solutions

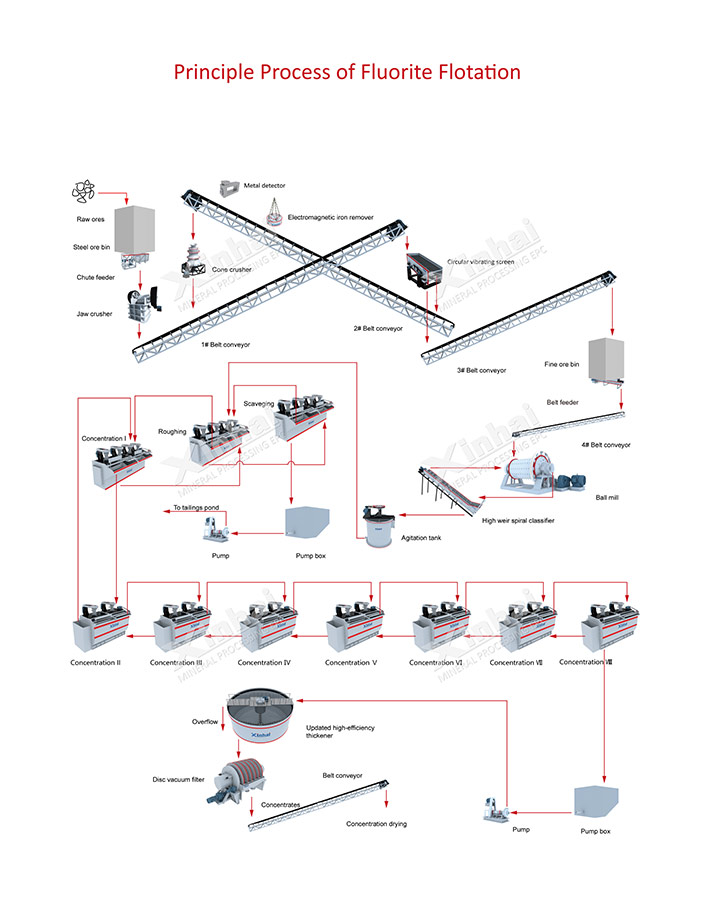

[Introduction]: Process methods of fluorite ore are gravity separation and flotation. Mineral processing equipment includes gravity separation equipment and flotation equipment; Gravity separation equipment: jig, only jig can deal with the coarse fluorite ore. Fluorite flotation equipment is similar with other mineral flotation equipment including crusher, ball mill, flotation machine etc..

[Improvement]: Fluorite flotation process is applied for refractory fluorite with complicated properties such as high mud content, impurity containing, fine particle distribution, etc..

The sulfide ore contained in fluorite is floated with xanthate collector, and then fatty acid collectors float fluorite. In flotation of fluorite, it can be also feasible to add a small amount of sulfide mineral to inhibit residual sulfide mineral, and ensures the quality of fluorite concentrate.

Mixed flotation of fluorite and barite flotation, and then separate them. In mixed flotation, obtain mixed concentrate with oleic acid as collector. Mixed concentrate separation can use positive or reverse flotation to obtain fluorite concentrate.

The fatty acid collects fluorite, and sodium silicate restrains quartz. The dosage of sodium silicate should be controlled properly; a small amount has activation to the fluorite, but inhibition function is not enough; excessive inhibits fluorite. Sometimes in order to increase the inhibitory effect of sodium silicate on quartz, some multivalent metal ions will be add.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.