When it comes to Mongolia, the first thing that comes to mind is the endless grassland, barren desert or The Night of Ulabato. It is in this sparser area that there are abundant mineral resources. At present, there are more than 80 kinds of proven minerals, more than 800 mining areas and more than 8,000 mining spots, mainly including copper, iron, coal, manganese, chromium, molybdenum, tungsten, aluminum, tin, placer gold, rock gold, fluorite, graphite and other minerals, most of which are to be mined.

However, Mongolia is lack of professional geological exploration team and technology of mining and mineral processing. Besides, it doesn't have the perfect mine management and operation system to build the modern mineral processing plant independently. In order to promote the mining development of Mongolia and introduce a large number of foreign exploration and technical teams, Mongolia has promulgated the Mineral Resource Law and the Foreign Investment Law, then formulated a series of preferential policies for mineral exploration and development, which undoubtedly attracted the mining personnel from various countries to participate in the mine development of Mongolia.

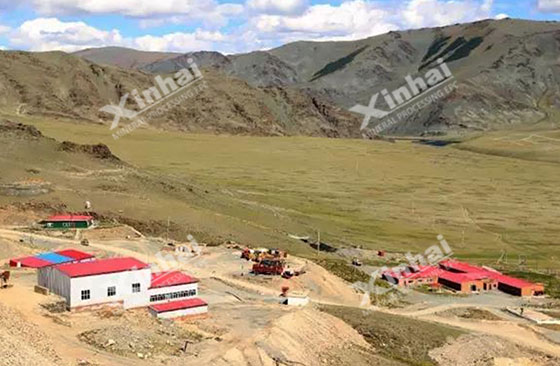

In fact, Xinhai Mining had been involved in the mine development of Mongolia before -- provided mineral processing EPC+M+O service for Mongolian 1000tpd gold mine dressing project. It was proved that Xinhai Mining mineral processing EPC+M+O service was more in line with the mine development status of Mongolia, which completely broke the "fragmentation" mode of traditional mine development and was more systematic and comprehensive.

Entrusted by the company from Mongolia, Xinhai Mining provided the mineral processing EPC+M+O service from design and research, complete sets of equipment manufacturing and procurement, commissioning and delivery to mine management and operation. For the plant design, Xinhai Mining took the gist of pursuing the interests of investors, reducing the investment cost and increasing the benefits, paid attention to the health and safety of workers, environmental harmony, resources saving and recycling, high efficiency and energy saving of single and fleet at the same time, strived for the efficient recycling of gold ore.

According to the results of ore dressing test, Xinhai Mining decided to adopt three stages a closed-circuit crushing and screening - two stages closed-circuit grinding - gravity separation - cyanidation, carbon pulp - desorption electrolysis - tailings dewatering process.

1. Crushing stage:

Three stages a closed-circuit crushing and screening stage. The jaw crusher was used for the coarse crushing. After the coarse crushing, the material was sent to the circular vibrating screen by the belt conveyor for screening I. The sieve material on the upper screen (+30mm) was sent to another jaw crusher for secondary crushing. The sieve material on the second screen (15 to 30 mm) and the sieve material on the third screen (8-15 mm) were transported to the cushion ore bin by the belt conveyor, and then sent to the cone crusher for the fine crushing II by the vibrating feeder. The fine crushing II product was sent to the circular vibrating screen by the belt conveyor for screening II, the sieve material (+ 8 mm) entered into the bar screen for re-screening, the sieve material (+ 20 mm) entered into the crusher for fine crushing I, the products and the screen underflow of bar screen (8 ~ 20 mm) were transported to the cushion ore bin by the belt buffer ore bin before the fine crushing II. The lowest screen underflow of screening I and screening II (-8mm) was the qualified material in the crushing and screening stage.

2. Grinding stage:

Two closed-circuit grinding process. The powder was transported to the wet energy-saving overflow ball mill for one stage grinding by the belt conveyor, and the undersize pulp (-3mm) was pumped into the hydrocyclone for the first stage classification by the slurry pump. The underflow returned to the ball mill for regrinding, forming the first stage closed-circuit grinding.

3. Gravity separation

The first stage of classifier overflow flowed into the original centrifuge for gravity separation. The concentrate and another group of centrifuge concentrate in the original two-stage grinding and gravity separation equipment were distributed together into the shaking table for cleaning. The selected concentrate was granular gold, which can be directly smelted. The cleaner tailings, together with the centrifuge tailings, was put into a pump box, and then pumped into the hydrocyclone for the second stage classification. The underflow and the oversize product of cylinder screen in the first stage closed-circuit grinding flowed into the wet energy-saving overflow ball mill for the second stage grinding. The products returned to the above pump box, forming the second stage closed-circuit grinding.

4. Leaching stage:

The second stage of classifier overflow was sent to the linear vibrating screen (descaling screen) for removing the wood chips, and then flowed to the original thickener for the thickening before the leaching. The overflow was reused as the backwater.

The underflow of thickener (the concentration was about 40-45%) was pumped to the leaching tank by slurry pump for starting the cyanidation leaching operation. To facilitate the slurry flow, the installation height of the former leaching tank was higher than that of the next leaching tank. The sodium cyanide solution flowed into several leaching tanks, and the activated carbon was added to the last leaching tank. After the gold was absorbed by the activated carbon, it was sent to the previous leaching tank by an air lifter. After the gold-loaded carbon was separated by the carbon screen, the pulp returned to the No.2 leaching tank. The gold slime was obtained by the desorption electrolysis of gold-loaded carbon.

5. Desorption electrolysis – smelting stage:

The gold-loaded carbon was sent to the desorption electrolysis system. And the working temperature was about 150 degrees, and the working pressure was about 0.5MPa. then the gold sludge can be produced in only 12-15 hours. The gold sludge produced by electrolysis entered into the smelting stage for smelting and finally the gold ingot was obtained.

6. Tailings dewatering stage:

After leaching, the fine-grained gold-loaded carbon was separated from the pulp by the safe screen, and then the pulp was sent to the filter press by the slurry pump in turn. The filtered tailings were transported to the tailings yard by the belt conveyor. After the filtrate was regularly processed by adding bleach in the sewage buffer tank, it was pumped back to the head tank or directly to the system by the backwater pump for recycling.

The design of this project consisted of mineral processing and smelting, and the final product was gold ingots with the gold grade of more than 95%. While providing the project design and construction services, Xinhai Mining also paid attention to resource conservation and ecological environment protection. In this project, Xinhai Mining provided the perfect tailings dam dry heap and filtrate backwater recycling system, which created favorable conditions for high-quality operation under a green production mode.

Mongolian 1000tpd gold mine dressing project was put into the production in a short period of time, which not only fully reflected the strong mineral processing strength, professional customized solution and thoughtful customer service, but also laid a solid foundation for the further cooperation between the two sides. After the project was put into production, the mining company decided to maintain long-term close cooperation with Xinhai Mining, and hired Xinhai Mining professional technical personnel for technical management. For this reason, Mongolian UBS television conducted an exclusive interview on this project.

Now, with the promotion of the "One Belt And One Road" Initiative, the development speed of Xinhai Mining in Mongolia has been accelerated. Up to now, Xinhai Mining has completed several mineral processing EPC+M+O service projects in Mongolia. More than 2,000 served mines and over 500 mineral processing EPC+M+O service projects covered more than 90 countries and regions around the world.

1. Mongolian 2000tpd gold heap leaching project

Ore property: The accumulative thickness of the main orebody was 120-130m, the grade of Au was 0.81 ~ 1.96g/t.

Xinhai solution: The crushing product adopted three stages a closed-circuit process, multi-layer method heap + spray leaching process. The pregnant solution of heap leaching flowed to the pregnant solution pool. The middle solution of the heap leaching returned to the ore heap for cycle spraying. The pregnant solution used carbon adsorption-desorption electrolysis - smelting process, the carbon absorbed the barren solution then returned to the heap leaching site for cycle spraying, the desorption barren solution was back to the carbon adsorption operation, the electric barren solution returned to the desorption operation, and the alloyed gold was obtained by the fire smelting.

2. Mongolian 500tpd tungsten ore gravity separation project

Ore property: The average content of the third oxidation was 0.2-2.6% in the ore body.

Xinhai solution: two stages closed-circuit crushing - grinding and classification - gravity separation - tailings dewatering process.

The grade of tungsten in the first level of tungsten concentrate was 65.3% and the recovery rate was 72.74%. The grade of tungsten in the secondary level of tungsten concentrate was 15.3%, and the recovery rate was 5.03%. Finally, the project successfully reached the design scale, the annual operating income was up to 15.02 million dollars and the total annual profit reached more than 7 million dollars. Customers were very satisfied with the mineral processing index and economic benefits.

3.Mongolian 150tpd tungsten ore dressing project

Ore property: Tungsten ore was the main mineral with a grade of about 7%. Those particles more than 1mm contained a lot of undissociated tungsten ore and a small amount of tungsten ore in the fine mud.

Xinhai solution: one stage open circuit crushing – one stage closed circuit grinding – gravity separation - tailings dewatering process.

The workshop design fully made the use of the elevation difference and completed the artesian flow layout, and the industrial workshop was made as compact and warm as possible for the winter production. The spiral chute was used in the gravity separation process, which not only effectively reduced the equipment occupation area, but also improved the recovery of tungsten ore by tailings scavenging. In the grinding stage, the wet rod mill with the power of 110kw was used to ensure the optimal dissociation particle size (-1mm) and effectively avoid over-grinding. In addition, the hydraulic classifier and shaking table was added to increase the recovery rate of tungsten in fine mud.

China and Mongolia are friendly neighbors linked by mountains and rivers. Today, China's "One Belt And One Road" Initiative is highly consistent with Mongolia's "Development Road" Plan, which pushes the future development cooperation between the two countries to the next stage, and provides a good opportunity for the mining cooperation between China and Mongolia. In the future, Xinhai Mining mineral processing EPC+M+O service will continue to promote the development of Mongolia's mining industry, and seek cooperation and common development of two nations!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.