The spodumene flotation usually requires the use of flotation reagents to achieve the purpose of effectively separating spodumene from other minerals. The choice of flotation agents depends on the specific ore composition and processing conditions. Commonly used spodumene flotation reagents can be divided into collectors, frothers, and modifiers. The following will introduce the commonly used reagents for spodumene flotation around these three reagents.

A collector is a chemical that increases the hydrophobicity of the spodumene particles, allowing them to attach to the air bubbles during flotation. Commonly used spodumene flotation collectors include fatty acids and their derivatives, such as oleic acid, sodium oleate, or tall oil fatty acids. These collectors adsorb on the surface of the spodumene particles, making them hydrophobic for easy binding with air bubbles.

1. Oleic Acid: Oleic acid is a commonly used spodumene collector. It can be adsorbed on the surface of spodumene ore particles, making it hydrophobic, thereby promoting spodumene to combine with air bubbles and float.

2. Sodium Oleate: Sodium oleate is the sodium salt form of oleic acid, which has similar collection properties. It can be used in the flotation process of spodumene ore to realize the attachment and flotation of spodumene and air bubbles.

3. Tall Oil Fatty Acids: Tall Oil Fatty Acids is a mixture of fatty acids extracted from the woody part of pine trees. It is used as a collector in spodumene flotation, which can enhance the adhesion between spodumene particles and air bubbles, so as to achieve effective flotation separation.

4. Mixed Collectors: Sometimes, in order to improve the flotation effect of spodumene ore, a mixture of multiple collectors can be used. For example, the combination of oleic acid and abietic acid can produce a synergistic effect, improving the flotation recovery and selectivity of spodumene.

A frother is a substance that stabilizes the air bubbles produced during flotation, promoting their persistence and stability. A good frother can reduce the fusion of air bubbles and improve the flotation kinetics. Commonly used frothers in spodumene flotation include isobutanol methyl ether (MIBC) and pine oil.

1. Methyl isobutanol (MIBC): MIBC is a widely used foaming agent in spodumene flotation. It has excellent foaming properties that help create and stabilize small, persistent bubbles that promote the attachment of spodumene particles to the bubbles and their buoyancy to the liquid surface.

2. Pine oil: Pine oil is a foaming agent commonly used in spodumene flotation. It is extracted from pine trees and is used as a foaming agent to create and stabilize air bubbles. Pine oil enhanced the flotation kinetics and improved the separation efficiency of spodumene particles.

3. Ethanol (alcohol): Ethanol can also be used as a foaming agent in spodumene flotation. It helps to form a stable foam and facilitates the selective flotation of spodumene particles with air bubbles, allowing the particles to attach to the air bubbles.

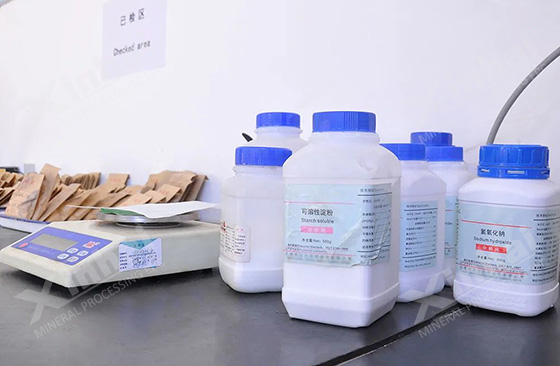

Modifiers are used to adjust the pH value of the flotation liquid or change the surface properties of minerals to improve the selectivity of spodumene flotation. Modifiers commonly used in spodumene ore mainly include the following:

1. pH regulator: The pH regulator is used to adjust the pH value of the solution during the flotation process to optimize the flotation effect of spodumene. Commonly used pH adjusters include sulfuric acid and sodium hydroxide. By controlling the pH of the flotation slurry, the charge properties on the surface of the ore can be adjusted to affect the adsorption and flotation performance of the ore and the collector.

2. Inhibitors: Inhibitors are used to inhibit the flotation of certain minerals to ensure the selective flotation separation of spodumene. During the spodumene flotation process, there may be some interfering minerals, such as iron minerals or silicate minerals. By adding inhibitors, the flotation of these interfering minerals can be reduced, and the purity and recovery of spodumene can be improved. Commonly used inhibitors include sodium silicate, sodium carbonate and the like.

3. Activator: Activator is used to improve the flotation performance of certain minerals or improve their response to collectors. In spodumene flotation, the use of activators is generally not required. However, in some special cases, a small amount of sodium fluoride or sodium carbonate can be added as an activator to improve the flotation recovery and selectivity of spodumene.

The above content is commonly used reagent collectors, foaming agents and modifiers for spodumene flotation. The selection and dosage of specific flotation reagents may vary depending on the specific ore characteristics, process configuration and desired flotation performance. Therefore, it is necessary to conduct beneficiation test analysis and beneficiation process optimization research to determine the spodumene flotation agent scheme suitable for the specific production process and realize the effective flotation separation of spodumene ore.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.