Fluorite ore is a valuable mineral used extensively in a variety of industrial applications. In order to make full use of this resource, it is crucial to refine the fluorspar ore and obtain high-quality fluorspar concentrate. In this article, we’ll take a deep dive into the world of fluorspar ore flotation, discussing techniques, reagents, and ways to remove pesky iron ore impurities.

Flotation is a commonly used method for fluorite ore separation. It is mainly used to separate fluorite ore from other impurities, especially iron-containing impurities. The flotation process mainly relies on the hydrophilic nature of fluorite ore. By adding a certain flotation agent, the fluorite ore particles can interact with the bubbles and attach to the bubbles, and then float to the liquid surface. Impurity minerals remain in the flotation equipment.

(flotation equipment)

The commonly used equipment and reagents in the flotation process are mainly flotation machines, stirring tanks, chemical stirring tanks, and concentration and dehydration equipment.

The flotation machine is the core of the flotation process. Different types of flotation equipment can be selected according to different ore types. The main types of flotation equipment are: mechanical stirring, inflatable and flotation.

Stirring tank and chemical mixing tank: mainly used for stirring slurry, mixing slurry and chemicals, etc. to ensure sufficient reaction between chemicals and ore particles.

Concentration and dehydration equipment: It is to further dehydrate the flotation concentrate and remove excess water. Thickeners, filters, filter presses and other equipment are often used.

Flotation agents play a vital role in the process of separating fluorspar from other minerals. Correct selection and dosage of chemicals are critical to a successful flotation process. The two main types of agents commonly used are:

(Collector)

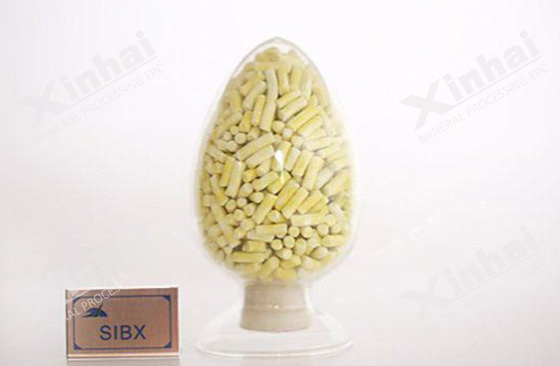

Collector: These chemicals attach to the surface of fluorite particles, making them hydrophobic. Common collectors used for fluorspar include fatty acids, flavonates, and phosphates.

Fatty acid: Fatty acid is one of the commonly used collectors in fluorite flotation. In particular, fatty acids such as palmitic acid, oleic acid and stearic acid show good collection performance in fluorspar flotation.

Flavonates: Flavonates, such as flavones, flavonic acids and flavonates, can also be used as collectors for fluorite.

Phosphates: Certain phosphate compounds, such as esters and phosphates, can be used to increase the hydrophilicity of fluorspar particles, allowing for effective flotation.

Foaming agents stabilize foam and improve bubble formation. Examples of frothers used in fluorspar flotation include rosin oil and methyl isobutyl carbonate (MIBC).

Rosin oil: Rosin oil is a commonly used foaming agent that helps maintain foam stability and improves bubble formation.

Methyl Isobutyl Carbonol (MIBC): MIBC is another widely used foaming agent, often used to enhance bubble stability.

Ethanol: Ethanol can also be used as a frother, especially in the flotation of certain fluorspar ores.

Selection of the appropriate flotation agent usually depends on the characteristics of the fluorite ore, including its mineral composition, the hydrophilicity and lipophilicity of the ore minerals, and the desired separation efficiency. Different ores may require different types and combinations of agents to achieve good flotation results. Therefore, when performing fluorite ore flotation, it is usually necessary to conduct mineral processing experiments and process optimization to determine the appropriate chemical combination.

Removing iron impurities from fluorspar ore is key to obtaining a high quality concentrate, the following are the steps typically involved:

First, the particle size of the ore is reduced and ground into a fine powder to expose iron ore impurities. Fluorite is separated from iron-containing minerals using a flotation process. Adjust process parameters and reagents to achieve selective flotation. After flotation, the concentrate may still contain residual iron. Magnetic separation can be used to further reduce the iron content, attracting and separating the iron-bearing minerals in the fluorspar concentrate. In some cases, gravity separation techniques can be used to remove any remaining iron-containing minerals from the concentrate. Throughout the process, concentrate samples are analyzed regularly to ensure the iron content meets the required specifications. Adjust as needed.

(flotation process)

The above are the flotation technology, equipment, chemicals and iron removal technology in the fluorite ore beneficiation process. Depending on the nature of the ore, flotation technology, equipment, mineral processing reagents and iron removal technology need to be appropriately adjusted. In order to improve the beneficiation efficiency of fluorspar ore, a beneficiation test can be conducted to determine the composition of the ore, and then determine a suitable fluorspar ore beneficiation plan according to production requirements to improve the production efficiency of fluorspar ore.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.