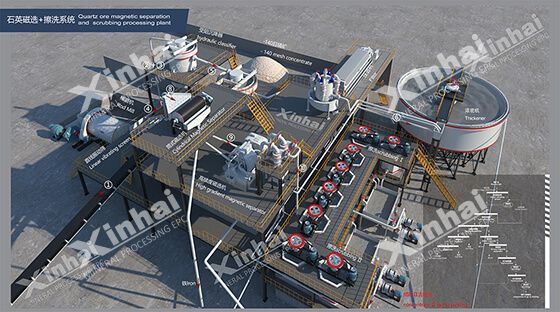

The quartz sand beneficiation processing is to remove the impurity minerals contained in the raw ore. In the production, the common quartz sand beneficiation processing mainly includes the washing desliming method, magnetic separation method, flotation method, and acid pickling method.

There are a variety of mineral impurities in quartz sand, and the grades of different impurities have a close relationship with the particle size of quartz sand. For example, the grade of SiO2 decreases with the decrescence of quartz sand particle size, and the impurities such as Fe, Al grade will rise with the decrescence of quartz sand particle size, this kind of phenomenon in clay minerals quartz sand is particularly significant. Therefore, it is necessary to carry out ore washing and desliming treatment.

The commonly used quartz sand processing washing method is mainly the scrub method (rod mill scrubbing and mechanical scrubbing). In production, the rod mill scrubbing effect is more ideal than mechanical cleaning. The scrubbing concentration is kept at 50% ~ 60%, and the scrubbing time is determined according to the ore nature, which is based on initially meet the product quality requirements. And the time should not be too long to avoid too much energy consumption and equipment wear.

In addition, in the quartz sand scrubbing processing, the scouring reagent can be added to change the composition of mineral particles, enhance the scrubbing effect and improve the efficiency of impurity removal.

Used to treat the quartz sand containing a large number of clay and mud, or used to remove the film iron and adhesive impurities on surface of the quartz sand.

High-efficiency agitator washer, hydrocyclone, rod mill, hydraulic classifier, desliming bucket

The magnetic separation method is based on the magnetic difference between quartz sand and associated impurities minerals. Low-intensity magnetic separation is often used for the strong magnetic minerals, while high-intensity magnetic separation is mainly used for the weak magnetic minerals, and the magnetic field intensity should be more than 10000Oe.

It should be noted that the number of magnetic separations and magnetic field intensities should be effectively controlled when using the magnetic separation method. In general, with the increase of magnetic separation times, the iron content in the ore will decrease, but most of the iron can be removed only under a certain magnetic field intensity. In addition, the effect of iron removal is also related to the size of quartz sand. Usually, the smaller the size of quartz sand, the better the effect of iron removal.

Often used to remove the weak magnetic impurities (eg. hematite, limonite, biotite) and strong magnetic minerals (eg. magnetite) contained in the quartz sand.

Magnetic separator, High-intensity magnetic separator (eg. high gradient magnetic separator)

If the scrubbing, washing and desilming, magnetic separation methods cannot achieve the ideal beneficiation effect, the flotation method can be considered to remove the mica and feldspar from quartz ore.

■ Mica removal: the cationic collector is used under the condition of pH value 3-4.

■ Feldspar removal: In acidic conditions, fluorine flotation and fluorine-free flotation are used according to the different flotation reagents. The fluorine flotation means using the cationic collector to preferentially float feldspar under the activation of strong acid and fluorine ions. The fluorine-free flotation means to adopt the anionic collector dodecyl sulfonate and diamine cationic collector together, then the anionic collector complexes with the diamine collector adsorbed on the feldspar surface to form co-adsorption and improve the hydrophobicity of feldspar surface.

Mainly used to remove feldspar, mica, and various non-magnetic associated impurities in the quartz sand.

Suction mechanical agitation flotation machine (SF flotation machine, BF flotation machine, JJF flotation machine), inflation mechanical agitation flotation machine (KYF flotation machine, XCF flotation machine)

The quartz isn’t insoluble in acid (except HF), while the acid solution can dissolve other impurities. Therefore, the acid pickling method can be used in quartz beneficiation.

The commonly used acids in quartz sand pickling include sulfuric acid, hydrochloric acid, nitric acid, hydrofluoric acid, etc. Dilute acid has a good effect on removing iron, aluminum, and magnesium, while the concentrated sulfuric acid and hydrofluoric acid have a good effect on removing titanium and chromium. According to the production practice, the mixed acid has a better effect on quartz sand beneficiation and purification.

Quartz sand contains iron, aluminum, magnesium, titanium, chromium, and other impurities, and the requirements on the purity of quartz sand are high.

In the actual beneficiation process, the quartz sand beneficiation processing often needs to be determined comprehensively according to the ore properties, concentrator conditions, investment budget, and other factors. It is suggested to carry out the mineral processing test, then select the single or combined process through the beneficiation test report, striving for the ideal technical and economic benefits.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.