Quartz sand, also known as silica sand (quartz sand with SiO2 content above 98.5%, silica sand with SiO2 content below 98.5%), can be made into high-purity quartz sand after the mineral processing and purification. It is widely used in glass, ceramics, metallurgy, casting and refractory industries.

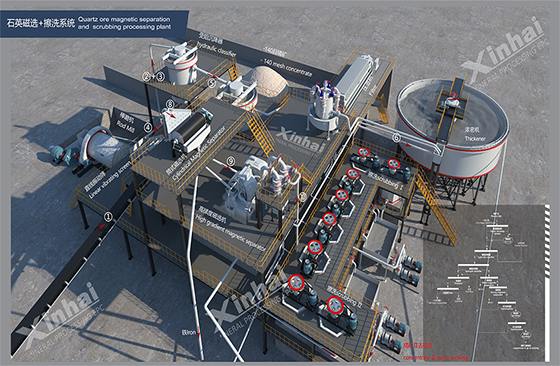

At present, the common quartz sand processing process is to remove the mineral impurities from the quartz sand by scrubbing and desliming, magnetic separation, gravity separation with the chute, flotation, acid washing or combined operation of several methods to obtain high purity quartz sand with the qualified particle size and impurity content. In this process, the commonly used quartz sand processing equipment mainly includes the rod mill, magnetic separator, flotation machine, hindered settler, XCⅢ hydrocyclone, high-frequency and high-efficiency dewatering screens, tilted thickener, scrubbing machine, desliming hopper, slurry pump, etc. Now, let’s learn more about quartz sand processing equipment.

In the process of quartz sand processing plant, rod mills are often used for grinding equipment, which has a better grinding effect, controllable discharge particle size, and a certain scrubbing function.

1)The particle size of the quartz sand grinding discharge is usually between 40 mesh and 120 mesh. The steel rod of the rod mill is in face-to-face contact with the material, which is not easy to over-grinding. At the same time, it ensures the qualified products of grinding and excludes the unqualified products.

2)The use of a rod mill to process the quartz sand plays a role of scrubbing to a certain extent, which can help remove some impurities.

3)The steel rods of quartz sand rod mill have a certain sieving effect on quartz sand in the process of movement, so that large particles can be lifted to the top position of each layer and concentrated to the place where quartz sand can be crushed more strongly.

Magnetic separation is one of the effective methods to remove iron-containing and weakly magnetic impurities as much as possible such as hematite, limonite and biotite including conjoined particles in quartz sand.

Strong magnetic separation usually uses a wet strong magnetic separator or high gradient magnetic separator. Generally speaking, the quartz with limonite, hematite, biotite, and other weak magnetic impurity minerals can be selected by using the wet strong magnetic machine above 10000 GS; for the strong magnetic minerals containing mainly magnetite as impurities, it is better to use weak magnetic machine or medium magnetic machine for separation. In order to further remove a small amount of other weakly magnetic minerals (such as hornblende, pyroxene and magnetic minerals and quartz congeners), a high gradient magnetic separator with a magnetic field strength greater than 12000 Gauss can be used for secondary magnetic separation.

Flotation separation is also widely used for processing quartz sand, mainly to remove non-magnetic accompanying impurities such as feldspar and mica in quartz sand. The quartz sand processing equipment used in this process is various types of suction mechanical agitation flotation cells (SF flotation cell, BF flotation cell, JJF cell) and inflatable mechanical agitation flotation cells (KYF flotation cell, XCF flotation cell).

Before choosing a flotation cell, the quartz sand processing plant can choose a combined unit consisting of KYF flotation cell and XCF flotation cell according to its situation. Among them, XCF is used as a suction tank and KYF is used as a DC tank to achieve horizontal configuration without the need for a froth pump; the U-shaped tank makes the flotation distance as short as possible, the pulp flows to the bottom of the tank, and the rotor is pumped to the gap between the impeller and the stator, which is conducive to the return of coarse and heavy ore particles to the impeller area for recirculation, avoiding the accumulation of ore and reducing the short circuit of the pulp. This combined unit provides not only a new way to configure the flotation cell in the newly-built quartz sand processing plant but also an economic and easy way for the old quartz sand processing plant flotation process transformation.

The hindered settler is a kind of equipment that interferes with settling, mainly composed of a barrel, bracket, feeding port, overflow tank, retaining ring, support seat, pressure detector, electric valve and an automatic control system, etc. It is special equipment especially effective for sorting quartz sand and other non-metals. The material is affected by the rising water flow in the cylinder to achieve the purpose of particle size classification and specific gravity separation, with high production efficiency and low energy consumption. It can be equipped with an automatic control system, which is simple, convenient and easy to control to adjust the operating parameters. The water tank in the lower part of the cylinder can be equipped with a special rubber nozzle device, so that the rising water hole will be closed automatically when the water stops, and the materials in the cylinder can enter into the tank without any clog.

In the quartz sand processing plant, the hindered settler can strictly classify its coarse and fine particles and completely replace the fine screen for size control.

The XCⅢ hydrocyclone has a specially designed fishtail device at the sand sink nozzle and a specially designed siphon device at the top of the overflow box, so it has excellent characteristics that other hydrocyclones can’t match, and through the adjustment of the siphon device, the high bottom flow concentration and low overflow concentration can be obtained. For the silica sand (quartz sand) industry, the discharge from the overflow can be almost water by adjusting, and the underflow concentration can be as high as 85%. In addition, the specially designed fishtail device can keep the discharge concentration and overflow fineness of the underflow of the cyclone cone constant under the condition of the fluctuation of the feeding capacity, feeding concentration and feed pressure within a certain range.

The structure of the high-frequency and high-efficiency dewatering screen includes a vibration motor, a screen, a dewatering screen frame, support, and rubber spring. A High-frequency high-efficiency dewatering screen is new and high-efficiency dewatering equipment with a simple structure, convenient maintenance and simple operation. Because of its large processing capacity and good dewatering effect, it is widely used in the dewatering of fine-grained minerals. In quartz sand processing plant, the high-frequency high-efficiency dewatering screen adopts unique screen plate structure, coupled with high-frequency vibration of the motor, which not only makes the pulp particles hard to pass through the screen holes, but also has higher dewatering efficiency, and finally can get dry pile tailings with water content less than about 15%.

The tilted thickener is a kind of gravity thickening equipment for slurry with inclined parallel plates designed in the settling area. The whole machine includes the upper box and the lower cone.

For quartz sand processing plant, the concentration process of tilted thickener is completed in each independent tilted plate channel, and the fine-grain overflow or clean water is directly discharged from the overflow surface of each channel laterally, which shortens the overflow discharge path and effectively solves the problem. The short-circuit and circulation problems of fine particles in the overflow discharge process ensure a high classification and concentration efficiency. The efficiency of the classification and concentration backwater can generally reach more than 70%. Compared with other thickeners, the tilted thickener used in the quartz sand processing plant can accelerate the separation of ore particles, shorten the material settlement time, strengthen the separation and settlement process, improve the concentration efficiency, reduce the capital investment, and increase the production capacity by about 3 times.

It uses the mechanical force of the scrubbing machine and the abrasive force between the sand grains to remove the thin film iron, bonding and mud impurity deposits on the surface of quartz sand, and further scrub the mineral aggregates that have not become monolithic, and then further purify the silica sand through classification.

At present, quartz sand scrubbing equipment mainly includes high-efficiency agitating scrubbing machines and spiral groove scrubbing machines.

High efficiency agitating scrubbing machine is mainly composed of a motor, reducer, spindle, upper and lower impeller and trough. The motor drives the three layers of specially designed rubber impellers on the main shaft through the hard gear reducer to scrub the materials strongly. The trough is hexagonal, lined with wear-resistant rubber, easy to resist material impact and abrasion. It has a long service life and low failure rate and is suitable for the mineral particle size of 0-6mm natural or artificial sand and various loose mud particles or materials to scrub and purify particles, disperse the mud materials which can effectively remove the solvent and mud attached to the surface of minerals or materials.

The spiral groove scrubbing machine consists of the trough, left and right spiral blade shaft, transmission device and so on. The motor through the reducer and the size of the gear to promote the two spiral shafts relative rotation, the spiral shaft on the blade staggered installation. With the help of rubbing and scrubbing of the blades and the appropriate of high-pressure water rinsing from the upper end of the trough, the mud and the mineral particles adhering to the surface of the mud are broken up and separated from the mineral particles to achieve the purpose of ore washing. The spiral groove scrubber has a good washing effect for quartz sand with a certain proportion of mud content, especially for high viscosity mud masses with a good breaking effect.

The desliming hopper is simple equipment for classification, desliming and concentration. A feeding cylinder is set in the center of the liquid surface, and the bottom edge of the cylinder is submerged below the liquid surface. The slurry is fed into the central cylinder in the tangential direction and flows out from the bottom edge after being buffered. The outflowing slurry flows out radially to the surrounding overflow dam. During this process, coarse particles that settle faster than the ascending speed of the liquid flow will settle in the tank and be discharged through the bottom sedimentation. Generally, the feeding ore particle size is less than 2mm, and the classified particle size is 75um or smaller.

In quartz sand processing plant, the desliming hopper can be used to deslime the quartz raw ore before the hindered settler, so as to improve the classification efficiency; or used for quartz sand concentration and dewatering before the rod mill, so as to improve the feed concentration of the rod mill; or used to control the feed concentration and feed capacity before various quartz sand processing equipment.

The slurry pump is an important slurry conveying equipment in the quartz sand processing plant. Its function is to transport the slurry to the desliming hopper and chamber filter press or other slurry conveying links. The slurry pump is lined with XH wear-resistant rubber, which not only enhances its wear resistance, but also ensures that the desliming hopper and chamber filter press are in good working condition and prolongs the service life of the slurry pump.

In the actual processing process, quartz sand processing process and equipment selection are often based on the property of quartz sand ore, plant conditions, investment budget and other factors to decide. If you want to separate quartz sand more economically and environmentally, it’s recommended to conduct a processing test first to comprehensively analyze the properties of the ore, and get a scientific processing test report, so as to determine the use of quartz sand processing technology and quartz sand processing equipment after considering the actual situation of the processing plant, investment and other factors, and customize the quartz sand processing equipment to achieve the ideal return on investment.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.