With the increasing popularization of the concept of carbon neutrality and new energy technologies, more and more attention has been paid to the development and utilization of cobalt mineral resources. In nature, most cobalt minerals are symbiotic with iron, copper, nickel and other metal minerals, and a single cobalt mineral is relatively rare. Common cobalt-containing metal deposits include copper-nickel-cobalt deposits, copper-cobalt deposits, iron and cobalt deposits and cobalt soil deposits. This paper will tell you about the beneficiation process of common cobalt deposits from the perspective of these four types of deposits.

In the copper-nickel-cobalt deposit, the main metal minerals are copper, cobalt, nickel, etc., the main gangue minerals are quartz, dolite, biotite, clinchioclase, serpentine, etc., and there are many kinds of sulfide minerals. At the same time, copper, nickel and cobalt are closely related to arsenic minerals, and there are more independent minerals of arsenic.

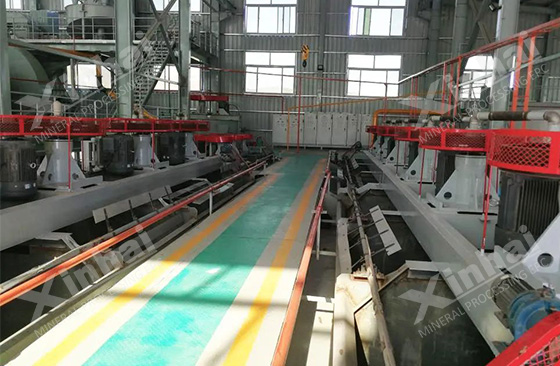

Copper-nickel-cobalt mineral is generally treated by mixed flotation process, and obtains copper-cobalt-nickel mixed concentrate with relatively large enrichment, which can be priced and sold at the same time or smelting treatment. It is important to note that the ore contains more floating gangue minerals, and in the process of grinding to produce secondary ore mud, affect the enrichment of copper nickel cobalt concentrate, can choose flocculation sludge-mixed flotation process, first mixed flotation enrichment is high copper nickel cobalt concentrate, then by hydrometallurgy separation extraction of cobalt minerals.

There are two kinds of copper and cobalt deposits, one often contains copper, lead, zinc, silver and other polymetallic minerals, and the other contains copper, cobalt, uranium and other minerals. The two deposits are different in the selection process, most of which are determined according to the floating difference of copper and cobalt minerals, generally including priority flotation process and mixed flotation process.

When the priority flotation process is used to treat copper and cobalt ore, it is generally preferred, lime is used as inhibitor, YK 1-11 is used as copper collector, and butyl yellow is used as cobalt collector, copper concentrate and cobalt sulfur concentrate can be obtained respectively.

When using the mixed flotation process to separate the copper and cobalt ore, butyl yellow drug can be used as the collector, and BKNL can be used as the adjustment agent for flotation to obtain copper and cobalt mixed crude concentrate. In the process, inhibitors such as water glass and lime are added to the selection to inhibit gangue minerals, and copper-cobalt mixed concentrate is obtained.

Iron and cobalt deposits generally contain cobalt minerals are pyrite, magnetite and a small amount of chalcopyrite, the main gangue minerals are quartz, attempt, chloridite, biotite, chlorite, etc., the components are more complex. Cobalt minerals are generally closely associated with iron minerals.

This kind of ore can be processed by flotation process. First, the sulfide and magnetite can be separated, and then a small amount of chalcopyrite, pyrite and pyrrhotite can be separated by flotation. At the same time, the magnetite can be separated by magnetic separation, and can get copper concentrate, cobalt sulfur concentrate and iron concentrate respectively.

Cobalt soil ore mostly produces from weathered deposits. In addition to cobalt, it also contains manganese, copper, nickel, iron and other metal elements. The recoverable part of the ore is often the complex formed by manganese oxide and cobalt oxide. Cobalt minerals are closely related to manganese minerals, containing more clay, iron ore mud and limonite. Generally, manganese minerals and cobalt minerals are recycled together.

In terms of beneficiation method, cobalt soil ore can choose a single or combined beneficiation process. The single beneficiation method includes gravity separation, magnetic separation, flotation separation, acid leaching, etc. The combined beneficiation method includes roasting-flotation and acid leaching-flotation, among which acid leaching-flotation is the most common beneficiation method of cobalt soil ore.

The above is about the mineral processing process of common cobalt mineral processing. The mineral composition of cobalt is complex, so the comprehensive recovery and utilization of different mineral resources should be considered when formulating mineral processing plans. Therefore, in the actual production, according to the different types and components of cobalt-containing ore, there are also differences in mineral processing process. The component properties of cobalt deposits should be analyzed first, and the scientific and reasonable mineral processing process scheme should be determined through tests, so as to avoid economic loss and resource waste caused by improper process schemes.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.