Build a manganese concentration plant can improve the utilization rate of manganese ore resources and meet the market demand for manganese concentrate. Manganese ore can be processed into manganese concentrate, which is widely used in steelmaking, batteries, chemicals, and other fields. Global environmental protection requirements for manganese plants are becoming increasingly stringent. Therefore, the construction of a manganese plant must take many factors into account. Its core goal is to achieve efficient, environmentally friendly, and cost-effective manganese ore beneficiation and processing.

1. Resource Assessment and Feasibility Analysis

In the early stages of building a manganese concentrator, the manganese ore resources should be evaluated. First, the quality of the manganese ore should be analyzed, including the grade of the raw ore, mineral composition (such as manganese oxide or manganese carbonate), and impurity content. Then, the manganese ore reserves and mining conditions should be assessed, including the scale of the ore body, burial depth, and the mining method to be adopted — either open-pit mining or underground mining.

A feasibility analysis report should be prepared based on the above evaluation results. The report should include technical feasibility, economic benefit forecasts, and the investment payback period.

2. Site Selection and Environmental Impact Assessment

The site selection for a manganese concentrator is particularly important. To reduce transportation costs, it is recommended to build the plant close to the mining area. Natural conditions such as geology, hydrology, and meteorology must be fully considered, along with the provision of essential infrastructure, including transportation, power supply, and water supply and drainage systems.

An Environmental Impact Assessment (EIA) must be conducted to determine wastewater and waste residue treatment plans and to formulate ecological protection measures. In addition, it is necessary to obtain permits such as mining licenses, land-use approvals, and EIA approvals.

1. Beneficiation Test and Process Design

The first step is to conduct beneficiation tests on the manganese ore, which include ore sampling and preparation, studies of the ore’s physical and chemical properties, and process flow testing.

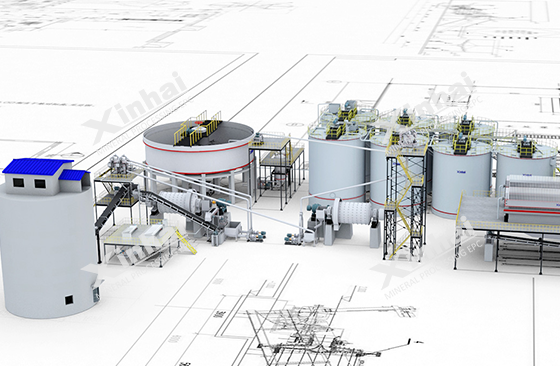

Following the test results and site planning, the process flow and equipment layout for the manganese concentrator are designed. Common manganese ore beneficiation methods include gravity separation (using jigs and shaking tables), magnetic separation (either strong or weak magnetic separation), leaching, and roasting reduction. However, it is difficult to achieve ideal impurity removal and manganese enrichment with a single beneficiation method. Therefore, most manganese beneficiation processes adopt a combined approach, such as "crushing–grinding–magnetic separation–gravity separation."

2. Key Euipment Selection

Key Equipment

The key equipment includes: Crushing equipment(jaw crusher, cone crusher).Grinding equipment(ball mill, rod mill).Separation equipment(magnetic separator, flotation cells, spiral chute).Dewatering equipment(thickener, filter)

Equipment Selection Principles

Equipment models should be selected based on a comprehensive consideration of process design, site area, planned production capacity, and equipment handling capabilities.

3.Tailings Treatment and Automation Technology

To better implement environmental protection strategies, tailings produced after beneficiation must undergo dewatering treatment. A commonly used method is tailings dry stacking, which reduces the moisture content of the tailings using equipment such as thickeners, filter presses, and dewatering screens. For flotation tailings, special attention should be given to removing residual reagents. The final tailings should be transported to a tailings storage facility.

Modern manganese concentrators should make full use of automation technologies such as DCS control systems and AI monitoring systems. These technologies not only help reduce labor costs but also ensure real-time, accurate monitoring of each process stage.

1. Site Preparation

In the early stages of concentrator construction, comprehensive site leveling operations must be carried out. This is a critical prerequisite for the smooth progress of subsequent infrastructure development. The construction team should use heavy machinery such as bulldozers and excavators to perform earthwork balancing according to design specifications, clear surface vegetation and obstacles, and ensure that the site slope meets drainage requirements. For special geological areas, localized reinforcement may be necessary to form a flat, solid, and well-drained construction base.

2. Infrastructure Development

Simultaneously, necessary infrastructure construction should proceed, including standardized steel-structured beneficiation plants, raw material and finished product warehouses, administrative buildings equipped with modern office facilities, dormitory areas to meet employee living needs, and supporting amenities such as canteens and bathhouses.

3. Equipment Installation and Commissioning

A scientifically rigorous construction plan should be formulated for equipment installation, clearly defining timelines, resource allocation, and construction requirements for each stage. A comprehensive safety management system should be established, with dedicated safety officers supervising construction activities to ensure a safe, controlled, and high-quality installation process. After installation, equipment must undergo trial runs and commissioning to ensure smooth production startup.

1.Standard Operating Procedures (SOPs)

Strict SOPs should be established for production management, covering all stages such as ore crushing, grinding, separation, and dewatering. These procedures should define equipment operation parameters, maintenance schedules, and contingency plans for anomalies. Regular training and assessments must be conducted to ensure staff compliance with SOPs.

2.Quality Control

Dynamic monitoring of manganese concentrate grade is essential. Techniques such as X-ray fluorescence spectroscopy (XRF) or chemical analysis should be used to test manganese content and impurities (such as iron, silicon, and phosphorus). Based on test results, process parameters (such as magnetic separation intensity and reagent dosage) should be optimized to ensure the concentrate meets contract requirements (typically Mn ≥ 30%). A quality traceability system should be established to analyze the causes of nonconforming products and provide feedback to the production line, forming a closed-loop management system.

Conclusion

The above outlines the construction process of a manganese concentrator and its operational management after commissioning.

Xinhai Mineral Processing offers a full industry chain service (EPC+M+O) for mining, plant construction, equipment manufacturing and installation, and plant operation.

If you are planning to build a manganese concentration plant, partner with Xinhai to ensure efficient, reliable, and profitable project success. Contact us today to start your journey!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.