Spodumene ore is an important lithium ore used in the production of lithium products such as lithium metal, lithium compounds and lithium-ion batteries. In order to obtain sufficient lithium resources, spodumene needs to be beneficiated, and the equipment used in different stages of the beneficiation process is also diverse. According to the nature of the ore and the designed beneficiation process, choosing the appropriate spodumene beneficiation equipment is an important way to improve the beneficiation effect and economic benefits. Recently, the 2 million TPA spodumene concentrator project in Zimbabwe undertaken by Xinhai Mining has successfully entered the trial production stage. This article will introduce the equipment used in spodumene ore beneficiation according to this case.

The main function of the crushing equipment is to break the spodumene ore from larger lumps into smaller particles for subsequent beneficiation or processing. These crushers are available in different types and sizes, depending on factors such as the hardness of the ore, particle size requirements and processing capacity. The 2 million TPA spodumene concentrator project in Zimbabwe adopts a crushing process of "one stage of coarse crushing, one stage of medium crushing and one stage of fine crushing". The coarse crushing equipment used is a jaw crusher, and the medium and fine crushing equipment are both cone crushers.

The screening equipment is to classify and screen the crushed spodumene ore according to the particle size. This is an important step in the beneficiation process in order to classify particles of different sizes to meet the requirements of subsequent processing or to separate ores of different specifications. The Zimbabwe spodumene concentrator project adopts a "two-stage screening operation", and the equipment uses a banana vibrating screen, which can efficiently complete the product sorting.

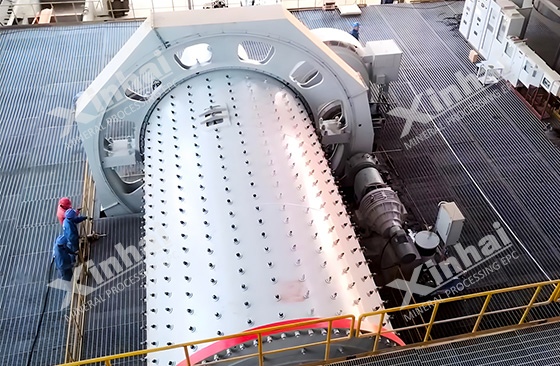

Grinding equipment is used to finely grind spodumene ore to make it reach an appropriate particle size for subsequent processing such as beneficiation or smelting. Grinding is a key link in the beneficiation process. Through fine grinding, the valuable minerals in spodumene ore can be better separated from gangue minerals, and the beneficiation efficiency can be improved. Ball mills and rod mills are commonly used in actual production, which are mainly determined by the ore characteristics of spodumene. In the Zimbabwe spodumene beneficiation plant, Xinhai Mining decided to use a wet grid ball mill to complete the spodumene grinding operation according to the beneficiation test results.

Classification equipment includes hydrocyclones and spiral classifiers, which are used to classify and classify spodumene ore according to physical characteristics such as particle size or density. This is an important step in the beneficiation process to separate spodumene ore into different particle sizes or density levels for further processing or separation of useful minerals and impurities. The grinding and classifying stage of the mineral processing plant in Zimbabwe adopts a one-stage grinding and one-stage classifying process, and a hydrocyclone is used in the classifying stage.

The setting of magnetic separation equipment and desliming equipment needs to be required according to the beneficiation process. According to the beneficiation test results, Xinhai Mining added one stage of magnetic separation and two stages of desliming process to the 2 million tpa spodumene concentrator in Zimbabwe. The main purpose is to remove magnetic impurities and mud in the ore. The main equipment used is magnetic drum and desliming hydrocyclone.

The flotation system is a system for separating spodumene concentrate from gangue minerals. Due to the various types and combinations of flotation equipment, the selection of flotation equipment should be based on the designed selection process. This project adopts one-stage reverse flotation, one-stage positive flotation roughing, three-stage scavenging and three-stage concentrating, and the flotation equipment is set according to this process. In the flotation process, it is necessary to design a chemical agitation tank and a common agitation tank to complete the pulp agitation and drug mixing.

The concentration equipment is to separate the valuable minerals (such as spodumene) from the gangue and impurities in the spodumene ore, so that the final concentrate contains higher spodumene content, which improves the beneficiation efficiency and output. The dehydration equipment reduces the moisture content in the concentrate, making the concentrate suitable for storage, transportation and subsequent treatment. This project adopts the concentration and dehydration process of "thickener + filter press", mainly using hydraulic central drive high-efficiency thickener and chamber filter press.

The above is the equipment used in the 2 million tpa spodumene beneficiation plant project in Zimbabwe. Because the properties of the ore in each mining area are different, the specific equipment configuration should be determined according to the ore beneficiation test results and the beneficiation process design. Xinhai Mining can provide you with "Turn-key Solution for Mineral Processing Plant (EPC+M+O)" including mineral processing test, mineral processing process design, mineral processing equipment production and manufacturing, etc. This time, the Zimbabwe lithium mine project undertaken by Xinhai Mining took only one year from contract signing to trial production, which actually proves the efficiency of Xinhai Mining and the ability and strength of "Turn-key Solution for Mineral Processing Plant (EPC+M+O)".

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.