products

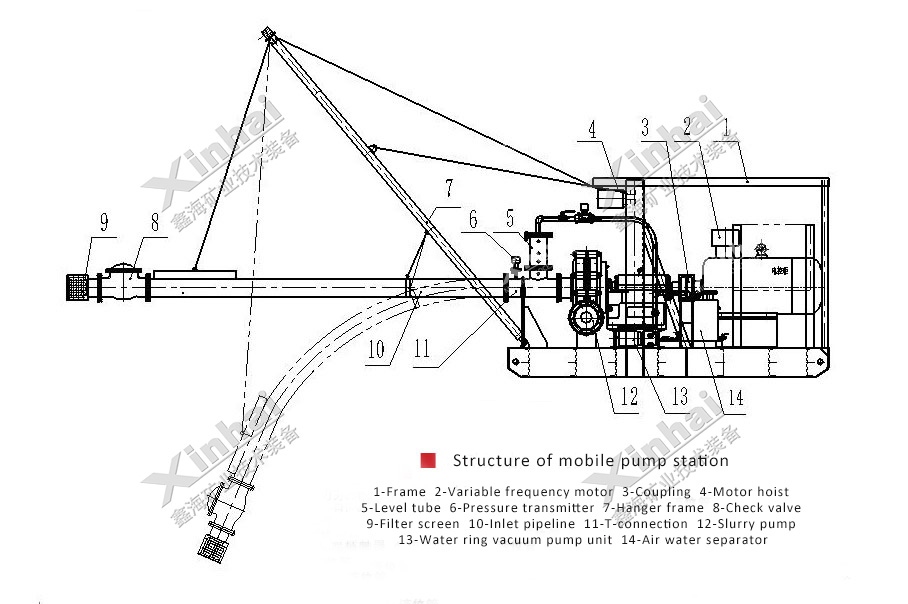

[Introduction]: A kind of mobile conveying equipment for fluid substances with high level of modular and automation.

[Capacity]: The flow rate ≤2333 m³/h

[Improvement]: Xinhai mobile pump station realizes four core functions: automatic drainage, automatic monitoring of equipment operation, automatic control of equipment start and stop, flexible and easy to move.

The vacuum drainage system is a drainage system assisted by a vacuum pump.The vacuum drainage system is divided into two parts: one is the water supply pump and pipeline; Another part is the vacuum pump, air-water separator and auxiliary pipeline.

The vacuum system can realize the functions of vacuum pumping and vacuum holding, solve the exhaust and drainage procedure before the pump starts, and realize the starting of the water supply pump conveniently, momentarily and fast. The vacuum pump and auxiliary pipeline are composed of a vacuum pump,gas-water separator, gas-water separator filling water pipeline, control cabinet, connecting pipeline and instrument valve. Before starting the feed pump, the gas in the inlet pipe, feed pump and outlet pipe are extracted through the exhaust outlet of the water pump. The gas enters the vacuum pump firstly, then enters the gas-water separator under the action of the vacuum pump, and finally is discharged into the atmosphere. After the water diversion is completed, the feed pump can be started at any time. During the operation,start the vacuum pump when the vacuum degree is lower than the minimum value,and stop it after the vacuum degree is pumping to the highest value.

| Model of mobile pump station | Flow rate (m3/h) | Head(m) | Rotate speed(rpm) | Model of slurry pump | Model of vacuum pump |

| YB-50 | 12-111 | 7.7-110.7 | 700-1480 | 50ZJ-I | 2BVA2060 |

| YB-80 | 43-242 | 8-109.8 | 700-1480 | 80ZJ-I | 2BVA2070 |

| YB-100 | 56-360 | 8.2-100.2 | 700-1480 | 100ZJ-I | 2BVA2070 |

| YB-150 | 95-550 | 8.7-100.2 | 700-1480 | 150ZJ-I | 2BVA2070 |

| YB-200 | 199-978 | 13-133.7 | 490-980 | 200ZJ-I | 2BVA5110 |

| YB-250 | 276-1573 | 13.1-133.7 | 490-980 | 250ZJ-I | 2BVA5110 |

| YB-300 | 395-2333 | 9.7-79.9 | 400-590 | 300ZJ-I | 2BVA5110 |

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.