In the ore-dressing process, ball mill machines are indispensable. Then, how to get a cost-effective and high-efficiency ball mill machine? To improve grinding efficiency, save energy consumption, and protect the environment, Xinhai researches and develops some kinds of high-efficiency and energy-saving ball mill machines. These types of ball mills can be adopted in large, medium, and small mineral processing plants. What’s more, they are on sale at a reasonable and fair price. You can know about the working principle, advantages, and classification of Xinhai ball mill machines from the following.

In the beginning, ore materials are transported into the cylinder of ball mill from the feeding port. Then the cylinder is rotating. Under the action of gravity, the percussive force of medium ( steel ball ), and friction force, the ore stones inside are broken into a smaller size. When the ores are grind to the required particle size, the ore newly entering the ball mill will push them to the discharge port. After discharging, the whole grinding process will be complete.

To some extent, the rotating speed of ball mill machines affects the working efficiency. The high-efficiency ball mill produced by Xinhai equips a cylinder that can rotate 20-40r per minute. What’s more, it can grind the mine materials efficiently. Xinhai high efficient ball mill machine can grind 160t ore materials in an hour. When purchasing the mining ball mill machine, welcome to consult Xinhai.

While designing and manufacturing ball mill equipment, we pay special attention to the machine practicality. Therefore, the ore ball mill machine from Xinhai has strong adaptability. You can use it for many kinds of ore materials grinding. These ores can be divided into metal ore (such as gold, iron, copper, etc.) and non-metallic ore (such as phosphate, graphite, kaolin, etc.). When you want to process the above ores, Xinhai mine ball mill machine will be your good choice. Here are different types, models, and technical parameters of ball mills that you can buy.

When buying the ball mill machine, why Xinhai is your good choice? That is because the ball mill equipment produced by Xinhai has significant advantages. They mainly reflect the following five points. The details are as follows:

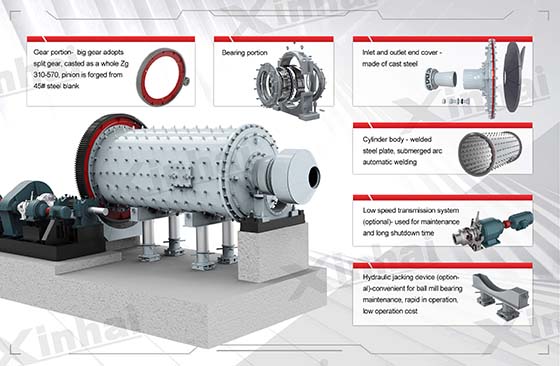

The transmission device of Xinhai high-efficiency ball mill adopts a large double row spherical roller shaft. Compared with sliding bearings, it can reduce the friction force greatly. With this kind of transmission device, the damage risk of ball mill machines will be lower. You can save the maintenance cost of machines. At the same time, you can start the ball mill machine easily and save 20%-30% energy than before. Therefore, you can lower the overall operation cost.

All ball mill machines from Xinhai adopt a waveform lining plate. It can increase the contact area between steel balls and ores stones. What’s more, it can improve the grinding effect. On one hand, the waveform lining plate can improve the working efficiency of ball mill equipment. On the other hand, it can lower the energy consumption of ball mill. The waveform liner is also not easy to fracture, can effectively avoid the production stagnation caused by lining fracture.

While designing the ore ball mill machine, Xinhai adopts the design of a big discharging port. This structure can make the ball mill discharge much more efficiently. Because the large discharge outlet is not easy to block.

Xinhai installs a fog lubrication device on the ball mill machine. This device can ensure the normal operation of cylinder on the ore ball grinding machine. At the same time, it can make the gears on the machines get normal lubrication.

The ball mill machine with a length of less than 2.1m adopts an integrated rack. By doing so, you can install the machine conveniently and reduce the cost of civil construction.

With the above five outstanding advantages, the high-efficiency ball mill machine from Xinhai is welcomed by large, medium, and small-sized ore dressing plants. What’s more, Xinhai ball mills are exported to over 90 countries and regions at home and abroad.

To meet the requests of mineral processing plants with different scales, Xinhai designs and manufactures many types of ball mill machines. According to different grinding processes, the ball mills manufactured from Xinhai can be divided into two types: wet type and dry type. The wet-type ball mills can also be two classifications. One is grid type ball mill, and the other is overflow ball mill. Both of them have advantages and characteristics. The specific introductions are as follows.

It adopts a mandatory discharge method. The machine is widely used in ore processing production lines which require big ore particles and high yields.

Different from the grid ball mill, the machine adopts a self-discharging method. This kind of ball mill machine is more suitable for the mineral processing company which requires finer ore particles.

The customers can buy the right ball mill machines based on the particles size of finished products and processing capacity. In Xinhai, you can find 0.14-170t/h mine ball mill machines. Welcome to visit and purchase Xinghai ball mill machines.

Xinhai, an ore ball mill manufacturer with over-20-year experience in production, can provide you with quality and efficient machines for ore grinding. What’s more, Xinhai is the first EPC+M+O provider for mine design, research, equipment manufacturing, installation and commissioning, and staff training. We have completed over 500 ore dressing projects around the world. You can trust our technologies and services completely. Welcome to visit our official website for more details.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.