Flotation reagents is the key factor to barite ore flotation separation process. The dosage and sort of reagent can influence the adsorption force and stability between the barite and bubble directly. The more reagents, the higher recovery rate of barite ore obtained, but it will also increase the agent consumption and environmental pollution. The kind of flottaion agent should be selected according to raw ore properties and beneficiation process to idealize the flotation effect. The common used flotation regents are collectors, pH regulator and foaming agent. This article will introduce the kinds and characteristics of barite ore flotation agents.

The type and action mechanism of the barite ore flotation collectors should be determined by charge states of barite ore surface and the pH of slurry. The commonly used collector of barite is mainly fatty acid salts.

Fatty acid salt is a substance that can form a complex with barium ions on the surface of barite. It needs to be used under the condition of high pH value, which can make the surface of barite hydrophobic and easy to attach to the air bubbles. Commonly used fatty acid salts include sodium oleate, sodium stearate, and sodium palmitate.

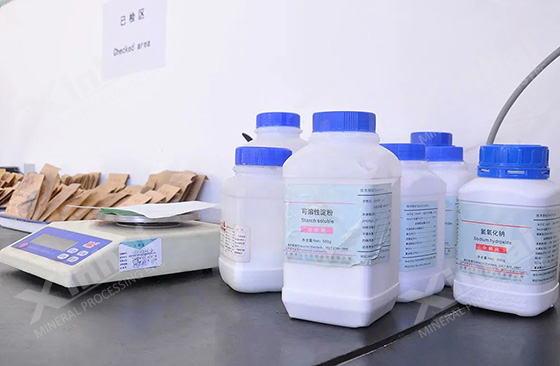

Commonly used pH regulators for barite include alkaline substances, acidic substances and salts. Alkaline substances are substances that can increase the pH value of the pulp, thereby making the surface of the barite negatively charged, increasing the adsorption effect of fatty acid salts, and improving the flotation recovery rate of the barite. Commonly used alkaline substances are sodium hydroxide, sodium carbonate, calcium hydroxide, etc.

Acidic substances are substances that can reduce the pH value of the flotation liquid, thereby making the surface of the barite positively charged, reducing the adsorption effect of fatty acid salts, and reducing the flotation recovery rate of the barite. Commonly used acidic substances are sulfuric acid, hydrochloric acid, oxalic acid and so on.

Salt is a substance that can change the electrolyte concentration of the flotation liquid, thereby affecting the potential difference on the barite surface and the solubility of the collector, and is selected according to different process conditions. Commonly used salts are sodium sulfate, sodium chloride, ammonium sulfate, etc.

Commonly used foaming agents for barite include rosin oil, turpentine oil and alcohols. Retinol is a distilled mixture of pine trees that contains various terpenoids that form emulsions in water and react with oxygen in the air to form stable gas bubbles. Turpentine is a mixture distilled from pine trees that contains various phenolic compounds that form emulsions in water and react with oxygen in the air to form stable bubbles. Alcohols are organic compounds containing hydroxyl groups that form solutions in water and lower the surface tension of water, making it easier for bubbles to form and maintain.

To sum up, the reagents used in barite ore flotation mainly include collectors, slurry regulators and foaming agents. Their dosage and type will directly affect the adsorption force and stability between barite and air bubbles affecting the flotation effect and quality of barite. Therefore, choosing the right agent is one of the key factors in barite flotation. However, the choice of reagents is not static, but needs to be flexibly adjusted and optimized according to the properties of the raw ore and process conditions. In order to achieve the ideal flotation effect, sufficient beneficiation tests are required to determine the appropriate dosage and type of reagents, as well as other operating parameters. The beneficiation test is the basis and guarantee for the design and improvement of barite flotation process, and it is also an effective way to improve the recovery rate and grade of barite.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.