In the gold flotation process, it is necessary to add specific reagents to the slurry to selectively separate and purify gold minerals from gangue minerals and improve the recovery rate of gold concentrate. Due to the different properties of gold ore in different mining areas, the types and doses of agents added are also different. The following will introduce the commonly used flotation agents and their properties during gold flotation to help you better understand gold ore flotation reagents.

Collectors are organic chemicals that selectively attach to the surface of gold concentrate particles to make them more hydrophilic. There are three main collectors commonly used in gold ore flotation: xanthate (xanthate), dithiophosphate and mercaptobenzothiazole.

Xanthate (xanthate salt): Xanthate, as one of the collectors commonly used in gold flotation, can effectively capture gold particles and make the surface hydrophobic, thereby realizing the flotation separation of gold.

Dithiophosphate: it is widely used in the gold flotation process, because they have good adaptability, the flotation of different types of gold ore, the use of dithiophosphate has better collection performance .

Mercaptobenzothiazole: it mainly shows good selectivity in the flotation process of specific types of gold ores.

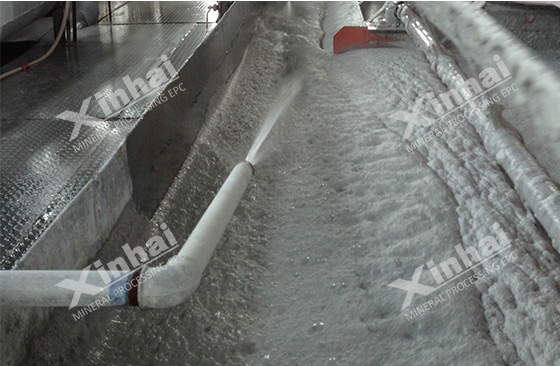

The frother helps the slurry generate stable air bubbles during the flotation process. These bubbles bring the hydrophilic gold particles to the surface so that the foam product can be collected. The frothers commonly used in gold flotation mainly include pine oil and methyl isobutyl carbinol.

Pine oil: Pine oil can effectively generate fine and stable air bubbles, so that the gold particles can be adsorbed on the air bubbles and brought to the liquid surface during the flotation process.

Methyl isobutyl carbinol (MIBC): MIBC has good foaming performance, which can help the pulp to form fine and stable bubbles. It is used together with other flotation reagents, such as collectors and regulators, in the gold ore flotation process to enhance the gold ore separation effect.

These gold flotation foaming agents can be used alone or combined with other flotation agents according to specific flotation conditions and ore properties. Choosing the proper frother can improve the flotation efficiency of gold particles and maximize the recovery of gold.

Modifiers mainly adjust the pH value and other chemical conditions in the flotation process. They enhance the selectivity of collectors and frothers, facilitating the separation of gold from other minerals. Lime and soda ash are commonly used modifiers in gold flotation.

Lime: As an alkaline substance, lime can increase the concentration of OH- in the pulp and increase the pH of the pulp. During flotation of certain gold ores, higher alkaline conditions help to improve the adsorption of collectors and gold ore particles, and increase the recovery rate of concentrates.

Soda ash: Both soda ash and lime are alkaline substances. Adding them to the pulp can increase the pH value and improve the adsorption of gold ore and the recovery efficiency of concentrate.

Gold flotation activators and inhibitors can activate or inhibit the flotation of specific minerals, thus affecting the separation effect of gold and other minerals.

Gold flotation activators refer to chemical substances that can enhance the flotation of gold particles. By chemically reacting with the surface of gold minerals, the surface properties of gold minerals are changed, making it easier to form adsorption with collectors, thereby improving the gold particle flotation rate. A common gold flotation activator is copper sulfate.

Gold ore flotation inhibitors refer to chemical substances that can inhibit the flotation of specific minerals. Inhibitors hinder the adsorption of collectors by chemically reacting with the surface of certain minerals, making these minerals less likely to be adsorbed and floated by collectors. In this way, the gold particles can be more easily adsorbed and floated with the collector, achieving separation from other minerals. Common gold flotation inhibitors are nitrate and iron sulfide.

In gold ore flotation, the ore is usually finely ground into fine particles and mixed with water to form a flotation slurry. These ore particles are easy to coalesce together in the slurry to form agglomerates, which affects the effect of flotation. The use of dispersant can evenly disperse ore particles in the slurry, prevent agglomeration, and maintain the stability and high efficiency of the flotation process. Common gold ore flotation dispersants mainly include: polyacrylamide, carboxymethyl cellulose and silicate.

The above-mentioned agents are commonly used in the gold flotation process. In actual production, these agents need to be combined, and the dosage, time and frequency of addition should be strictly controlled. The specific agent addition operation should be based on the characteristics of the ore, the recovery rate of gold ore required by production and the specific process conditions of the flotation process. A reasonable reagent system can optimize the current flotation process, improve the recovery rate of gold concentrate, and increase economic benefits. Xinhai Mining suggested to conduct gold ore beneficiation test to determine the ore composition and characteristics, so as to determine the appropriate gold ore flotation process and gold ore flotation agent system, and avoid the cost increase caused by the waste of agents.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.