Lead-zinc ore is an important nonferrous metal mineral resource. It plays an important role in the national economy and is widely used in electrical, mechanical, military, metallurgical, chemical and other fields. After years of development, the reserves of lead-zinc resources have been significantly reduced. The shortage of raw materials in mines will restrict the sustainable development of the lead-zinc industry. In lead-zinc production mines, there are still a large number of low-grade and difficult-to-select ores that have not been utilized. Therefore, these ores need to be fully developed to meet industrial needs. At present, lead-zinc oxide ore and lead-zinc sulfide ore are the main minerals of lead-zinc industrial minerals. The following will introduce the flotation technology and reagents of these two types of lead-zinc ores.

Sulfide lead-zinc ore has industrial application value, and the main ones are galena (PbS) and sphalerite (ZnS).

The surface of galena is hydrophobic, and the unoxidized galena has been floated, and the floatability of oxidized galena will decrease. During flotation, the typical collectors of galena are xanthate and black medicine. Xanthate can be chemically adsorbed on the surface of galena, while butyl ammonium black medicine has a selective collection effect on galena. The galena inhibitor uses dichromate, but the inhibitory effect on galena activated by copper ions will decrease. Sulfur dioxide, sulfites, lime and other agents can also be used to inhibit the flotation of galena.

Sphalerite is a sulfide mineral that is difficult to float. The common types are mainly black or yellow sphalerite. When potassium permanganate is in an appropriate range, it can have a strong inhibitory effect on sphalerite. Cyanide, zinc sulfate, sulfites and other agents are used to inhibit the flotation of sphalerite.

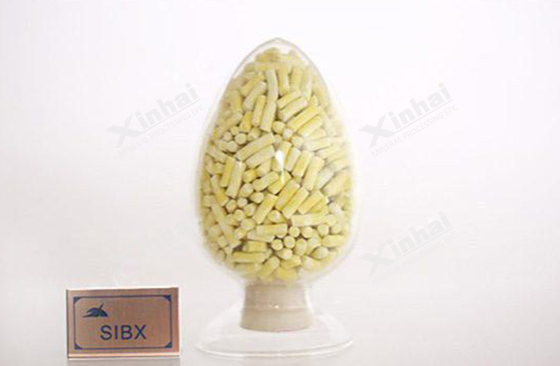

(1) Xanthate: Xanthate and xanthate esters are mainly used to collect lead-zinc sulfide.

(2) Ethyl sulfide: Ethyl sulfide nitrogen has a strong ability to collect pyrite and chalcopyrite, but a weak ability to collect pyrite.

(3) Black medicine: Black medicine is a good collector for sulfide ores and has certain foaming properties. Common black medicines include No. 25 black medicine, butyl ammonium black medicine, amine black medicine, etc.

(4) Lime: In copper, lead and zinc sulfide ores, iron sulfide ores are often associated. Adding lime can inhibit iron sulfide minerals, but it will increase the pH of the slurry and affect the foaming properties of pine oil. In addition, lime also has a certain coagulation property, which affects the flotation effect.

(5) Cyanide: Under alkaline conditions, this reagent has a good inhibitory effect on lead and zinc.

(6) Zinc sulfate: Zinc sulfate has a good inhibitory effect on sphalerite under alkaline conditions. When zinc sulfate is used alone, the inhibitory effect is poor and needs to be used in combination with cyanide, sodium sulfide, etc.

(7) Sulfurous acid, sulfite, SO2 gas, the actual effect is HSO3-, which is mainly used to inhibit pyrite and sphalerite. The inhibited sphalerite can be activated by adding CuSO4.

The main oxidized lead ores with industrial significance are cerussite and lead alum.

Cerussite is formed by the oxidation of galena into lead alum and then the action of carbonate aqueous solution. It is mainly produced in the oxidation zone of lead-zinc deposits. White lead ore is mainly white and colorless, and often coexists with ores such as calcite, barite, galena, lead alum and molybdenum.

Lead oxide minerals are easy to sulfide. When they are treated, they need to be sulfided and then collected with xanthate or black medicine. Since the ore mud will affect the flotation effect, it is necessary to desludging or add dispersants such as water glass before sulfidation to reduce the influence of ore mud.

The types of zinc oxide minerals include smithsonite and hemimorphite. When they are treated, the zinc oxide surface will form a colloidal precipitation of zinc sulfide by heating and sulfiding, and then it will be activated with copper sulfate and added with xanthate for flotation. Since the ore mud will seriously affect the effect of amine reagents and reduce the flotation index, it is necessary to pre-de-sludge or use dispersants to reduce the influence of ore mud.

(1) Vulcanizing agent, usually using sodium sulfide or sodium sulfide to vulcanize lead-zinc ore and then collect it with xanthate

(2) Collecting agents, fatty amine salts or oil-soluble salts are used to collect zinc oxide ores

(3) Inhibitors. The most selective inhibitors for gangue are tripolyphosphate, polyhydroxy acid, methanol carbonate guar gum and ethyl hydroxy starch. Calcium lignosulfonate is effective against common gangue minerals calcite and quartz. It is also highly inhibitory.

(4) Other reports include using sodium humate and colloid as dispersants, ethylenediamine having an activation effect on smithsonite, and methyl, ethyl, butyl dithiocarbonate on hemimorphite amine. Flotation method has significant activation effect.

In summary, the selection process of sulfide lead-zinc ore and oxide lead-zinc ore requires not only a deep understanding of the ore properties and its process adaptability, but also the introduction of modern beneficiation equipment and advanced beneficiation reagents in the process of continuous development and optimization. Future research and practice should pay more attention to energy conservation and environmental protection, improving resource utilization and reducing production costs. Through diversified beneficiation technical means and their combined application, the challenges of complex ore selection can be more effectively addressed, and the recovery rate and economic benefits of lead-zinc resources can be further improved. Only by continuous innovation and improvement of beneficiation technology can the sustainable development and utilization of lead-zinc ore resources be ensured, laying a solid foundation for the healthy development of related industries.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.