As an important industrial metal, tin is widely used in electronics, chemical industry, food packaging, national defense and other fields because of its low melting point, excellent plasticity, corrosion resistance and non-toxicity. Although tin has made significant contributions to social development, tin ores in nature usually coexist with a variety of impurity minerals and cannot be directly utilized. In order to effectively extract metallic tin from the ore, mineral separation processes such as gravity separation, flotation and magnetic separation can be used. These processes can effectively separate valuable tin minerals based on different ore characteristics, while removing impurities to ensure that the concentrate products meet the quality requirements of industrial production.

In China, placer tin ore is the main form of tin ore resources, accounting for more than 80%. Since the density of cassiterite is significantly greater than that of paragenetic minerals and gangue, gravity separation has become the preferred process for processing tin ore. Before gravity selection, the multi-stage grinding and multi-stage sorting strategy ensures early dissociation and recovery of cassiterite and avoids over-crushing. In addition, the fine-grained sludge (40~60%-10 microns) commonly found in raw ores also interferes with mineral processing, so pre-selection desliming operations are required, including the two stages of sludge dissociation and dispersion and mud and sand separation, aiming to remove the Fine mud balls on coarse particles to ensure that the material size is suitable for re-selection.

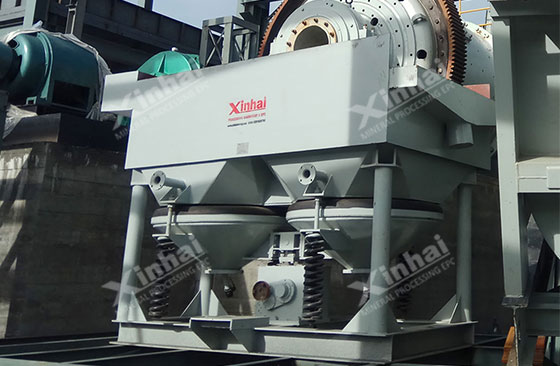

The tin ore gravity separation process achieves separation based on the difference in specific gravity between tin ore and gangue and the different settling speeds in the medium. The gravity selection process usually includes rough selection and fine selection. In the rough selection stage, a jig is used to pre-select and discard tailings. The minerals are stratified according to specific gravity through up and down pulsating water flow, and coarse and medium-sized tin ores are efficiently processed. For fine-grained tin ore, shaking table selection is used, relying on asymmetric reciprocating bed motion and water flushing to achieve high-precision separation, which is especially suitable for the recovery of fine-grained cassiterite from cassiterite-quartz type ores. Overall, the tin ore beneficiation process is flexibly adjusted based on actual conditions to ensure efficient recovery of tin resources.

When the cassiterite particle size is refined to less than 19μm, the gravity separation efficiency is limited, and flotation becomes the preferred option. In the cassiterite flotation process, select a suitable collector, adjust the pH value of the pulp, and inhibit the associated minerals. Commonly used collectors include oleic acid, toluene arsenic acid and salicylic hydroxamic acid, and adjusters are commonly used sodium hydroxide, sodium carbonate and sulfuric acid. By controlling the pH value and selectively adding inhibitors such as water glass and sodium hexametaphosphate, the concentrate grade and recovery rate of cassiterite flotation can be effectively improved.

Effective separation can be achieved by adopting flocculation flotation and carrier flotation process methods. Flocculation flotation adds selective flocculants to flocculate the target minerals into agglomerates, thereby achieving separation from gangue minerals; carrier flotation uses minerals of general flotation particle size as carriers to float fine-grained tin ore together with the carriers, thereby achieving recovery. In addition, shear-flocculation flotation uses the shear force generated by strong stirring and the collector to form hydrophobic bonding force on the surface of the ore particles, promoting the formation of flocs of fine ore particles, and can also effectively separate and recover tin ore. For tin ore with uneven particle size, it is recommended to use a combined process of gravity separation and flotation, supplemented by a process of first floating and then re-gravity of fine ore, to optimize the mineral processing indicators.

Tin ore is usually associated with iron oxide minerals (such as magnetite, hematite, limonite) and tungsten ore. These complex intergrowth minerals make it difficult to achieve ideal separation effects by flotation and gravity separation. Therefore, magnetic separation method is used. According to the properties of different tin ores, the choice of magnetic separation process is also different. If the associated mineral is tungsten ore, a dry magnetic separation process can be used to separate wolframite, scheelite and cassiterite, and then further separate cassiterite and scheelite through electric separation. If the associated mineral is iron oxide, a wet strong magnetic separation process is usually used. Wet strong magnetic separation is widely used in the pretreatment of raw ores, sub-concentrates and concentrates, aiming to achieve effective separation of tin and iron.

As a key step before separation, raw ore magnetic separation can be regarded as magnetic classification. The ore is divided into magnetic and non-magnetic parts, which enter the gravity separation process respectively. The processing of the non-magnetic part is relatively simple, and the recovery rate and concentrate grade are high; the processing of the magnetic part is more difficult, and it mostly produces rich or poor medium ore. The secondary concentrate has a higher iron mineral content and the magnetic separation effect is more significant. Although the magnetic separation of concentrate strives to separate the cassiterite and iron minerals individually, the risk of over-crushing of cassiterite needs to be balanced. In practice, iron mineral combinations are often accepted into the concentrate to reduce the degree of cassiterite crushing.

Tin is a widely used metal. In order to ensure that the tin ore can meet the expected beneficiation effect after it is put into production, it is necessary to conduct tin ore beneficiation tests, and determine the specific process flow and select the appropriate equipment configuration based on the test results. Through this process, the beneficiation efficiency can be optimized and the tin metal recovery rate can be increased, thus ensuring that the tin ore processing is both economical and efficient.

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.