Many types of copper ores in the world contain molybdenum. Although the content of molybdenum in the ore is low, the comprehensive recovery value of molybdenum metal is relatively large, and most of the molybdenum metal is recovered from copper-molybdenum ores. Copper-molybdenum ores with copper as the main component and associated molybdenum are mainly porphyry copper deposits, and they are stored in large quantities in nature. They are currently an important resource for extracting copper and molybdenum in the world. Chalcopyrite is often the main mineral in porphyry copper, followed by chalcocite, and other copper minerals are rare. The molybdenum mineral associated with porphyry copper is mainly molybdenite. For the separation of this mineral, the concentrator generally chooses to use flotation process for processing. The following will introduce you to different flotation methods used for copper-molybdenum ore separation to help you better understand the beneficiation technology of copper-molybdenum ore.

Priority flotation process of copper-molybdenum ore can be divided into two types: first float molybdenum ore and then float copper ore, or first float copper ore and then float molybdenum ore. However, these two methods have a common technical difficulty: copper or molybdenum ore that has been suppressed by inhibitors is difficult to be activated again in the subsequent flotation process, thereby reducing the recovery rate. In addition, the design of the priority flotation process of copper-molybdenum ore is relatively complex, involving stage flotation and reagent addition, etc. These factors will increase the process cost. At the same time, due to the close symbiosis of copper and molybdenum ores in copper-molybdenum ore, flotation separation is difficult, and it is often difficult to achieve an ideal sorting effect. Therefore, this process is rarely used in actual ore dressing plants, and more economical and operational methods will be selected to treat copper-molybdenum ore resources.

When the grade of molybdenum ore in the copper-molybdenum ore is high, the partial mixed flotation process is generally selected as the treatment method. The characteristic of this process is that the molybdenum ore collector is first used to preferentially float out some easily floatable molybdenum to obtain part of the molybdenum concentrate, so that part of the molybdenum resources can be recovered in advance. Then the copper-molybdenum ore is mixed with the sulfide ore collector to obtain the copper-molybdenum ore mixed concentrate, and finally the mixed concentrate is separated from copper and molybdenum to further extract copper concentrate and molybdenum concentrate. This process effectively reduces the difficulty of subsequent copper-molybdenum separation by separating part of the molybdenum ore in advance, which can not only improve the flotation efficiency, but also reduce the cost of mineral processing.

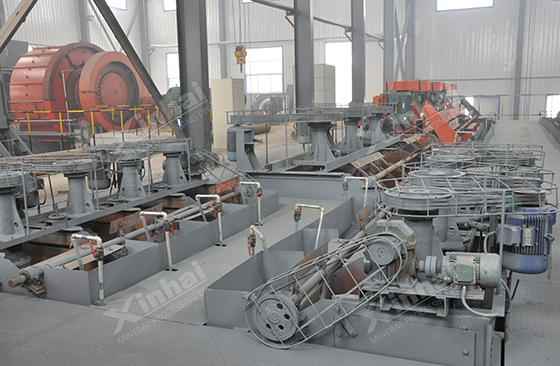

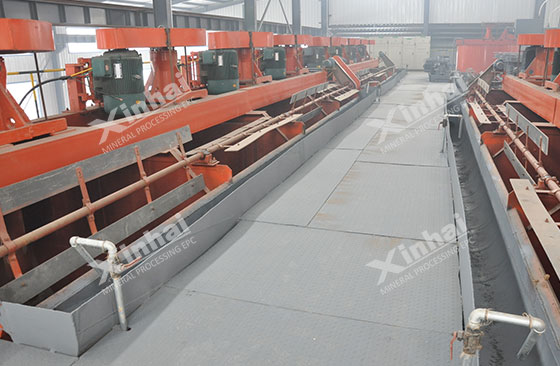

For the treatment of low-grade porphyry copper-molybdenum sulfide ores, it is generally chosen to first float the copper-molybdenum ore with a sulfide collector to obtain a mixed concentrate of the copper-molybdenum ore, and then separate the mixed concentrate. During mixed flotation, the copper should be floated as completely as possible, and the molybdenum should be floated into the copper concentrate. When the molybdenum content in the copper-molybdenum ore is too low, the copper-molybdenum ore cannot be effectively separated by flotation or the process cost is too high, the ore dressing plant generally chooses to only produce copper-molybdenum mixed concentrate. The advantage of separation after mixed flotation is that the grinding cost is low and the circulation of the middling ore is small. The entire flotation process is simple and easy to operate, and it is easy to implement on site. This process can effectively reduce the cost of copper-molybdenum ore flotation.

The above content is a brief introduction to the three flotation processes of copper-molybdenum ore. Since copper-molybdenum ore is a sulfide ore with good floatability, it only needs to add appropriate amounts of yellow medicine, black medicine, sulfide ore collector, etc. under appropriate conditions to achieve a higher flotation index of copper-molybdenum mixed concentrate. The mixed flotation re-separation process is often used in the beneficiation plant. Due to the uneven distribution of the embedded particle size of most copper-molybdenum ores, and the close coexistence of copper and molybdenum, it is difficult to completely resolve the collector after mixed flotation, which makes it difficult to separate copper and molybdenum.

In addition, the ore properties of different mining areas vary greatly, such as the type of gangue minerals in copper-molybdenum ore, the degree of mineral oxidation, and the content of associated elements in the ore, which also puts forward higher requirements for the selection of flotation process and the optimization of reagent system. Therefore, according to the specific characteristics and economic indicators of the ore, the formulation of a suitable copper-molybdenum ore flotation process can greatly improve the utilization efficiency of ore resources, and can also reduce the beneficiation cost and improve the separation effect, so as to better serve the mining production practice.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.