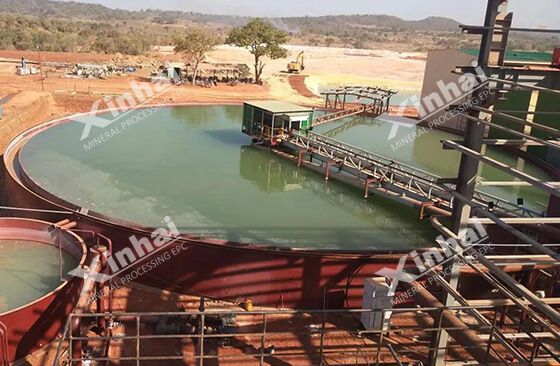

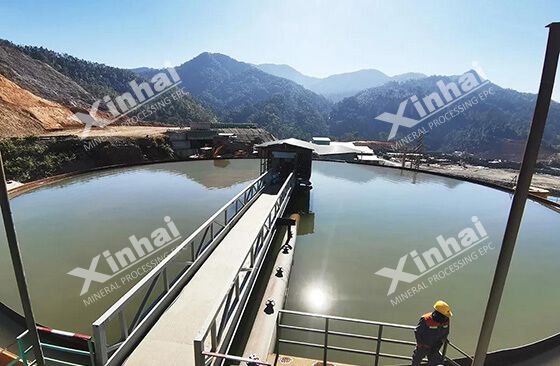

The thickener is a solid-liquid separation equipment based on the gravity sedimentation, and is also a thickening equipment commonly used in the concentrators. In the practical application, most concentrators will encounter the various thickener problems, which will not only affect the normal operation of concentrators, but also seriously damage the economic benefits of concentrators.

Next, we will take you to understand three common thickening equipment problems, analyze their causes in detail and give the corresponding solutions.

In the production, the muddy overflow water is one of the common faults of thickener, that is, the thickener cannot carry out solid-liquid separation well, and the overflow is muddy. Here are the causes and solutions of this problem:

Main reasons:

■The slurry properties that fed into the pool cause the muddy overflow. For example, the slurry is mixed with a certain amount of air, and the intervention of air makes the slurry produce a large number of bubbles in the mixed stratification. In addition, if the slurry contains too much mud, it will also make the overflow difficult to clear, especially the fine slime (0.1-0.001μm).

■If the processing capacity is too large, the slurry in the pond will produce a large intensity of turning over or the underflow control is too small, which will also easily cause the muddy overflow.

■The improper regulation of settling layer causes the muddiness. If the underflow discharge is too large and the settling layer is too thin, some fine ore particles enter the overflow because of poor filtration effect. On the contrary, the too thick settling layer will block most of the pooled water in the settling layer, so that the position of settling layer floats.

Solutions:

1. Eliminate the adverse factors of pooled slurry. For example, the welding frame degassing tank can be used to eliminate the air inclusions in the pulp before entering the pool. For the fine slime of 0.1-0.001μm, adding the flocculant to make the fine slime form the agglomeration and accelerate the settlement to avoid the muddy overflow.

2. Ensure that the processing capacity of thickener matches the process production capacity. The processing capacity of the thickener shall refer to the related parameters of the hydrocyclone (the overflow of the hydrocyclone is the feeding capacity of the thickener). In addition, the thickening underflow should not be adjusted too small, avoiding the muddiness of ore-accumulation.

3. Adjust and control the settling layer to maintain the thickness of 200-300mm. When the sediment layer is thin, the discharge quantity of underflow can be reduced, otherwise, it should be increased appropriately.

During the operation, the thickener operator shall regulate and control the technical parameters provided by the professional thickener manufacturer, ensuring the coordination among the technical parameters.

Main reasons:

■Improper lifting of rake frame. If the rake frame is not raised after the power failure, it is possible to damage the cochlear gear by directly starting the motor after the power failure.

■The improper concentration ratio means the concentration ratio deviates the technical standards obviously. If the concentration ratio is too large, maybe the pooled concentration is too thin or the concentration after thickening is thick, which clogs the underflow discharge pipe. If the concentration ratio is too small, maybe the feeding concentration is too large or the discharging concentration is too small.

■There is no observation hole in the side wall of the thickener, so it is impossible to directly observe the thickness of the clarifying layer and the filter settling layer in the tank, which brings a lot of inconvenience to the operation and control, leading to the stratification disorder in the tank.

Solutions:

1. Timely lifting the rake frame to adjust the speed. If the power failure occurs suddenly in the operation, it is necessary to manually reverse rotate the rake frame to make it rise, and then downward after the call.

2. Adjust and control the concentration ratio to 2.0-2.3, making it meets the technical standards. The concentration ratio is an efficiency index to check the precipitation difficulty of pulp in a certain period of time. Most concentration-washing are from the hydrocyclone feeding, so the concentration before thickening is the overflow concentration of the hydrocyclone, and most of them require about 20%, while the concentration of the product after thickening is 40-45%.

3. At present, the side wall of the new type thickener is equipped with plexiglass observation holes to adjust the thickness of the clarifying layer and the filter settling layer, so that they are kept within the standard range of 250-550mm respectively.

■In the thickening process, the uneven addition of flocculant is also a common problem, which will directly affect the settling efficiency of the thickener.

Main reasons:

■The wrong addition way. If add the flocculant first then add water, or add the flocculant while add the water, even one-time add the flocculant to the tank will make the agitation liquid uneven. Sometimes, there are obvious flocculated insoluble matter in the tank, which is not conducive to the concentration and precipitation.

The flocculant takes too long to dissolve. After the stirring and dissolving, if the flocculant doesn’t dissolve completely after 8 hours, the normal production of thickener will be affected.

Solutions:

1. Add the flocculant correctly. Fill the tank with water to the blade position, shake the sieve and slowly pour in the flocculant until the flocculant is finished. Please note that the flocculant cannot be damp or floccus, or directly added one-time pour. At the same time, Be aware of spillover due to excessive liquid injection in the tank

2. Shorten the dissolving time. The speed of agitation tank can be increased to facilitate the uniform diffusion of the agent in the tank.

The reasons and solutions of three common problems of thickening equipment are introduced above. When the thickener breaks down, the thickener operator should carefully analyze the causes, then adopts the corresponding solutions, and pay attention to the daily maintenance and overhaul of the thickener in the actual production, ensuring the smooth operation of the whole concentrator.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.