solutions

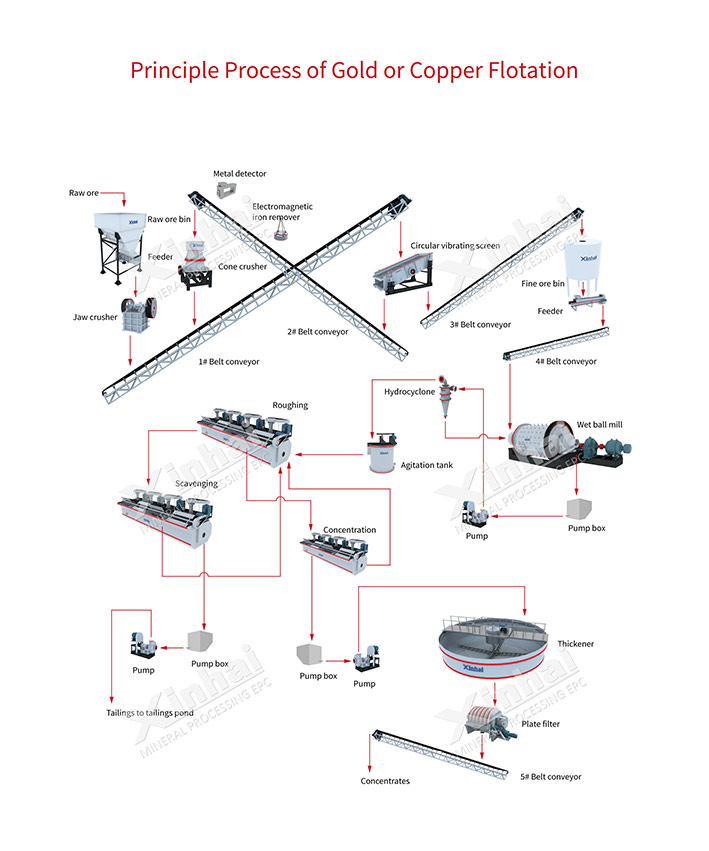

[Introduction]: Float mining is the core of a gold flotation production line, efficiently separating gold-bearing sulfide minerals from gangue. Fine gold and sulfide-associated gold are concentrated, while tailings are safely discharged, ensuring high recovery with low costs.

[Improvement]: Gold Flotation Process is used to process fine gold, sulfide gold-containing quartz ore, multi-metal gold-containing sulfide ore, and carbon-containing ore.

Gold mineral flotation normally adopts one stage grinding-flotation process, but stages grinding and flotation for ore with uneven distribution.

For the gold wrapped in sulfide minerals, sulfide ore reaches monomer dissociation; but for the gold with gangue, grinding fineness should reach gold monomer dissociation. The grinding fineness of minerals is determined by a test.

Flotation for large density and coarse particle needs thick pulp, whereas for small density and fine particle, needs dilute pulp.

In addition to the grinding fineness, process conditions of gold flotation also include slurry concentration, reagent dosage, aeration quantity, and flotation time.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.