Copper, lead and zinc are three important nonferrous metals, and all of them are sulfur-loving elements. They often exist in the form of sulfides in the earth's crust. Copper, lead and zinc minerals come from the sulfide ore oxidation zone, which is the product of complex weathering (physical, chemical and biological effects) after the sulfide deposits are exposed to the surface.

Copper, lead and zinc often exist in a symbiotic relationship, and the relationship between minerals is complex, making separation difficult. In terms of ore separation methods, flotation is mainly used to achieve separation. Let's introduce the flotation process of copper oxide, lead oxide and zinc oxide respectively.

The main copper-containing minerals in oxidized copper ore include malachite, azurite, cuprite, etc. These minerals usually exist in the form of fine particles, films or soil. In addition to oxidized copper minerals, it may also contain other gangue minerals, such as quartz, feldspar, mica, calcite, etc. At present, the flotation of oxidized copper ore is divided into direct flotation and sulfide flotation.

The characteristic of direct flotation is that no activator is added, and the collector is directly added to float the copper mineral. This method can be divided into fatty acid flotation, amine flotation and emulsion flotation according to the difference in the properties of the collector used. However, this method has poor selectivity for the target mineral, which limits the application of direct flotation in the beneficiation of oxidized copper ore.

Fatty acid flotation: fatty acid collectors (such as oleic acid, linoleic acid, linolenic acid) are used to react with the surface of copper oxide minerals under certain pH conditions, making the mineral surface hydrophobic so that it can be captured by flotation bubbles, and it has a certain selectivity for copper oxide ores containing siliceous gangue.

Amine flotation: amine collectors (such as dodecylamine and octadecylamine) are used to combine with the surface of copper oxide minerals through electrostatic adsorption under acidic conditions, making the mineral surface hydrophobic, thereby achieving flotation.

Emulsion flotation: a water-insoluble oil (such as kerosene, diesel, etc.) is mixed with water and surfactants to form a stable emulsion. This emulsion is then added to the pulp of copper oxide ore. During the flotation process, the oil droplets in the emulsion will selectively adsorb on the surface of copper oxide minerals, making the mineral surface hydrophobic, so that it can be captured and floated by flotation bubbles.

When sulfidation flotation is used for copper oxide, it is necessary to add a sulfiding agent before adding a collector to sulfidate the copper oxide mineral, so that the surface of the difficult-to-float copper oxide is sulfided to form a copper sulfide film layer with good floatability. During the flotation process, the hydrophobic copper sulfide film formed by the sulfiding agent on the surface of the copper oxide mineral can adsorb the collector, so that the copper oxide mineral can be flotated and recovered. Depending on the sulfidation method, there are conventional sulfidation flotation, hydrothermal sulfidation flotation, heated sulfidation flotation, segmented sulfidation flotation, etc.

Conventional sulfidation flotation: first add an appropriate amount of sulfiding agent to the ore pulp, let the sulfiding agent react chemically with the surface of the copper oxide mineral, and form a sulfide film on the surface of the mineral, so that the surface properties of the copper oxide mineral are similar to those of the copper sulfide mineral. Then add conventional copper mineral collectors, such as xanthate and black medicine. The collector acts on the surface of the sulfided copper oxide mineral to make it hydrophobic, so that it can be captured and floated by the flotation bubbles.

Hydrothermal sulfidation flotation: refers to the method of using SO2 or sulfur powder as an activator for copper oxide minerals under hot pressure conditions to sulfidate the difficult-to-float copper oxide minerals into easily floatable copper sulfide minerals, and then using conventional copper sulfide collectors for flotation.

Heating sulfidation flotation: before or at the same time as adding sulfiding agents to sulfidate the copper oxide ore, the pulp is heated, and after heating sulfidation treatment, collectors are added for flotation.

Segmented sulfidation flotation: The sulfidation process is divided into multiple stages. In different stages, different sulfiding agent dosages, sulfidation times, and slurry conditions are controlled. For example, a small amount of sulfiding agent can be used for pre-sulfidation first, and then the main sulfidation can be carried out, or sulfidation treatment can be carried out separately in different flotation operations.

The main lead-containing minerals of lead oxide are cerussite, lead alum, etc. These minerals often appear in the form of blocks, granules or soil; gangue minerals include quartz, feldspar, mica, etc. In the actual production process, most concentrators use sulfide flotation to select lead oxide ores. This is mainly because lead oxide minerals are a relatively soluble mineral. Therefore, a large amount of lead ions are released from the mineral lattice into the slurry solution, which will cause the mineral surface to be unstable, so it needs to be sulfided first.

Sulfidation usually uses sodium sulfide. When interacting with lead oxide minerals, the reactant is HS-, that is, after HS- in the slurry solution is adsorbed on the mineral surface, it undergoes an ion exchange reaction with the lead atoms on the mineral surface to generate a hydrophobic lead sulfide product, thereby activating the flotation of lead oxide minerals.

At present, the main methods for treating lead oxide ore are: sulfide-xanthate flotation, anion collector direct flotation, chelating agent-neutral oil flotation, leaching-flotation, etc.

Sulfide-xanthate flotation: adding sulfiding agent (sodium sulfide) to the lead oxide ore pulp, reacting with the mineral surface to form a lead sulfide film, and then reacting with the added xanthate to separate the mineral by flotation.

Anion collector direct flotation: directly using anion collectors (fatty acids, sulfonic acids, phosphonic acids, etc.) to chemically or physically adsorb metal ions on the surface of lead oxide minerals, making the mineral surface hydrophobic, thereby achieving flotation.

Chelating agent-neutral oil flotation: using chelating agents (such as 8-hydroxyquinoline, benzotriazole, etc.) to form stable chelates with metal ions on the surface of lead oxide minerals, and then adding neutral oil (kerosene, diesel, etc.) to make the mineral hydrophobic, thereby achieving flotation.

The main zinc-containing minerals of zinc oxide are smithsonite, hemimorphite, etc. These minerals mostly exist in the form of blocks, granules or fibers. Gangue minerals also include quartz, feldspar, mica, etc. Flotation process is the main method for zinc oxide selection. The most common ones are sulfide-amine flotation and sulfide-xanthate flotation. In addition, there are fatty acid direct flotation and flocculation flotation.

First, use a sulfiding agent (usually sodium sulfide) to pre-sulfurize the zinc oxide ore, and then use a fatty amine collector for selection. However, it is sensitive to ore mud and soluble salts, resulting in large reagent consumption and high selection costs. It is not suitable for processing ores containing a large amount of mica, chlorite, shale, sericite or carbonaceous shale, because these gangue minerals are easy to float with zinc oxide ore during the flotation process, thereby reducing the quality of zinc concentrate.

It is also necessary to pre-sulfurize the zinc oxide ore with sodium sulfide, then add copper sulfate for one-step activation, and then use advanced xanthate for collection. This method sometimes requires heating to obtain a better flotation effect, and the amount of copper sulfate used is large, the beneficiation cost is high, and it is difficult to apply in industry.

It is to use fatty acid collectors to directly select zinc oxide ore. Its main feature is that it has a good flotation effect for zinc oxide ore containing siliceous and muddy gangue. It is not suitable for processing zinc oxide ore containing carbonate gangue minerals and high iron content. The reason why this method has not been widely used in industry is that the collector selectivity is relatively low.

It is to add high molecular weight compounds during flotation, and selectively flocculate useful minerals or gangue minerals into small groups under specific medium conditions, and then add carboxylic acid collectors for flotation. It can process target minerals below 20μm. When using flocculation flotation method, the effective dispersion of useful components and gangue components should be solved first, and then the polymer selective flocculation method or selective hydrophobic aggregation method should be used for separation.

The above is an introduction to the flotation process of copper oxide ore, lead oxide ore and zinc oxide minerals. In actual ore dressing plants, since the three minerals often coexist and the properties of the ores are different, only through ore dressing tests and analysis and design of suitable flotation processes can ideal copper concentrate, lead concentrate and zinc concentrate be effectively obtained.

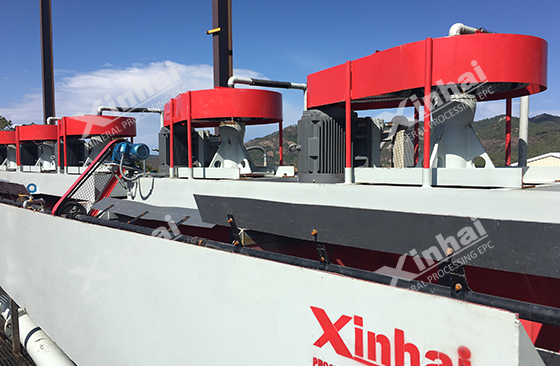

Xinhai Mining has rich experience in copper, lead and zinc beneficiation, and has many projects in progress or completed. If you have any needs, please feel free to consult. Xinhai can provide mining industry chain services (EPC+M+O).

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.