In 2023, we continued to work hard, forge ahead, and enter the new year with solid steps. Looking back 2023, let us witness together the results of some of Xinhai Mining's projects in 2023.

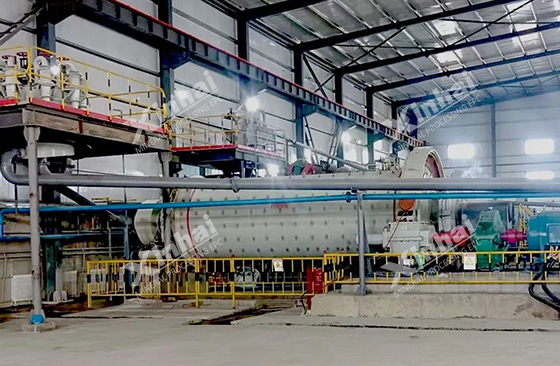

Xinhai Mining signed a 2 million TPA spodumene ore processing project contract with Sinomine Resources in Zimbabwe and is responsible for the design and construction of the Zimbabwe lithium mine project. It provides the project with EPC+M+O Services including process design and research, equipment manufacturing and procurement, plant civil engineering and installation, mine management and operations.

Xinhai Mining attaches great importance to this project. The entire project team coordinated and produced a total of approximately 170 million pieces within three months. It also formulated a strict construction schedule and mobilized a large number of professional and technical personnel to the project site. Professional and institutionalized services ensured that the project reached production standards and production within the agreed one-year period.

This project is one of Xinhai Mining's key projects in 2023. Xinhai Mining provides overall EPC+M+O Services from design to installation and commissioning. The main ores of this project are titanium ore and zircon, and the process flow is relatively complex.

Xinhai Mining adopts innovative thinking based on its rich design experience to formulate innovative recovery technical solutions for comprehensive mineral recovery. It repeatedly conducts mineral processing tests and technical discussions. In addition to recovering ilmenite and zirconium ore, it also comprehensively recovers monazite and rutile. and other useful minerals, and comprehensively recovered fracturing sand from the remaining materials, leaving only 0.2% iron-containing silicate minerals, meeting customer's demand and realizing comprehensive recovery of raw materials.

The source of the ore raw materials for this project is complex, including powder ore and lump ore, with an average raw ore grade of about 1.5. Xinhai provided mine design and main equipment for the project.

According to the nature and status of the raw ore, Xinhai Mining designed the grinding-magnetic separation-desliming-flotation-concentrate dehydration-tailings classified dehydration process. After trial operation and production, the indicators can meet customer production needs.

Entrusted by the project company, Xinhai Mining provided equipment manufacturing and procurement, installation and commissioning and other services for the Hubei 900,000 TPA quartz sand processing plant project.

The product plan of the project is secondary flat glass sand, and the main process flow is scrubbing-grading-scrubbing-classifying-magnetic separation. The project has been installed and is in the process debugging stage. It has produced the first batch of qualified products with SiO2 grade of 96.5%, Al2O3 grade of 2.05% and Fe2O3 grade of 0.09%.

According to the commissioning requirements of the project, Xinhai Mining has built a new 3000t/d gold mine CIP plant for the project. It uses advanced and reliable process technology and large-scale and efficient mineral processing equipment to save investment as much as possible. After debugging, it has reached the standard and reached production. , to meet customer expectations.

Local gold deposits are divided into two industrial types, one is surface laterite type ore, and the other is quartz vein type ore in weathered rock and semi-weathered original rock below the laterite layer. Laterite type ore body is an unconsolidated gold-bearing ore body. Laterite, consolidated calcareous rock, calcareous conglomerate, 80% of the ore is powdery clay ore, containing granular gold, gold is the only recoverable element, open-pit mining is used, because the ore is in the form of sand powder. According to the characteristics of the ore and the environment where the project is located, Xinhai Mining designed a process flow of one stage of open circuit crushing - one stage of closed circuit grinding and classification - leaching adsorption - desorption and electrolysis.

Xinhai Mining impressed the customer with its thoughtful service and outstanding capabilities. The customer highly recognized Xinhai Mining's brand influence and service quality and chose Xinhai Mining to provide services including the 800TPD fluorite flotation plant project in Mongolia. Customized mining industry chain services including mineral processing test, mine design, complete equipment manufacturing and procurement, installation, commissioning and delivery.

The CaF2 content in the raw ore of this project is 42.10%, the SiO2 content is 43.43%, and the gangue minerals are mainly quartz, sericite, and dolomite. Fluorite minerals have a close symbiotic relationship with quartz minerals, and the particle size is relatively fine. Aluminum-containing minerals have a negative impact on flotation. Xinhai Mining determined the appropriate flotation process through mineral processing tests.

Xinhai Mining provides services including mine design and equipment customization for the Myanmar 500TPD gold mine project. According to the project characteristics and actual conditions, Xinhai Mining designs and customizes gold ore dressing plant equipment.

The metal minerals in the ore mainly include pyrite, sphalerite, pyrrhotite, ilmenite, chalcopyrite, with a small amount of natural gold, trace tellurite, etc. Non-metallic minerals mainly include quartz, plagioclase, chlorite, mica, dolomite, calcite, and a small amount of amphibole. Among the useful minerals, the main one is natural gold. Xinhai Mining designed a two-stage and a half closed-circuit crushing and screening-two-stage grinding and classification-leaching adsorption-desorption electrolysis process flow for this project. After commissioning and commissioning, it was successfully put into production and achieved good mineral processing indicators.

According to customer needs, Xinhai Mining has technical communication with customers and provides a complete gravity separation process design. The processing capacity can reach 600-800t/d, meeting the customer's expected needs. After the equipment arrives locally, Xinhai installation team arrived at the project site for installation guidance, and the recovery rate met expectations.

The project is one of the important dressing projects undertaken by Xinhai Mining. Xinhai will provide customized mining industry chain services for the project, including research and design, complete equipment manufacturing and procurement, commissioning and delivery, project management, and the use of professional and mature mineral processing technology and processes to build high-standard green mines.

During the service period, Xinhai Mining's team overcame various adverse conditions, stuck to their posts, did corresponding work well, and impressed the customer with their down-to-earth and orderly spirit. The customer therefore wrote a letter to express his gratitude. The project has now been put into operation.

Xinhai Mining provides the project with full mining industry chain services, including mineral processing testing, construction drawing design, process flow formulation, full set of equipment manufacturing, installation and commissioning, and worker training.

The main metallic mineral in this project is magnetite, and the main non-metallic mineral is quartz and other iron- and magnesium-type aluminosilicate minerals. After mineral processing tests, the two-stage grinding-magnetic separation-flotation-high-purity iron concentrate dehydration-ultra-pure iron concentrate dehydration-tailings dry discharge process was finalized. Xinhai Mining transformed the existing waste workshop to meet the requirements of the entire production line.

The Xinhai Mining coordinated the planning and effectively ensured the smooth completion and smooth operation of the project with its professional attitude and professionalism, which was recognized and appreciated by the customer.

Xinhai Mining provided the main process production line of the dressing plant, aggregate processing system, tailings transportation system, concentrate storage general contracting project, technical management, debugging and other parts for this project. After debugging and acceptance, it can meet the customer's production needs. The iron ore concentrate product quality is qualified.

Xinhai Mining provides services including mine design, equipment manufacturing and procurement, installation and commissioning for the Xinjiang 1000TPD copper-nickel mine project, and uses professional and mature mineral processing technology and processes to build high-standard green mines. The project is currently in the process of installation and debugging.

In 2023, we were afraid of dangers and move forward courageously, making every effort to ensure the smooth progress of each plant selection project process, always striving on the front line of serving customers, continuously expanding markets and fruitful results, and jointly telling the story of indomitable struggle. Xinhai Mining will keep pace with the times, use struggle as the engine of progress, and innovation as the propeller to keep moving forward!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.