Concentrators usually apply flotation separation when processing gold ore. Because during the gold flotation process, the gold in the ore is enriched as much as possible in the sulfide minerals. The gold flotation process is often used to treat finer gold particles and gold-bearing sulfide ores with good floatability. In addition, there are many kinds of ores that can also be used in the flotation process, such as polymetallic gold-bearing sulfide ores, and carbonaceous ores. What is the gold flotation process?

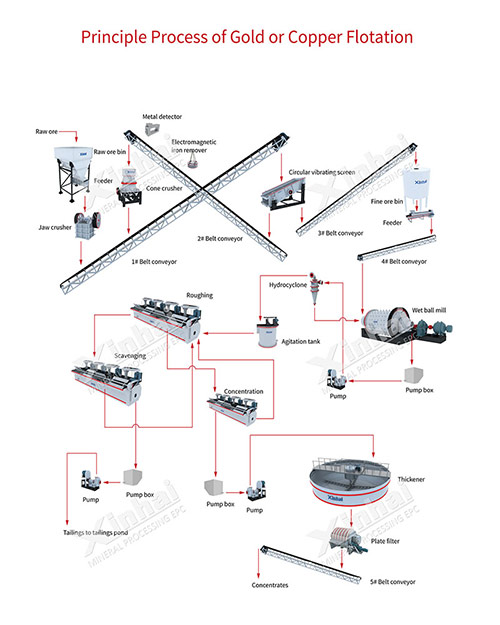

Generally, the gold flotation process can be divided into four stages, including crushing and screening process, grinding and classification process, flotation separation process, and concentration and filtration process. You can get the details of these processes from the following.

The gold ore stored in the raw material silo enters the jaw crusher through the trough feeder for coarse crushing. With the help of belt conveyor, the crushed products are transported by the belt conveyor to the vibrating screen for screening, and the under-screen products are the ores that can be ground. The products on the screen need to be transported back to the spring cone crusher for fine crushing. The ore processed by the crusher will be sent to the screening machine together with the ore discharged from the jaw crusher. Such a process constitutes a two-stage, one-closed-circuit crushing and screening process.

The crushed products will be sent to the powder silo via the belt conveyor for storage. During the grinding and classification process, the powder silo begins to discharge ores. These ores enter a wet ball mill for grinding through the feeder and the belt conveyor. The discharge ores pulp of the ball mill will be pumped into the hydrocyclone by the slurry pump for slurry classification. The overflow part of the hydrocyclone enters the next process flow. The remaining pulp from the classification needs to be returned to the ball mill for secondary grinding. In this way, there will form a closed-circuit grinding and classification process.

The pulp processed by the hydrocyclone is pumped into the agitation tank for dosing and pulping. The evenly stirred pulp is used for roughing operation. The coarse concentrate foams scraped by the scraper of flotation machine enter the next group of flotation machines for concentration operation. The slurry left in the flotation cell will be used for tailings scavenging. By doing so it can recover the gold concentrate as much as possible and reduce the waste of resources. After the sweeping operation, the pulp foams scraped by the scraper are sent to the previous flotation machine for re-selection. The remainder flows into the tailings pond for further process.

The concentrate ore pulp is pumped into the thickener by the slurry pump for concentration. During the concentration operation, the gold ore particles sink to the bottom of the thickener tank due to their own gravity overcoming the buoyancy. The gold ore particles deposited at the bottom of the tank are collected by the action of the rake at the discharge port at the bottom of the thickener and then discharged out of the machine. The concentrated products also need to be further dewatered by a disc filter device to become the final gold concentrate. During dehydration, the gold concentrate will adhere to the filter cloth of the filter, and then be scraped off by a scraper into the filter cake tank. Finally, these filtration products will be transported to the concentrate warehouse by belt conveyor for storage.

The above is the technological process of gold flotation. This process is mostly used in gold beneficiation plants. What should be noted is that for different types of gold ores, the treatment methods are different. For example, when dealing with ore containing single gold ore, coarse and evenly distributed gold ore, multiple grinding and flotation separation are not required. Generally , a grinding-floating process is used for this kind of ore.

In addition, during the gold flotation separation process, there are many factors that affect the flotation, including grinding fineness, pulp concentration, dosage of medicine, aeration amount of flotation cell machine, time and frequency of flotation, etc. Therefore, it is very important to choose the appropriate process flow and separation equipment. Xinhai has more than 20 years of experience in gold ore beneficiation process design and equipment production. What’s more, there are many successful cases of gold floating options for your reference in Xinhai. When looking for high-efficiency gold flotation process and equipment, choose Xinhai. We will customize the efficient gold flotation process and gold ore beneficiation equipment for you.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.