With the continuous development of industry, the demand for copper is increasing year by year. In order to meet production needs, making full use of copper resources is one of the main solutions. As the main copper resource, chalcopyrite is often associated with pyrrhotite, and the copper-sulfur separation efficiency is the main factor affecting the utilization rate of copper resources. Therefore, it is necessary to understand and optimize the flotation separation methods of chalcopyrite and pyrrhotite. This article will introduce you to the flotation technology of chalcopyrite and pyrrhotite from the following aspects: the floatability of chalcopyrite and pyrrhotite, the technical difficulties of flotation separation, flotation technology and flotation reagents.

Chalcopyrite is the main copper resource, and copper-sulfur symbiosis is a relatively common situation. Pyrrhotite-type pyrite is a common associated mineral of chalcopyrite. The content of pyrrhotite in the deposit affects the beneficiation index of chalcopyrite.

Chalcopyrite is one of the minerals with good floatability in nature, and its floatability is good under both auto-induced and collector-induced conditions. Different slurry pH values and slurry potentials have relatively little impact on chalcopyrite. In the priority flotation and mixed Duxuan process designs of polymetallic sulfide ores, chalcopyrite is a product recovered by idle flotation.

The floatability of pyrrhotite is related to its crystal structure. The floatability of hexagonal pyrrhotite is relatively poor, while the floatability of monoclinic pyrrhotite is relatively good within a wide pH range. Another factor that affects the floatability of pyrrhotite is that pyrrhotite is easily oxidized after exposure, and its oxidation rate is much faster than that of pyrite. Pyrrhotite avoids the hydrophilic layer of FeO(OH) and Fe(OH)2 generated by oxidation, which reduces floatability and consumes oxygen, which affects the collection effect of the collector.

The main metal minerals of high-iron copper-sulfur ores are chalcopyrite and pyrrhotite, and the gangue minerals are mainly quartz, calcite, feldspar, etc. Based on the process mineralogical analysis of high-iron copper-sulfur ores, the technical difficulties in the flotation separation of copper sulfide ores rich in pyrrhotite can be summarized as follows:

1. Due to the close relationship between chalcopyrite and pyrrhotite, the difference in their floatability is small, and it is difficult to achieve effective separation by conventional flotation methods.

2. The properties and floatability of pyrrhotite from different mineral deposits and different crystal systems vary greatly. Pyrrhotite in the hexagonal crystal system has poor floatability and magnetic properties, while pyrrhotite in the monoclinic crystal system has better floatability and magnetism. Most pyrrhotite in nature is a mixture of these two crystal systems, which makes it difficult to flotation recovery of pyrrhotite-type sulfur ores.

3. The monoclinic pyrrhotite has undergone magnetic agglomeration, which is not conducive to flotation.

4. Pyrrhotite is prone to oxidation. During oxidation, it consumes oxygen in the slurry, reduces the flotation potential in the slurry, worsens the flotation environment, and reduces floatability.

In the separation process of copper-sulfur ore, the flotation technologies used include: priority flotation, mixed flotation, mixed-priority flotation process, department priority-mixed flotation, and other flotation processes. For some difficult-to-select complex ores, the stage grinding stage separation-separate processing process of medium ore can also be adopted. For some minerals that are difficult to separate, a combined magnetic flotation process of sulfide ore mixed flotation and coarse concentrate regrinding and magnetic separation is used to obtain qualified copper concentrate. The flotation process for suppressing sulfur and floating copper is widely used. In actual production, the appropriate flotation process should be selected based on the properties of the ore.

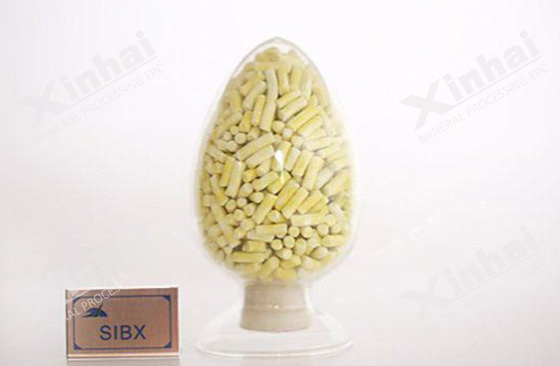

Chalcopyrite flotation collectors include xanthate, black drug, mercaptan, sulfur and nitrogen, thiamine ester and heterocyclic collectors. Among the xanthate collectors, butyl xanthate is the main one, followed by ethyl xanthate, amyl potassium xanthate, etc. The main collector of black drug is butylammonium, but its collection performance is weaker than that of xanthate, and its selectivity is better than that of xanthate. Therefore, a mixture of xanthate and black drug collectors will be used in production to take into account the collection performance and selectivity of Liuhu copper mine.

To separate chalcopyrite and pyrrhotite by flotation, in addition to a suitable collector, a suitable pyrrhotite inhibitor should also be selected. Pyrrhotite inhibitors mainly include high-base inhibitors, low-base inhibitors and microbial inhibitors. The high-alkali process is a commonly used method for separating copper-sulfur ores, and lime is a commonly used inhibitor for pyrite and pyrrhotite. Lime not only inhibits sulfur, but also adjusts the pH of the slurry. In order to lower the pH value of the slurry, lime is often used in combination with certain mail or stepless inhibitors, such as sodium sulfide, sodium sulfite, potassium permanganate, etc. Selecting an appropriate inhibitor combination based on the different properties of copper-sulfur ores can effectively inhibit the emergence of sulfur minerals. Microbial beneficiation is a relatively clean mineral beneficiation method. Certain microorganisms can be used as inhibitors of some minerals to reduce the floatability of minerals. The principle is that special groups on the outer membrane of bacteria have selective adsorption on minerals, making the mineral surface hydrophilic. And be suppressed.

The above content is about the four aspects of flotation technology of chalcopyrite and pyrrhotite. In actual production, the design of the flotation process for chalcopyrite and pyrrhotite should be based on the ore characteristics and production requirements. Xinhai Mining recommends conducting mineral processing tests to determine the characteristics of copper minerals in order to formulate appropriate flotation processes and select appropriate flotation equipment to improve the utilization rate of copper ore resources and the recovery rate of concentrates.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.