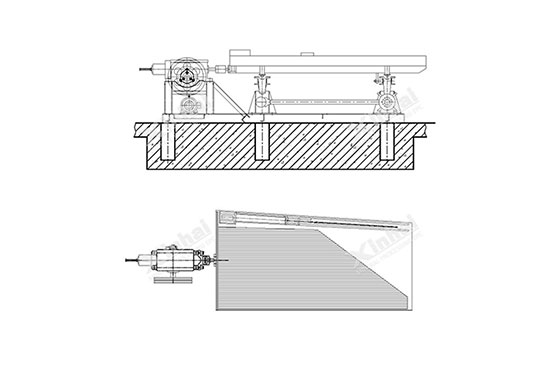

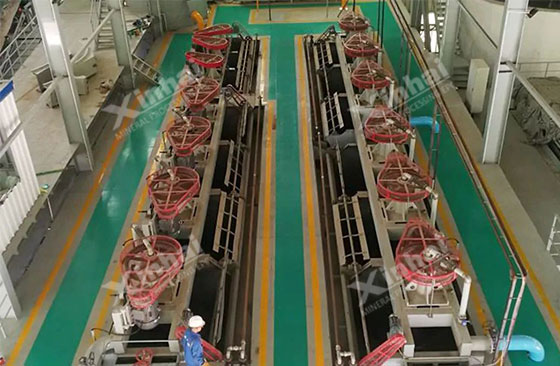

Shaking table, also called concentrating table, is one of the most wildly used gravity separators. The concentrating accuracy and concentrate enrichment ratio are high. During the operation of the shaking table, the minerals are separated through both the movement of the table surface and the wash of horizontal water flow. To reduce the accident and increase the concentrating efficiency, the operators should understand the operating skills and maintenance points.

During the operation of concentrating table, the operators should observe the shaking table bed surface partition and control the suitable bed surface longitudinal and transverse slope carefully. Besides, it is also necessary to consider such factors as feed size, feed amount, feed concentration, flush water, stroke and impulse secondary during the sorting process. Below we according to the above several main factors, to skills to the operation of the shaking table are explained simply.

In the bed surface is divided into concentration area, middling area, tailings area and slime area. Under normal circumstances, the width of the slime is 0.9 ~ 1.4 m. Mine tailings area flow to smooth and does not produce the rapids or pull ditch phenomenon, the thickness of the seam should be appropriate, should be covered by water. Tailings can be controlled by adjusting feed concentration and feed channel sand hole. In the mining area is separated middlings range, the main control by adjusting rinse water and transverse slope. The selection area requires a clear zonation of various specific gravity minerals, forming a stable and distinct boundary between the selection area and the primary concentration area, which is controlled by the adjustment of flushing water and the lateral slope.

During equipment installation, the longitudinal slope determines. The coarse sand area has a longitudinal inclination of 1° ~ 2°, the fine sand area has a slope of 0.5° ~ 1.0°, and the mud area has no slope at all. The bed surface is laterally inclined from the feeding end to the opposite side at 1.5°~5°. In the actual operation of the shaker, the longitudinal and transverse slopes of the bed surface need to be precisely controlled. Generally, if the mineral particles are coarse, the horizontal slope of the bed surface of the shaker should be raised appropriately. On the contrary, if the mineral particles are finer, it is necessary to lower the horizontal slope of the bed surface. Generally, the horizontal slope ranges of coarse sand area, fine sand area and mud area are 2.5° ~ 4.5°, 1.5° ~ 3.5° and 1° ~ 2° respectively.

Feeding size should be appropriate. The upper limit of feed size is 2~3mm, and the lower limit is 0.037mm. Generally, pre-grading ensures the uniform particle size at all levels. In order to ensure the uniform particle size at all levels of the shaker, and the feeding particle size is within the appropriate range, it is necessary to observe the ore belt in the concentrate belt and wash the tailings.

The size of ore feed is related to the size of feed grain. If the ore grains are thicker, the more ore is needed. However, if the amount of ore is too large, it will lead to zoning problems, in which case, it is necessary to move the concentrate interceptor plate, increase the flushing water and the horizontal slope of the bed surface of the shaker. It is important to note that once the correct amount of ore is found, the ore feeding process should be continuous and uniform.

During the sorting process, the appropriate concentration of ore must be ensured. In general, the concentration of coarse and fine minerals is 20% ~ 30% and 15%~25%, respectively. When the shaking table bed surface pull ditch problem, can be appropriately adjusted to increase feed concentration; On the other hand, if there is a sand pile, then the ore concentration needs to be reduced. Feed concentration can be controlled by adjusting feed water amount.

Flushing water includes feed water and washing water. During the operation of the shaker, when the concentrated zone Narrows and the concentrate runs into the middle ore, the flushing water amount needs to be reduced. Conversely, if there is no water shaker bed surface-exposed film, it needs to increase the appropriate amount of water. When controlling the flushing volume, the pulp velocity and the concentration zone width should be carefully observed.

The length and frequency of the stroke are mainly affected by the inclusion of mineral particle size, bedload and the density of ore. When choosing materials with coarse grain and thick bed, large stroke and small stroke should be used. Otherwise, you need to use a short and frequent stroke. When a fault occurs, it is necessary to check whether the stroke is appropriate or not.

1. Periodically check that all parts are in good condition, including the bed surface, the head of the bed and the rack of the shaker. First need to check whether the bed surface of the shaker contact non-shaking parts, bed surface tilt, if found that the surface of the shaker is damaged, can prepare resin filler wear-resisting agent for repair.

2. Check the wear condition of the part of the head of the bed. When the wear condition of the part is found to be very serious, it should be replaced in time.

3. Check whether the screw is loose, the position of the tie rod, whether the spring is damaged, and whether the sliding surface of the shaker is good. If there is abnormal sound, it should be found and eliminated in time.

4. When the storage box is shaken, special attention should be paid to prevent deformation of the bed surface of the shaker.

5. When parking, in order to avoid the oxidation of impurities and scale, we need to use water to clean the bed surface of the shaker. If scaling occurs, it should be removed in time.

In order to improve the working efficiency of the shaking table, Xinhai mineral assembly processing engineers suggest, in full consideration of the actual situation, you can refer to the above operation skills and maintenance points to reasonable use of the shaker, reduce and solve various problems in the process of sorting.

1. Guinea 6000tpd gold processing project

2. Yunnan 4400tpd copper processing project

3. Pakistan 1500tpd copper processing project

4. Armenia 1500tpd Cu--Pb-Zn processing project

5. Tanzania 1200tpd gold processing project

6. Mongolia 1000tpd gold processing project

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.