Lithium ore is the main raw material for energy development. It is widely used in batteries, electronics, chemicals, materials, medical and other fields. In recent years, as the main raw material for lithium battery production, its market demand is increasing. Therefore, lithium ore beneficiation technology has also been developed rapidly.

Different types of lithium ores have different properties, and the content of lithium oxide in the minerals is low and the mineral composition is different. Therefore, lithium ore beneficiation processes are also different. You can learn about several common lithium ore beneficiation processes and equipment from the following.

At present, the main lithium ore beneficiation processes include flotation separation, magnetic separation, gravity separation (or resuspension), manual separation, thermal crushing (cracking) and combined beneficiation.

Flotation separation is one of the main methods for lithium ore beneficiation. As long as the lithium mine has industrial value, the flotation separation process can be used, especially the lithium ore that exists in the form of fine-grained dissemination.

The flotation process of lithium ore is mainly affected by ore properties, grinding fineness, stirring operation, adjusting agent ratio and water hardness. For the pure mineral of lithium ore with uncontaminated surface, it is floated with oleic acid and its soap agent. The optimum pH in the flotation pulp is near neutral weak alkaline. Generally, before the flotation of lithium ore, Na2CO3 should be added to eliminate the influence of molten salt ions in the pulp and carry out stirring and desliming. And the surface of the lithium ore is scrubbed in the highly alkaline medium formed by adding NaOH (the recovery rate of lithium ore is determined by the amount of NaOH).

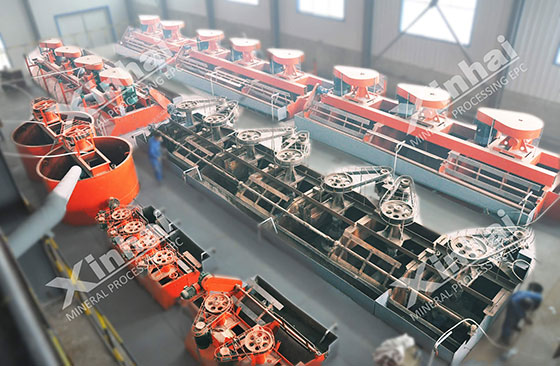

The equipment commonly used in lithium ore flotation technology includes: xcf flotation machine, kyf flotation machine, jjf flotation machine, sf flotation machine and coarse particle flotation machine. They can be used for roughing, sweeping and beneficiation of various large, medium and small lithium ore processing plants.

Magnetic separation of lithium ore is mainly used to remove iron-containing impurities in lithium concentrate. Generally, magnetite-bearing lithium ores are mainly lepidolite and lithium ore, which have weak magnetic properties. Therefore, iron-bearing minerals can be removed by strong magnetic separation technology to improve the grade of lithium ore. In the concentrator, magnetic separation is usually combined with flotation and gravity separation to form a combined beneficiation process.

Commonly used equipment for lithium ore magnetic separation technology includes: permanent magnet drum magnetic separator, high gradient magnetic separator, eccentrically arranged rotating magnetic field dry separator, etc. They can meet various wet environment and dry environment magnetic separation to select lithium concentrate.

Gravity separation is based on the density difference between lithium ore and gangue ore. This method is mostly used for the separation of lithium ore with coarse embedded particle size. Usually, when the density difference between lithium ore and gangue ore (quartz, feldspar, biotite, etc.) is more than 0.2-0.5g/cm3, shaker or jigging can be used.

When the density difference is less than 0.2~0.5g/cm3, the resuspension method can be used. The lithium minerals after washing and desliming are mixed with the heavy medium and fed into the heavy medium cyclone at a pressure of 0.05-0.20Mpa for sorting.

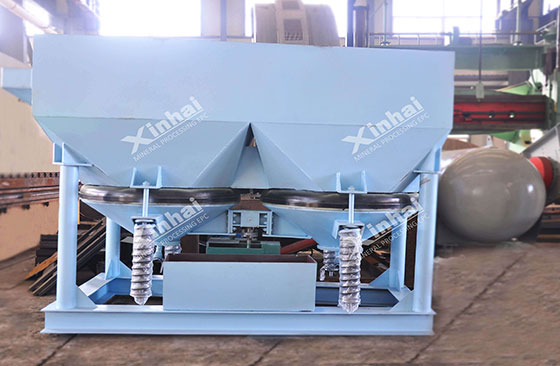

The equipment commonly used in lithium ore gravity separation technology includes: shaking table, jig, heavy medium cyclone, etc.

The manual separation process of lithium ore is mainly used to separate the raw ore containing more waste rock. In the concentrator, this method is mainly used as a pre-selection operation. In general, lithium ore is mostly silver-white, and there is a color difference with other impurity minerals. Therefore, sorting can be carried out by the difference in the surface properties between lithium ore and gangue minerals, so as to improve the selected grade of lithium ore. There is no need for better sites and equipment during beneficiation, and it only needs to be carried out on the hand-selected belt or on the hand-selected operating table.

Lithium ore thermal crushing method, also known as thermal cracking method, is selected by heating and cooling methods. This method is suitable for the treatment of lithium ores containing non-alcite, calcite and mica. Roasting at a certain high temperature converts lithium minerals from the original α-type to β-type lithium ore, while the gangue minerals remain unchanged, thereby obtaining lithium ore. The process is as follows: the ore is crushed to 50~20mm and then screened, the ore larger than 0.3mm is roasted at 1000~1200℃ for 1~2h, and then cooled and then selectively ground, classified and purified. Lithium ore smaller than 0.3mm can be extracted by combined separation technology.

The equipment commonly used in lithium ore thermal cracking technology includes: roasting equipment, ball mill, classifier, gravity separation equipment, flotation equipment, etc.

The combined beneficiation method is used to extract lithium minerals, which is mainly for the separation of poor and fine lithium minerals. When a single method fails to obtain qualified lithium concentrate, a combined method is required to obtain higher quality lithium concentrate. The main processes are: flotation-magnetic separation process, flotation-gravity separation-magnetic separation process, etc.

The above are several lithium ore beneficiation processes and used equipment. In addition, there is a chemical beneficiation method, which is mostly used to treat lithium minerals in salt lakes. Lithium is extracted from brine by precipitation method, extraction method, ion exchange adsorption method, carbonization method, calcination leaching method and electrodialysis method.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.